Are you interested in our CNC double column machining center?

If you are looking for a reliable CNC double column machining center then you are in the right place.

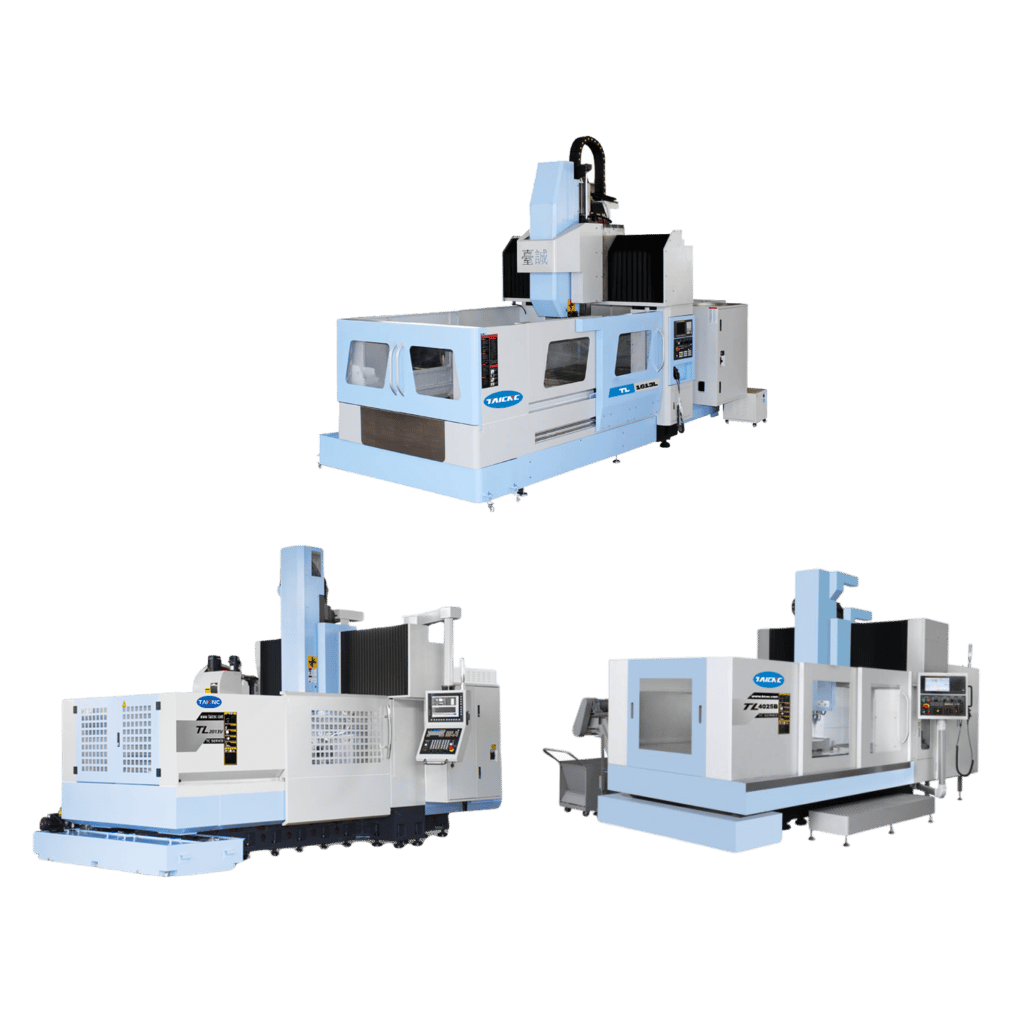

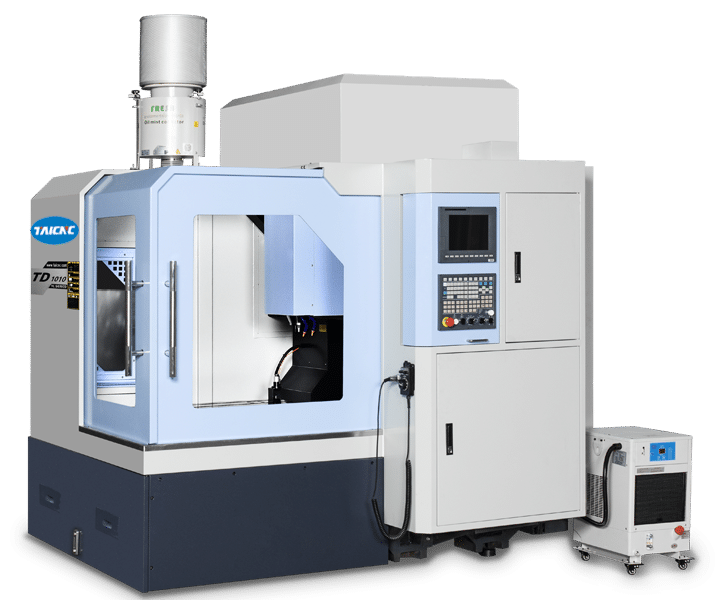

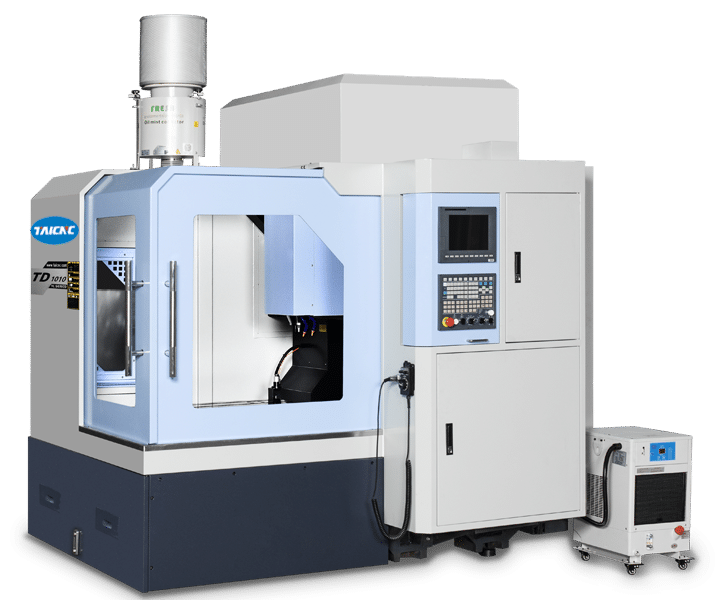

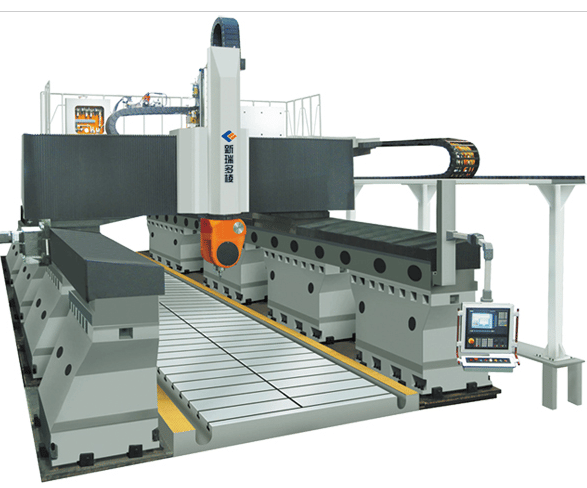

CNC double column machining center is also called CNC double column milling machine and CNC gantry machining center. It is also a kind of vertical machining center, TAICNC is a leading manufacturer and supplier of CNC double column machining center in China.

With more than 20 years of experience in CNC machine manufacturing, our double column machining centers are widely appreciated by customers worldwide. Whether you’re making large parts or molds, the CNC dual column machining Center is the answer and is currently on sale at manufacturer’s prices.

As a Chinese CNC double column machining center manufacturing expert, TAICNC has developed and designed a variety of doublecolumn machining center specifications, which can meet the processing needs of most parts.

Whether you need light milling or heavy milling, we have corresponding CNC machines, which are suitable for all kinds of product and mold manufacturing and have 4 axis and 5 axis options.

Selling CNC double column machining centers at manufacturer prices, here you can get exclusive offers from the best CNC double column machining center suppliers in China.

A double column machining center is an expensive piece of equipment, if you have any questions about it please contact us for expert answers.

Are you interested in our CNC double column machining center?

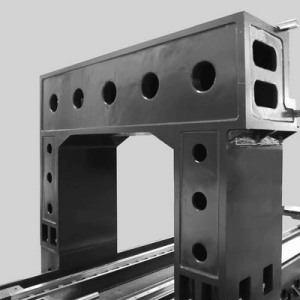

TAICNC is a manufacturing expert of CNC double column machining centers, and each double column machining center is made of high-quality casting materials.

In the design, the actual processing needs are fully considered, and the best structural design is adopted to improve the precision and stability of the CNC machine tool.

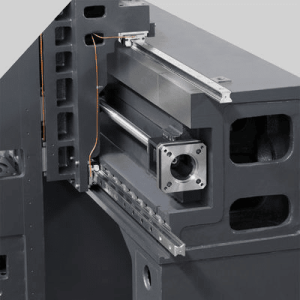

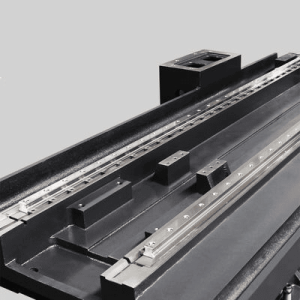

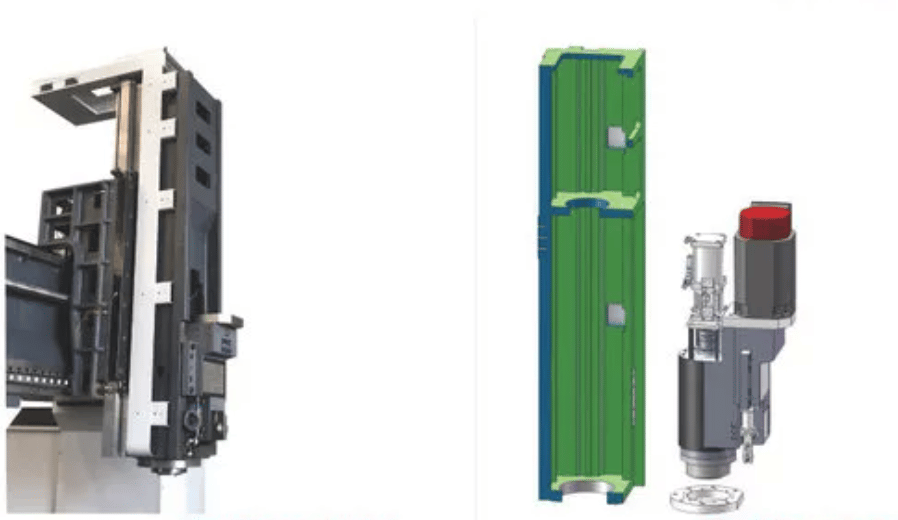

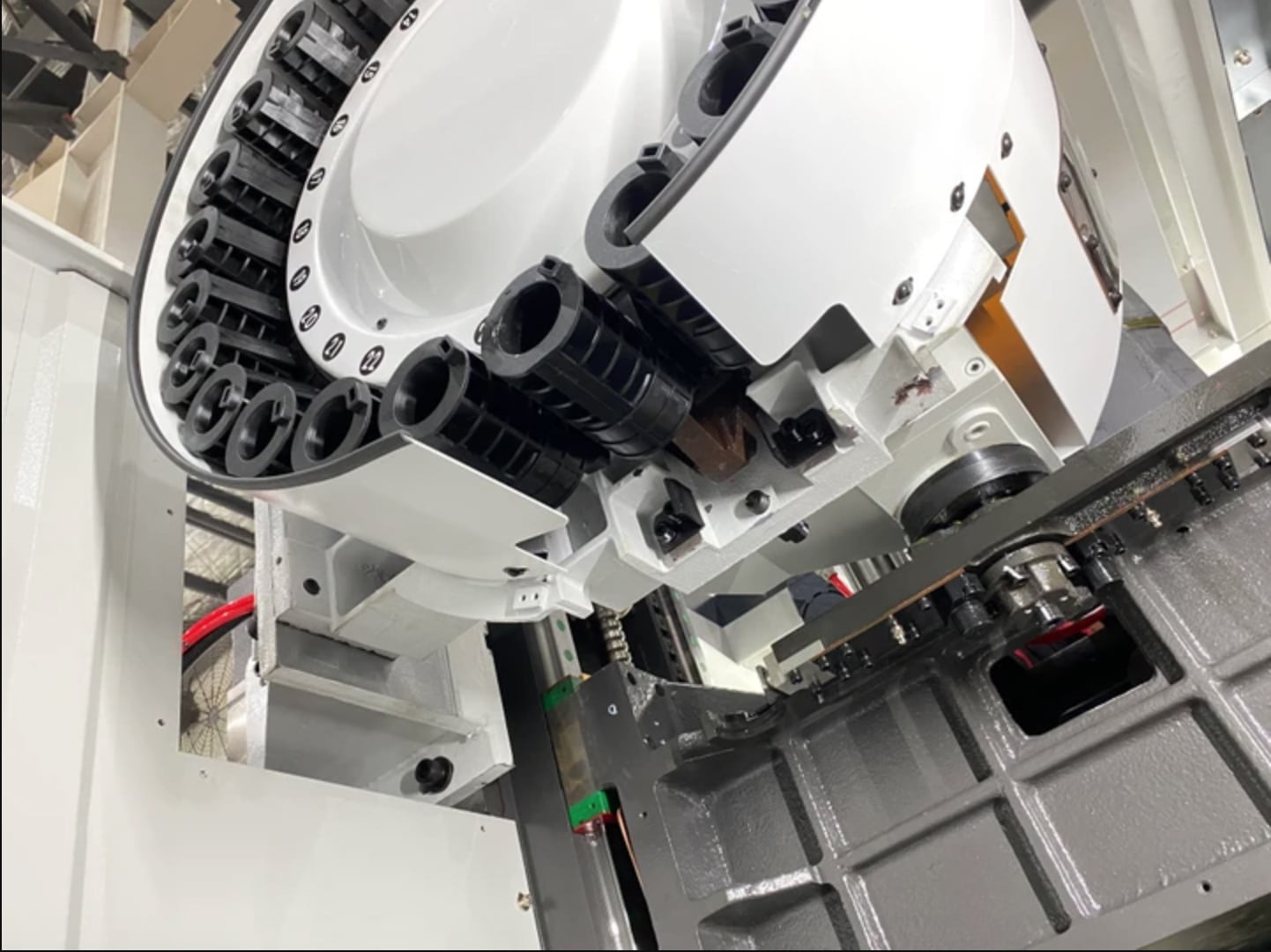

Our double column machining centers use the best core components currently on the market, including screw rods, guide rails, bearings, etc. We have established a good cooperative relationship with many well-known suppliers, providing a variety of options for customers to choose from.

Our CNC double column machining center are designed according to international standards and delivered to customers with guaranteed quality and perfect after-sales service.

A CNC double column machining center is not a cheap machine, it is a long-term investment. Building a good CNC two-column machining center requires the support of multiple suppliers around the world. We have established long-term and stable cooperative relations with many excellent suppliers, so that we can quickly deliver CNC machines to customers for use.

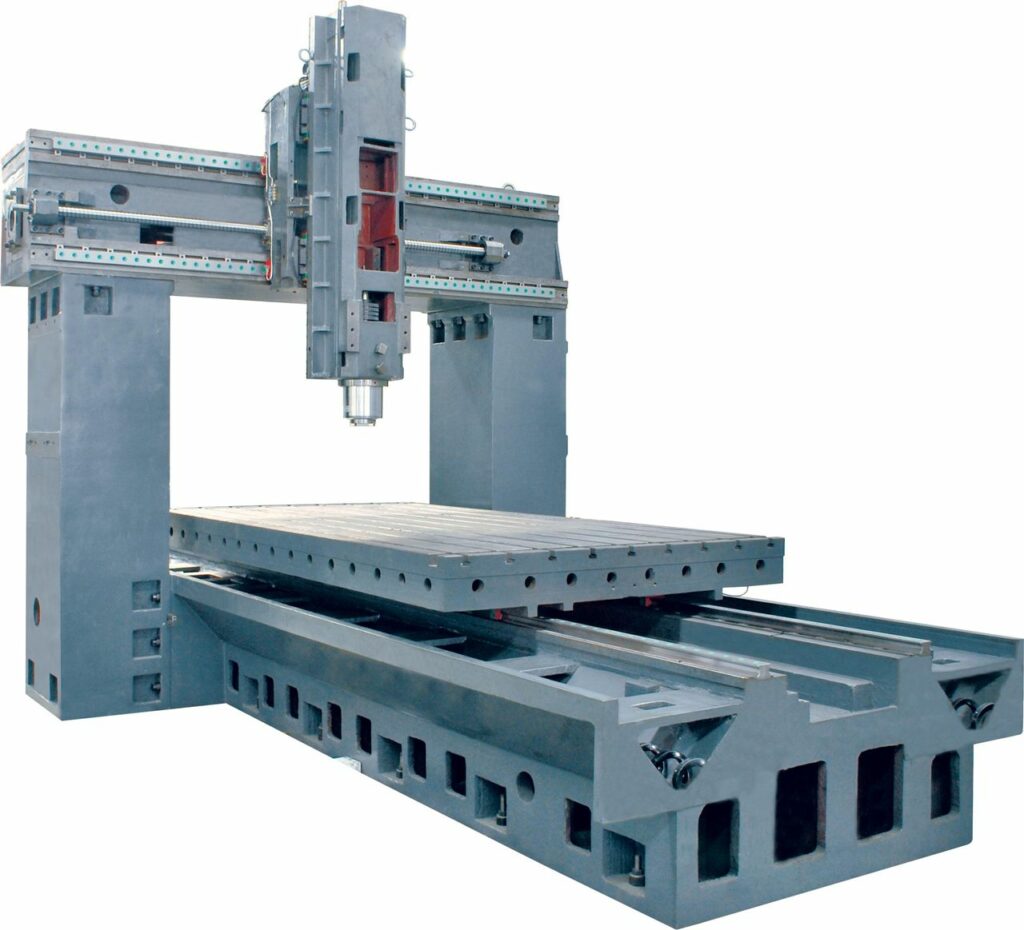

CNC double column machining center, also called double column CNC milling machine, gantry machining center, double column vertical machining center, is one of the largest CNC machines available.

Its overall structure is a large machining center with double columns and top beam forming a portal structure frame.

There is a cross beam in the middle of the double columns. It is especially suitable for machining large workpieces and workpieces with complex shapes.

Double column machining center is a kind of vertical machining center, which is suitable for any industry and can be expanded with 4 or 5 axes.

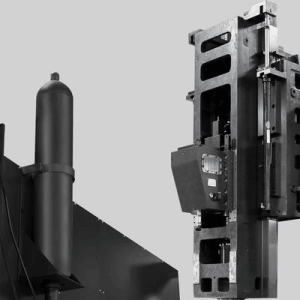

Usually CNC double column machining center consists of X, Y, Z three axes, its structure and vertical machining center for the spindle vertical downward movement.

There are several types of CNC double column machining centers according to the structure as follows:

Multiple types of gantry machining centers in the above composite forms. The processing characteristics, capabilities, and product processing applications are not exactly the same.

According to the number of axes can be divided into the following types:

Double column machining centers work in the same way as vertical machining centers.

Its main function is milling.

In practice, vertical machining centers are unable to machine large parts and molds due to size limitations.

The double column machining center breaks this limitation.

By writing the program in G code and importing it into CNC controller, the part is placed on the table, and the double column machining center realizes the manufacturing of parts and molds by moving the X, Y and Z axes and rotating the spindle.

Double column machining center can also be equipped with a rotary table to achieve 4 axis or 5 axis machining.

Double column machining centers are large machines, designed for machining large parts.

It is mainly used in heavy industries, such as aircraft, automobile, ship and other heavy industries.

Mainly processing large and complex shape of the workpiece, such as processing the aircraft beam, frame and some parts of the large machinery.

In a word, double column machining center is a large machine tool designed for processing large and complex parts, which is suitable for various industries, especially for large parts industry.

Fixed beam type double column machining center is the most common double column machining center in the market.

Its structure is simple and easy to understand, mainly consists of table, bed, column, beam, saddle, ram and other components.

The table moves left and right on the bed as X axis, the ram and saddle move forward and backward along the guide rail as Y axis, and the ram moves up and down along the vertical direction as Z axis.

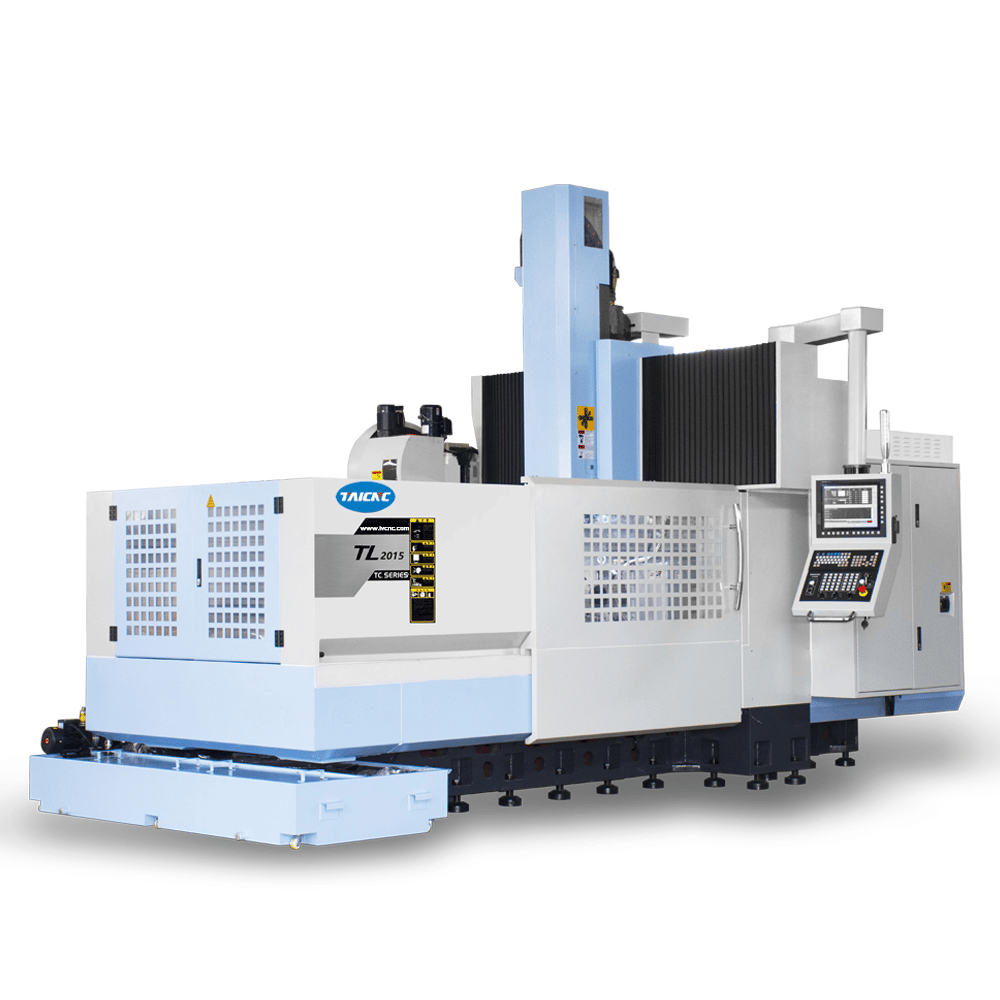

Moving beam type double column machining center is also common in the market, and its structure is more complicated than fixed beam type gantry machining center.

It also consists of bed, table, column, beam, saddle, ram and other mechanical parts.

The table is rectangular in the bed to do left and right movement for the X axis, crossrail segment up and down movement for the Z axis, ram and saddle along the crossrail horizontal direction back and forth movement for the Y axis.

The moving beam type double column machining center is suitable for machining higher height parts.

The structure of moving column type double column machining center is more complicated, rare in the market and expensive.

The two columns of this double column machining center are movable, the two columns move to the left and right at the same time for X axis, its table is fixed, the ram and saddle move forward and backward along the horizontal direction of the beam guide for Y axis, and the ram on the saddle moves up and down along the vertical direction for Z-axis.

The machining center where the table is fixed and the cross beam moves on two overhead bridges is the bridge type double column machining center.

Some people think that bridge type double column machining center is a kind of moving beam double column machining center, which is not a correct understanding.

The moving beam gantry refers to the structure where the crossbeams move on the columns. In fact, the bridge type gantry machining center is an upgrade of the moving column type gantry machining center.

If you have never used a CNC double column machining center before, you will find the following benefits when you use it for the first time:

Double column machining center is a must for large products, but of course it is expensive.

There are many types and specifications of CNC double column machining centers, and the price varies greatly between different types and specifications.

There are many factors that affect the price of a double column machining center, as follows.

All these factors are closely related to the price of double column machining center.

If you want to buy a CNC double column machining center in China, I can give you an approximate price range, as follows:

The above only lists the price range of 3 axis, 4 axis and 5 axis double column machining center, the price varies greatly due to different specifications.

In addition, the price of moving beam type, moving column type, bridge type double column machining center is more different. The price of different types of double column machining centers may vary by $50,000.

A two-column machining center is a long-term and expensive investment.

How to choose the right double-column machining center?

This is a good question.

We have summarized some key considerations on how to choose the right vertical machining center as follows.

I believe that after understanding the above questions, you should have an answer for how to choose the right double-column machining center.

Your page rank:

TAICNC is a famous CNC machine brand in the Chinese market. With experience in manufacturing field and strength of technical line, excellent team of engineers, skilled technical workers and rich customer partners in many fields, we are always in the leading position in service quality and price.

08:00 - 18:00 Whatsapp, Skype,WeChat

sales support

B66 Yanhe Rd, Zhangmutou, Dongguan