Contact us to get expert advice and the best offer for you

CNC milling machines can quickly grow your metalworking business, if you are looking for CNC milling machines, you are in the right place.

TAICNC is a leading CNC milling machine manufacturer and supplier in China. With 20 years of CNC machine tool manufacturing experience, our CNC milling machines are widely praised by customers around the world.

Whether you need vertical CNC milling machine, horizontal CNC milling machine, small CNC milling machine, double column CNC milling machine or CNC tapping center, we can meet your needs, our CNC milling machines are widely used in various metal parts and mold manufacturing, and sold at manufacturer price

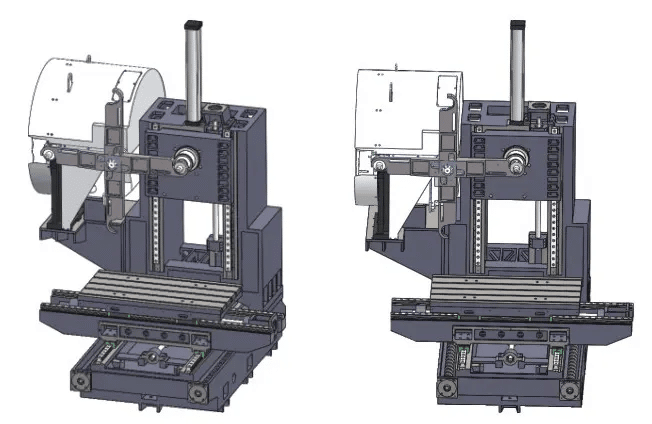

TAICNC is an expert in the manufacture of CNC vertical milling machines, and the CNC vertical milling machines we manufacture are suitable for all walks of life.

Whether you’re making parts or making molds, they’re your best partner.

We have CNC vertical milling machines in various sizes for various industries, including high-speed precision machining and heavy-duty milling, with good reliability.

Over the years, we have undergone rigorous validation to ensure that our vertical machining centers provide our customers with continuous performance. Every vertical machine is rigorously tested before leaving the factory.

From small CNC milling machines to large CNC milling machines they can meet your needs 100%.

As a leading CNC horizontal milling machine manufacturing expert in China, our CNC horizontal milling machines cover most of the machining needs.

TAICNC has been committed to developing and manufacturing HMC machines that satisfy customers from the actual processing needs.

Ordinary CNC vertical milling machines are limited by the height of the column and the automatic tool changer. It can’t handle parts that are too tall.

The CNC horizontal milling machine solves this problem, and the CNC horizontal milling machine can also complete multi-sided processing in one clamping. Because it has a turntable that can rotate 360 degrees.

CNC double column milling machine It is the largest CNC machine tool ever manufactured.

It is the same as the CNC vertical milling machine, the spindle is processed vertically downward.

TAICNC manufactures small CNC double column milling machines and large double column milling machines.

Small double column milling machines are products that replace large vertical machining centers. Especially for processing large metal blocks, the double-column milling machine is obviously more advantageous.

Sorry, we couldn't find any posts. Please try a different search.

Contact us to get expert advice and the best offer for you

TAICNC is a leading CNC milling machine manufacturer in China. The CNC milling machines we manufacture are mainly vertical CNC milling machines and horizontal CNC milling machines, commonly called vertical machining centers and horizontal machining centers, both of which have great advantages.

TAICNC T series CNC tapping center has a small footprint. Ultra-compact high-speed CNC tapping center. 12,000 to 20,000 RPM BT30 spindle capable of rigid tapping at 6,000 RPM. If you are looking for efficient yet affordable CNC tapping and drilling centers, our T-Series is your best choice. High performance CNC tapping center with leading BT30 spindle processing capacity and tool storage capacity to achieve high productivity.

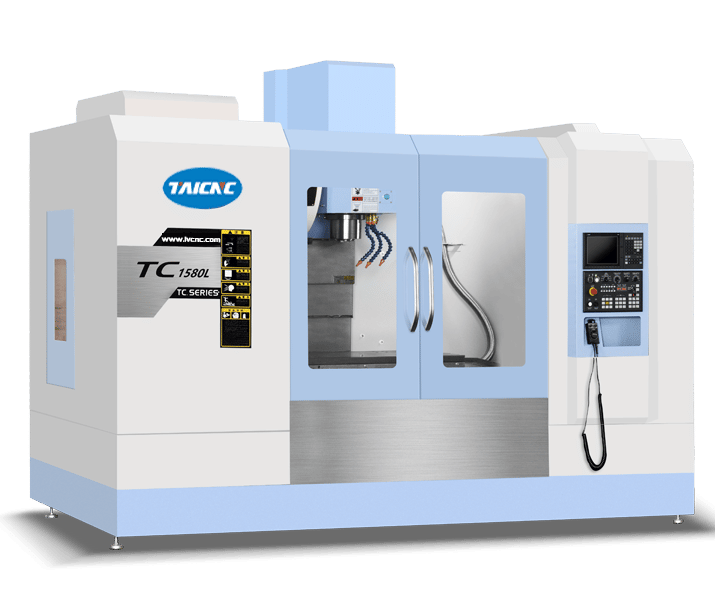

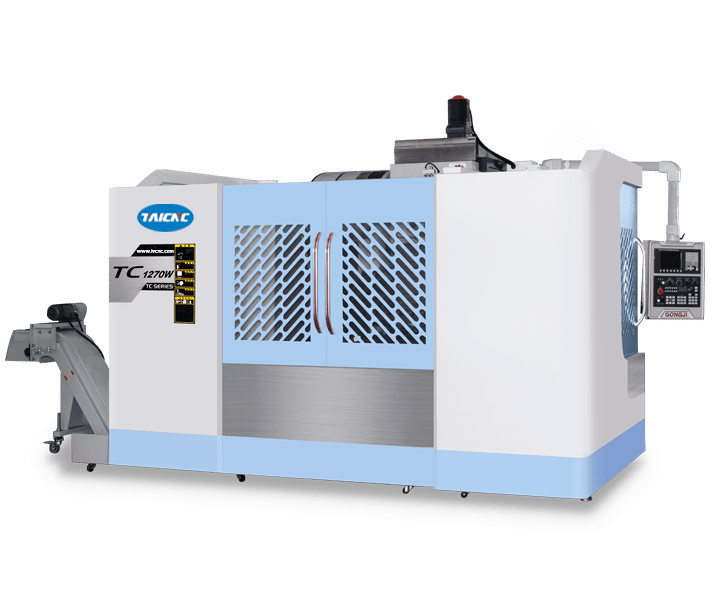

TAICNC TC series CNC milling machine is also known as vertical machining center or VMC machine. They are the first choice for various parts and mold processing. Whether you need heavy cutting or precision machining, they will fit your needs well.

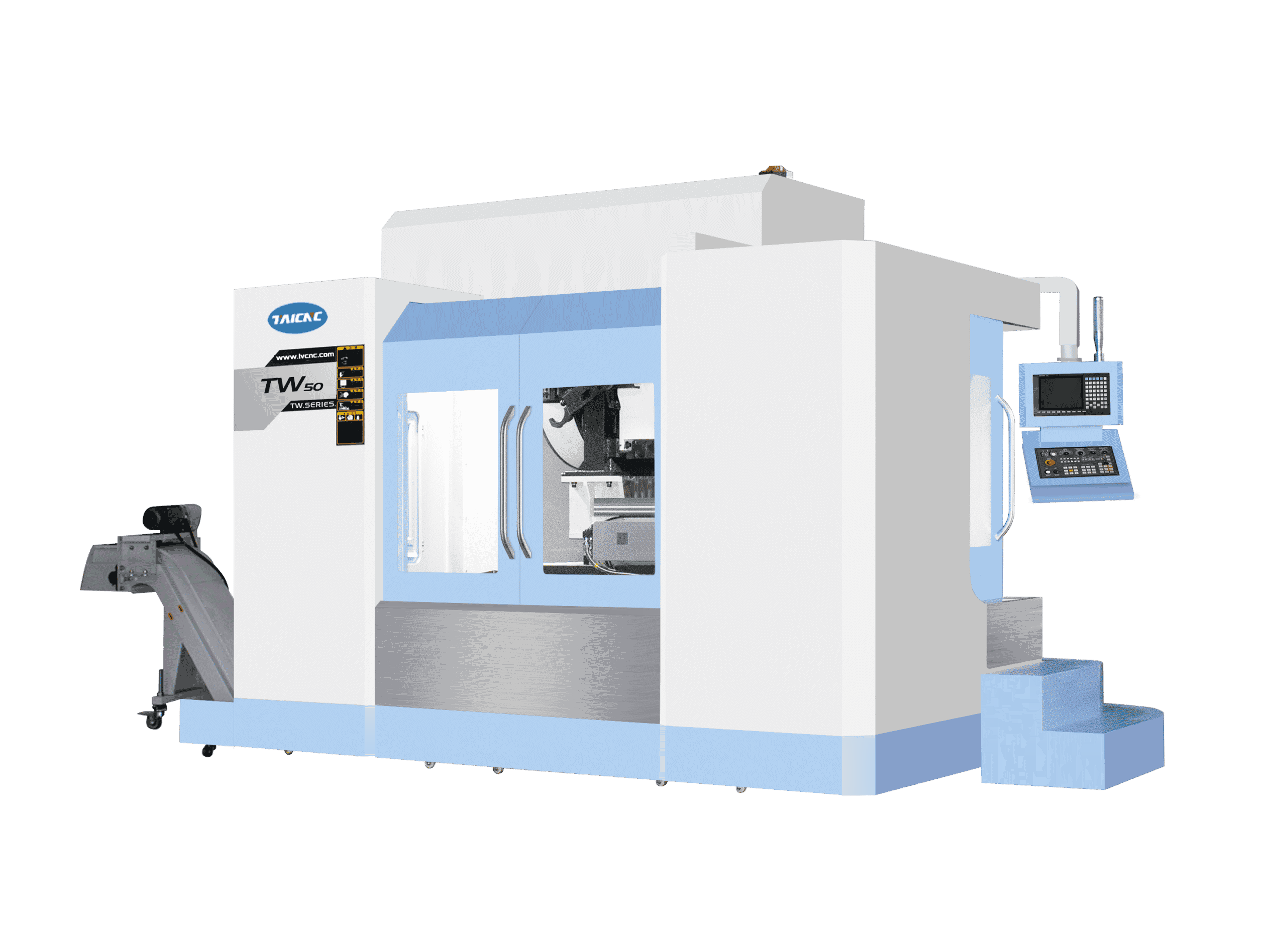

TAICNC TW series horizontal CNC milling machine is also called horizontal machining center or HMC machine. It is suitable for various fields, especially for the processing of box products. It can complete the processing of 4 surfaces in one clamping.

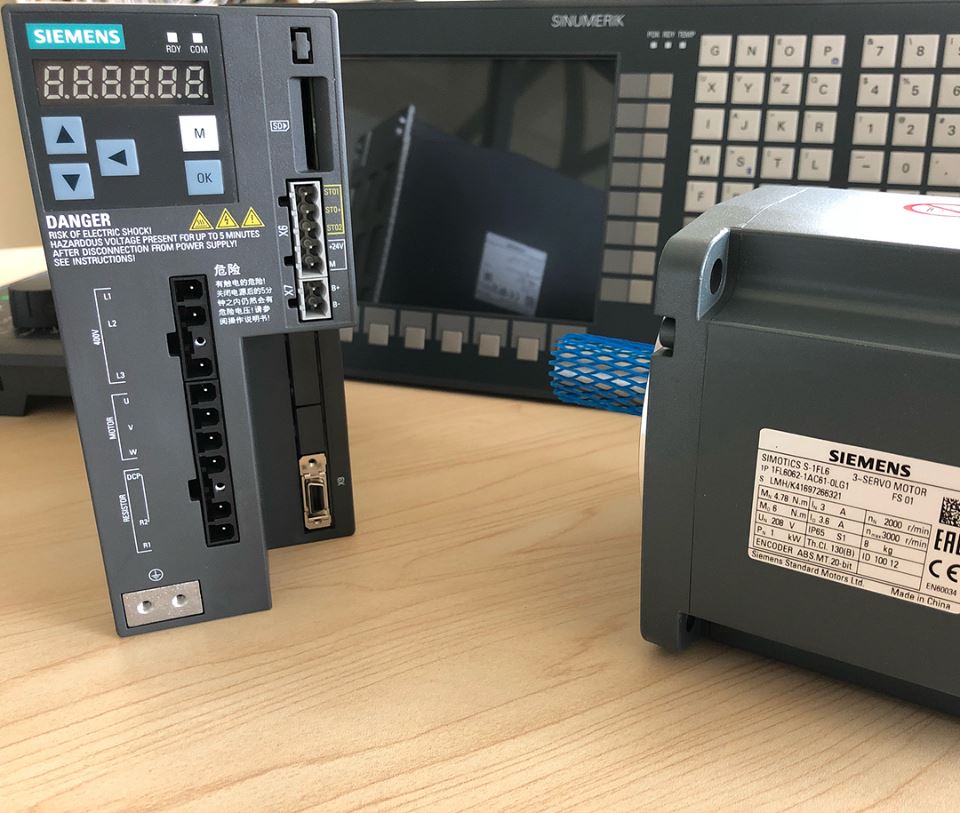

CNC controller is the brain of CNC milling machine. Our CNC milling machine is equipped with popular CNC controller, which is convenient for operators to use quickly and skillfully.

Including a variety of economical CNC controllers and high-end CNC controllers, they all have excellent performance and can meet the needs of your machine tools in actual work.

Our CNC milling machine are designed according to international standards and delivered to customers with guaranteed quality and perfect after-sales service.

A CNC milling machine is not a simple machine, and the manufacture of a qualified CNC milling machine requires the support of a large number of suppliers.

TAICNC has established a good cooperative relationship with many well-known suppliers around the world, and we can get their quick response in the supply chain, so that we can quickly deliver CNC milling machines to customers. And we store a large number of spare parts, so we can quickly respond and solve the problem when something fails and needs to be replaced.

Do you know CNC milling machine?

CNC milling machine is a metal processing CNC machine

It consists of Computer numerical control machine tools referred to as CNC.

In business, CNC milling machine is the most widely used CNC machine

It also has another name we call it a machining center.

However, there are some differences in the titles between different countries.

CNC milling machines are used for manufacturing operations like cutting, drilling, reaming, boring, milling and grinding. The machined parts can be made from metal, wood or plastic.

Our life has benefited from the emergence of CNC milling machines.

It is a precision CNC machine tool.

The aerospace industry, the medical industry, and the electronics industry can all benefit from CNC milling products.

CNC milling cutters perform processes like drilling and cutting parts with incredible precision, so there is no room for human error.

The process is an increasingly popular industrial solution as it can be adapted to detailed sizes and shapes of various materials.

If you are still using manual milling machines, I think you should pay attention to CNC milling machines. Compared with manual milling machines, it has advantages in processing accuracy, processing efficiency, and error rate, but it is more expensive than manual milling machines.

There are many types of CNC milling machines, which can be divided into the following according to the form of motion:

These are the two forms of exercise we see most often. Among them, the vertical CNC milling machine has the following types:

This is mainly distinguished according to the usage scenarios of CNC vertical milling machines.

According to the number of motion axes, it can be divided into:

A CNC milling machine is a special machine that uses computer numerical control (CNC) to control the movement of its cutting tools.

This kind of machine is used for shaping and cutting a wide range of materials, including wood, plastic, and metal. The machine is controlled by a computer program that tells it what to do. For example, if you want to cut out a shape from wood or plastic, you’ll need to write a program that tells the machine where to move its cutting tool.

To use a CNC milling machine, you need to know how to program in G-code language.

Or you need to know how to use MasterCam. A program to export the created graphics as G code.

Through the program you can manufacture products of any shape with a CNC milling machine.

CNC vertical milling machines are the most common CNC milling machines.

CNC vertical milling machines are exceptionally versatile and are used across all industries, making them the most widely used CNC machines in the world.

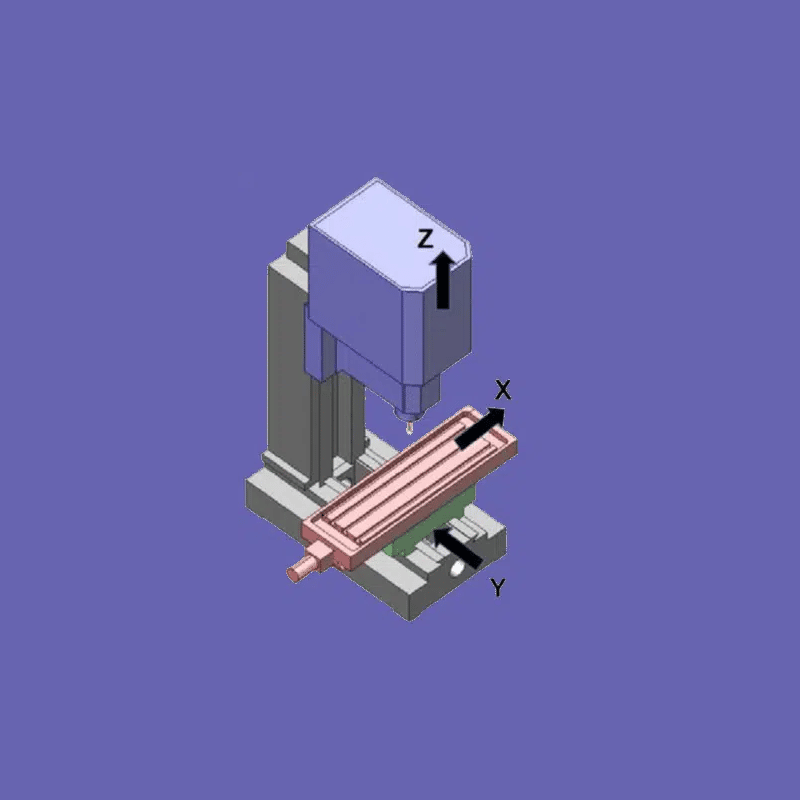

CNC vertical milling machines have a vertical structure with a vertical spindle (the axis of rotation of the cutting tool).

The cutter is mounted vertically and the workpiece is cut from the top. For applications requiring extensive top surface machining.

At present, the most commonly used CNC vertical milling machine is a three-axis machining center, which performs three-axis machining based on X, Y and Z axes, and can be divided into table-driven and spindle-driven.

Horizontal CNC milling machine is also called horizontal machining center.

Unlike the CNC vertical milling machine, the spindle of the horizontal CNC milling machine moves downward horizontally.

A Horizontal CNC milling machine is a machine that uses a rotary table to perform precision work and is able to cut, drill, or mill parts and other materials.

It has a spindle that holds the rotating tool and can move it in all directions. The machine also has a chuck or collet to hold the part being machined. The headstock holds the spindle and moves it in all directions.

The worktable on a horizontal CNC milling machine can be rotated horizontally while the piece being machined remains stationary. This allows you to make cuts at any angle on the workpiece without having to change its position or rotate it manually by hand.

Our most common CNC milling machine is the 3 axis CNC milling machine, which has the highest market share.

A 3 axis CNC milling machine is actually also called a 3 axis machining center.

It consists of three motion axes X, Y, Z.

Among them, the X and Y axes are for horizontal movement, and the Z axis is for up and down movement.

3 axis milling evolved from the practice of rotary filing, and is a milling process that operated on two axes, the X & Y axis.

In 3 axis machining, the workpiece remains still while the cutting tool moves along the three axes to mill the part.

3 axis machining still one of the most widely used techniques to create mechanical parts, and can be used for automatic/interactive operation, milling slots, drilling holes, and cutting sharp edges.

4 axis CNC milling machine is developed on the basis of 3 axis CNC milling machine.

In fact, the 4 axis CNC milling machine is just a rotary table added to the table of the 3 axis CNC milling machine.

If you only bought a 3 axis CNC milling machine in the early stage, you can also purchase a rotary table to realize the function of 4 axis simultaneous processing.

The 4 axis CNC milling machine can realize the machining of multiple faces of the part in one clamping.

This kind of processing method improves the processing efficiency and reduces the error, which is the choice of many customers.

This adds a rotation about the X-axis, called the A-axis.

The spindle has 3 linear axes of movement (X-Y-Z), like in 3-axis machining, plus the A-axis occurs by rotation of the workpiece.

There are a few different arrangements for 4 axis machines, but typically they are of the ‘vertical machining’ type, where the spindle rotates about the Z axis.

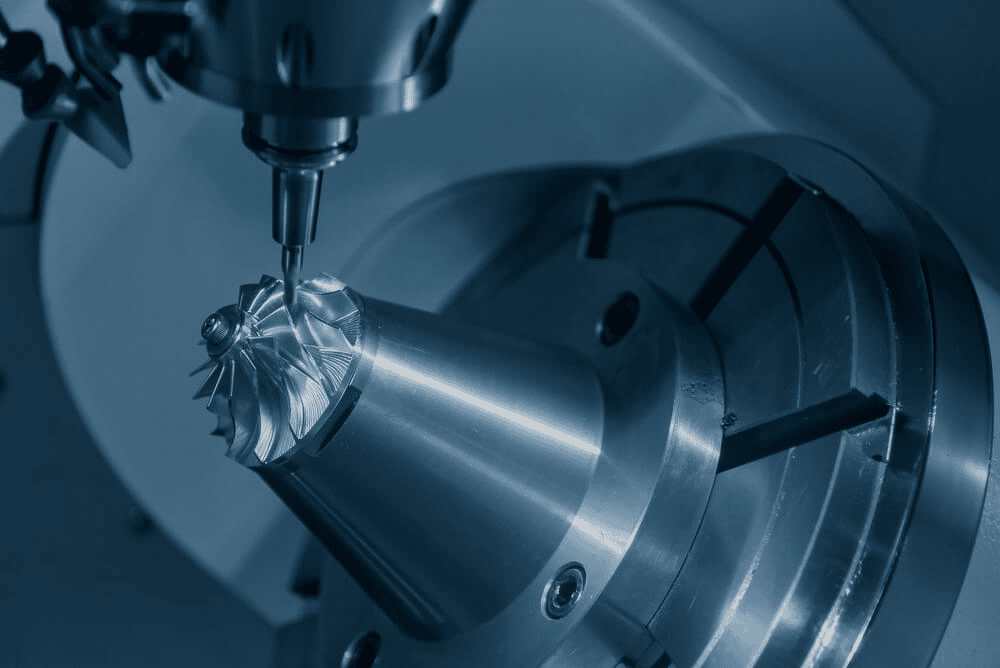

5 axis CNC milling machine is also called 5-axis machining center, it is the most precise CNC machine manufactured so far.

A 5 axis machining center is an industrial machine that can perform five types of motion and make one part from the result.

It has five axes: X, Y, Z, A and B. The axes are used to manufacture a product in the most efficient manner.

The main purpose is to build complex parts in less time and with greater accuracy and repeatability. The machine’s functions include roughing, finishing, drilling and tapping threads.

There are many types of 5 axis CNC milling machines, as follows:

A 5 axis CNC machine has two extra rotary axes which opens the door to an infinite number of machining possibilities.

The types of rotary axis include rotary axes A, B and C which rotates around the X-axis, Y-axis, and Z-axis respectively.

While these are three extra axes and not two, they’re still considered 5 axes in total.

The combination of the additional axes is machine dependent and can come in any combinations of AB, AC or BC.

We all know that CNC milling machine is the most widely used CNC machine at present.

You will find that a CNC mill has many benefits over a manual mill.

Cost-effectiveness

CNC milling machine can bring you more efficient processing efficiency, you don’t need to equip each milling machine with a worker like manual milling machine.

One worker can operate multiple CNC milling machines at the same time. The high efficiency of CNC milling makes it more profitable.

Mass production

Proficient in CNC milling, you can customize various fixtures for your CNC milling machine to achieve batch processing of parts.

High precision

CNC milling machine is controlled by CNC controller, equipped with servo motor, precision screw and guide rail drive.

Controlled by the program, this enables the CNC milling machine to produce the parts with the least error, and you can get higher precision.

Complex processing

CNC milling machines can realize the processing of multiple surfaces in one clamping, such as 4 axis CNC milling machines and 5 axis CNC milling machines.

The advent of 5 axis CNC milling machines has opened the door to infinite machining possibilities.

A 5 axis CNC milling machine is necessary in the processing of complex parts, such as impellers, which are.

CNC milling machine is not a simple machine, it consists of many core components. If you don’t know it, please read on and let’s disassemble it together.

The frame is the foundation of the CNC milling machine, on which the core components of the CNC milling machine are installed.

Different types of CNC milling machine frames are different.

For example, the frame of a CNC vertical milling machine is composed of a column and a base, while the armor of a CNC double-column milling machine is composed of a gantry and a base.

Even the frame of some CNC milling machines is integral.

This is the core component that supports the movement of the CNC milling machine, and its quality directly affects the stability and machining accuracy of the CNC milling machine.

Screws and guides are very difficult to manufacture because they have to be protected from damage and wear over a long period of time.

Therefore, most CNC milling machine manufacturers purchase from suppliers.

Currently, mainstream screw and guide rail suppliers include HIWIN, PMI, THK, Rexroth, etc.

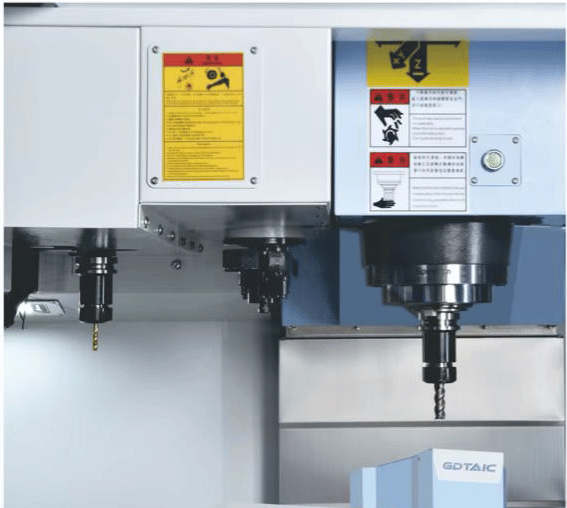

The spindle is the most important part of the CNC milling machine.

All machining tasks are done by the spindle rotation.

There are many types of spindles, which are distinguished according to the transmission form as follows:

Different types of spindles correspond to different processing scenarios.

For example, direct-coupled spindles and electric spindles are suitable for high-speed machining and geared spindles are suitable for heavy milling.

The spindle also has different taper holes, such as BT, BBT, HSK, etc.

Automatic tool changer is very important.

Although not required, it is helpful to improve processing efficiency.

It can avoid the need for frequent tool replacement in the actual machining process. Thereby improving the machining efficiency of CNC milling machine.

There are many types of automatic tool changer, as follows:

Different types of ATC have differences in the number of stored tools and the speed of changing tools. Among them, the umbrella type is the slowest, and this method is also being abandoned.

CNC controller is the brain of CNC milling machine.

It controls all the movements of the CNC milling machine.

Different brands of CNC controllers have a great influence on the accuracy of surface gloss.

Servo motors and drivers for CNC milling machines are usually matched with CNC systems.

When people buy CNC milling machines, they will choose the CNC system they are proficient in using.

Currently mainstream CNC system manufacturers include FANUC, Siemens, Mitsubishi, Heidenhain, Rexroth, SYNTEC.

The CNC milling machine spindle will generate a lot of heat during high-speed operation, which requires a cooling system to cool it.

Otherwise, long-term over-temperature operation will cause damage to the spindle.

The cooling system usually has air cooling, water cooling and oil cooling.

Cooling the spindle by injecting coolant/oil into it is currently the most mainstream cooling method.

Each axis of CNC milling machine will move continuously during work.

This requires the support of the lubrication system.

The lubrication system is to provide continuous lubrication for these movements to reduce the wear of the screw and guide rail.

The lubrication system will work intermittently according to the set time.

CNC milling machines will continuously produce iron filings during the machining process.

This requires the support of the chip conveyor so that the iron filings can be discharged quickly.

Although not necessary, this can improve processing efficiency and does not require workers to constantly deal with iron filings.

A CNC milling machine is not a cheap machine, it is an expensive piece of equipment.

Therefore, the price of CNC milling machine is a matter of concern to everyone.

There are many factors that affect the price of CNC milling machines, as follows:

Each of these factors affects the price of CNC milling machines.

If you want to buy CNC milling machine from China, below I give a price reference range. Hope this helps you.

The above prices are for reference only, if you are considering importing CNC milling machines from China, you may wish to contact us.

Maybe we can’t cooperate in the end, but we can give you some suggestions and some help.

A CNC milling machine is an expensive investment, and it’s especially important that we get the right CNC milling machine for us.

Most novices don’t know how to choose a CNC milling machine that suits them.

This largely depends on the following key considerations:

Knowing the above factors, I believe you already have the answer on how to choose the right CNC milling machine.

CNC milling machines are different from ordinary commodities, and they usually cannot be ordered directly on e-commerce websites such as Amazon or ebay.

You need to contact CNC milling machine manufacturers and suppliers.

Communicate many details with them.

Such as choosing your nearest suppliers and manufacturers, they will provide you with quotations.

All of TAICNC’s CNC milling machines come with a 1-year warranty.

In the event of a malfunction, our experts will respond immediately.

Provide you with technical guidance through video, telephone, etc.

If replacement parts are needed, we will send them by air as soon as possible, and arrive at your factory as quickly as possible. We have a large stock of all parts.

If you can’t solve it, we will let your local partner handle it.

Your page rank:

TAICNC is a famous CNC machine brand in the Chinese market. With experience in manufacturing field and strength of technical line, excellent team of engineers, skilled technical workers and rich customer partners in many fields, we are always in the leading position in service quality and price.

08:00 - 18:00 Whatsapp, Skype,WeChat

sales support

B66 Yanhe Rd, Zhangmutou, Dongguan