Best 3 axis CNC milling machine

Are you looking for the right 3 axis CNC milling machine or machining center? Then you are in the right place.

As we all know, 3 axis CNC milling machine is the most widely used metal processing machine, which is suitable for various industries including medical, mold, automobile, 3C, aviation and other industrial fields.

TAICNC, as a leading 3 axis CNC milling machine manufacturer and supplier in China, provides high-quality and affordable 3 axis CNC milling machines to global customers, and is currently selling at manufacturer’s prices.

3 Axis CNC Milling Machine for Sale

There are many specifications of 3 axis CNC milling machine, you can check the specifications we have listed below, or you can contact us to send your specification requirements, we have many 3 axis CNC milling machines but not all specifications are uploaded to the website.

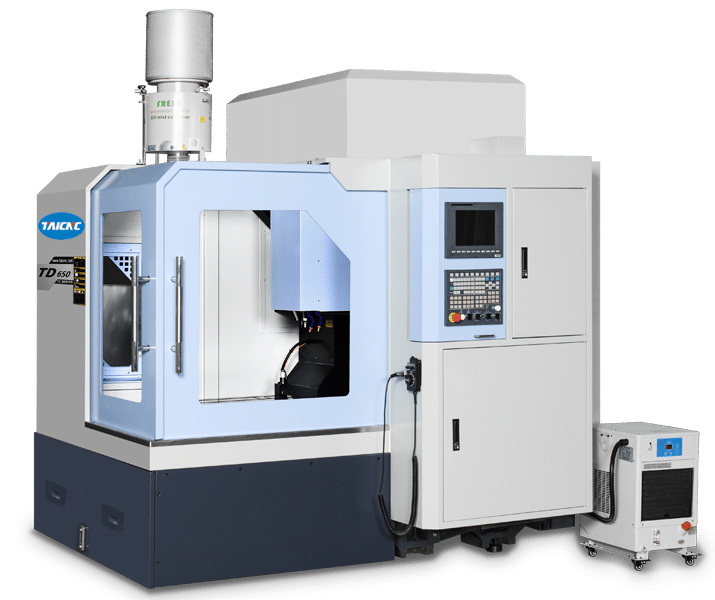

TD-650 High Speed CNC Engraving Milling Machine

Read More →

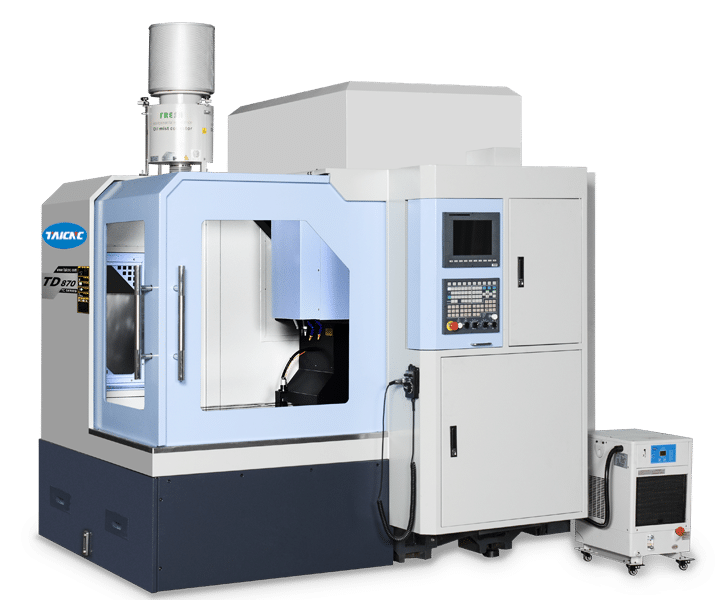

TD-870 High Speed CNC Engraving Milling Machine

Read More →

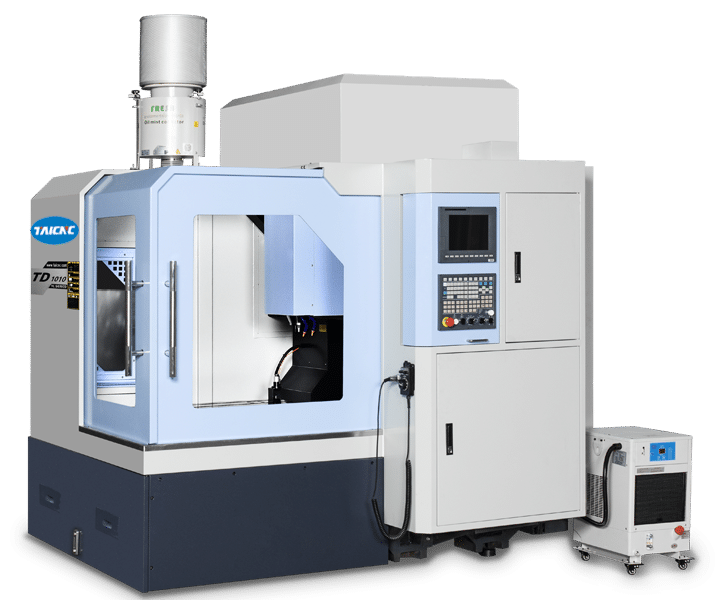

TC-V11 High-speed CNC milling machine

Read More →

TD-1285 High Speed Double Column Machining Center

Read More →

T7V Small CNC milling machine & tapping center

Read More →

T10V small CNC milling machine & tapping center

Read More →

TC-855L Vertical Machining Center

Read More →

T8V Small CNC milling machine & tapping center

Read More →

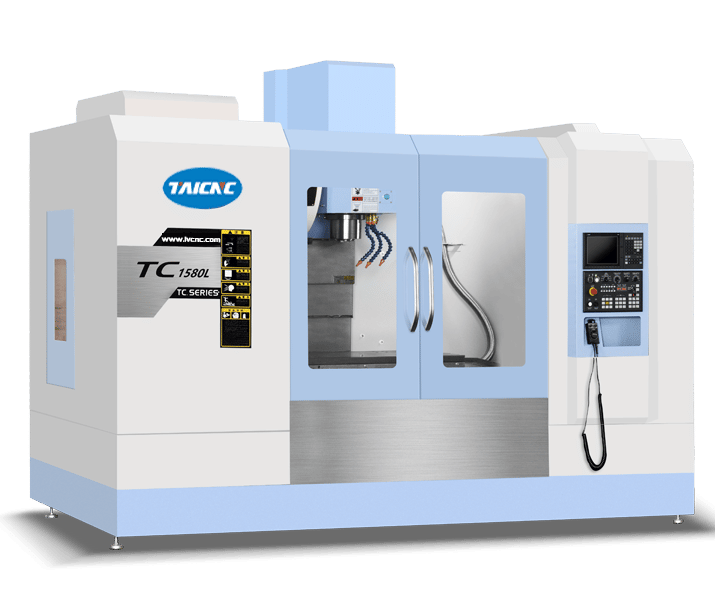

TC-1580 Large CNC Machining Center

Read More →3 Axis CNC Milling Machine Guide

Are you looking for a 3 axis CNC milling machine at an affordable price? Do you know enough about it, whether you are an amateur or a professional practitioner, you should know enough about it.

Below we will introduce the most complete 3 axis CNC milling machine guide for you. After reading it, you can get all the knowledge of 3-axis CNC milling machines, including 3-axis CNC milling machine prices, uses, definitions, etc.

1. What is a 3 axis CNC milling machine?

3 axis CNC milling machine, also called 3 axis vertical machining center, is one of the most common CNC milling machines.

A 3 axis CNC milling machine is a computer-controlled tool used for cutting and shaping solid materials like metal, wood or plastic.

It has three moving parts, or axes, that allow it to move the cutting tool in three different directions: up and down, side to side, and forward and backward.

This allows it to create complex 3D shapes with precision and accuracy. The machine is controlled by a computer program that tells it exactly how to move and what to cut, making it a powerful tool for manufacturing and prototyping.

2. Use and Function of 3 axis CNC Milling Machine

A 3 axis CNC milling machine is a tool used to cut and shape materials like metal, wood, or plastic. It uses computer-controlled motors to move a cutting tool along three different directions, allowing for precise and accurate cuts in three dimensions.

For example, if you wanted to create a three-dimensional object out of a block of metal, a 3 axis CNC milling machine could be used to carve away excess material in a precise manner, creating the desired shape. The machine can also be programmed to create complex shapes, repeating the same pattern over and over with consistent accuracy.

CNC milling machines are commonly used in industries such as manufacturing, engineering, and prototyping to produce parts or objects with high precision, efficiency, and speed. The use of a CNC milling machine reduces the amount of manual labor required and allows for the production of more complex designs.

Usually 3-axis CNC milling machine has the following functions:

- Milling: Milling is the primary function of a 3-axis CNC milling machine.

- Drilling: Drilling is more efficient with a 3-axis CNC milling machine

- Tapping: with rigid tapping function

- Cutting: use tool to remove sharp edges

- ATC: Automatic tool change

In actual processing, the 3-axis CNC milling machine can only process one side of the part at a time. If you need to process other sides, you need to re-clamp the part, or you can choose a 4 axis CNC milling machine or a 5 axis CNC milling machine.

3. Benefits of using a 3 axis CNC mill

3-axis machining is one of the most widely used techniques for manufacturing mechanical parts.

Are you still making parts with a transmission manual milling machine?

When you use the 3-axis CNC milling machine for the first time, you will find that it has many benefits, as follows:

- Increased precision and accuracy due to computer control and automated tool changes.

- Greater speed and efficiency in production as a result of automated operation.

- Ability to produce complex shapes and features with ease and consistency.

- Reduced operator error and fatigue, as the machine performs the repetitive work.

- Option to integrate with computer-aided design (CAD) and computer-aided manufacturing (CAM) software for more advanced programming and customization.

- Improved safety as there is less operator contact with cutting tools.

4. What is the price of 3 axis CNC milling machine?

Learned about the 3-axis CNC milling machine, isn’t it perfect? Would love to have it right?

Let’s talk about the price of 3-axis CNC milling machine below.

Many people think that the price of 3-axis CNC milling machines is too high. In fact, due to the rapid development of industry and technology in recent years, the price of CNC milling machines has been declining year by year.

The price range of 3-axis CNC milling machines in the market can vary depending on a variety of factors, including the machine’s size, capabilities, and brand. Here is a general breakdown of the price ranges you might expect to see for different types of 3-axis CNC milling machines:

- Entry-level hobbyist machines: $1,000 – $10,000

- Mid-range machines for small to medium-sized businesses: $10,000 – $50,000

- High-end machines for industrial use: $50,000 – $500,000 or more

It’s important to note that these are general price ranges, and there may be machines available at higher or lower price points within each category. Additionally, prices can fluctuate over time and may differ based on the specific machine and supplier.

You may have noticed that these price ranges are quite wide. There are many factors that affect the price of 3-axis CNC milling machines, as follows:

- 3-axis CNC milling machine specifications (X, Y, Z axis processing range)

- Spindle speed (faster speed = better accuracy)

- Machine moving speed (the faster the moving speed, the higher the efficiency)

- Machine power (servo motor size, spindle torque)

- Automatic tool changer (tools can be changed automatically during processing)

- Country of Manufacture (Korea, China, Taiwan vs Japan, Germany)

- Tariff

- freight

- Options (such as automatic chip removal system, detection system, oil mist collector, 4-axis rotary table, 5-axis rotary table, etc.)

5. How to choose the right 3-axis CNC milling machine?

A 3-axis CNC milling machine is an expensive investment.

Whether you are a hobbyist or a professional practitioner, there is a certain level of expertise required.

How to choose a suitable three-axis CNC milling machine is a must-know knowledge, especially for novices who have not been exposed to 3-axis CNC milling machines.

How to choose a suitable 3-axis CNC milling machine needs to make a decision according to its own actual situation, as follows:

- What is the size of the machine required (depending on the part being machined)?

- Machining efficiency required (how long do you expect to complete a part)?

- Need an automatic tool changer?

- Required spindle speed?

- What materials are used for processing?

- What is the required precision?

- Your price budget?

Only when you fully understand your needs can you choose the right CNC machine. Too cheap or too expensive is not an ideal choice.

- Amateurs: For amateurs, we usually recommend desktop mini3 axis CNC milling machines or 3 axis small CNC milling machines. They have a small footprint and are economical.

- Personal studio: Personal studios We recommend 3 axis small CNC milling machines or 3 axis machining centers for their precision and stability.

- Manufacturing plant: The manufacturing plant has complete facilities and factory area. All 3 axis CNC milling machines are suitable for practical needs.

6. Conclusion

After reading the above content, do you have a comprehensive understanding of the three-axis CNC milling machine? If you are meeting him for the first time, please do not buy blindly. You need at least some knowledge of programming to be good at it.

A 3-axis CNC milling machine is also worth investing in. It can do a variety of manufacturing jobs, and it can also be extended with accessories to complete 4-axis or 5-axis machining, which will be more efficient.

If you have more questions about the 3-axis CNC milling machine, please contact our experts for more professional answers.

Rating

Your page rank: