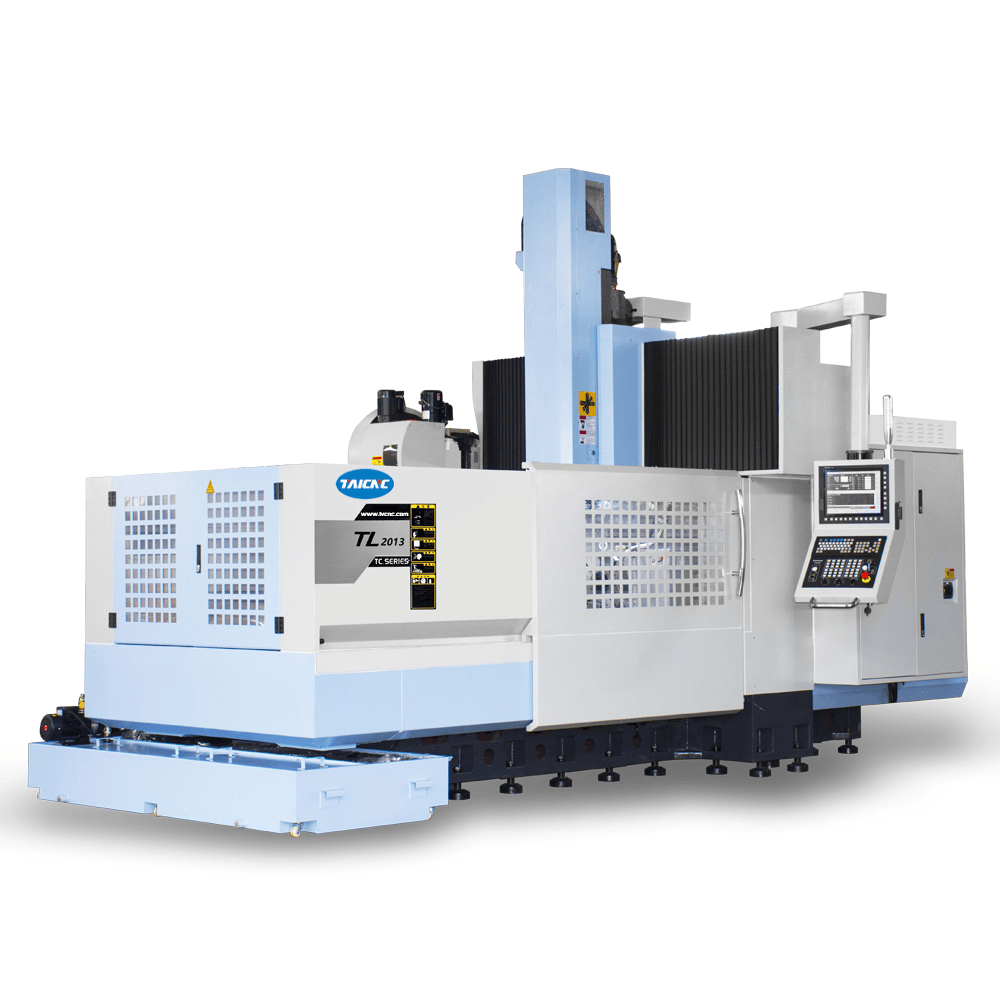

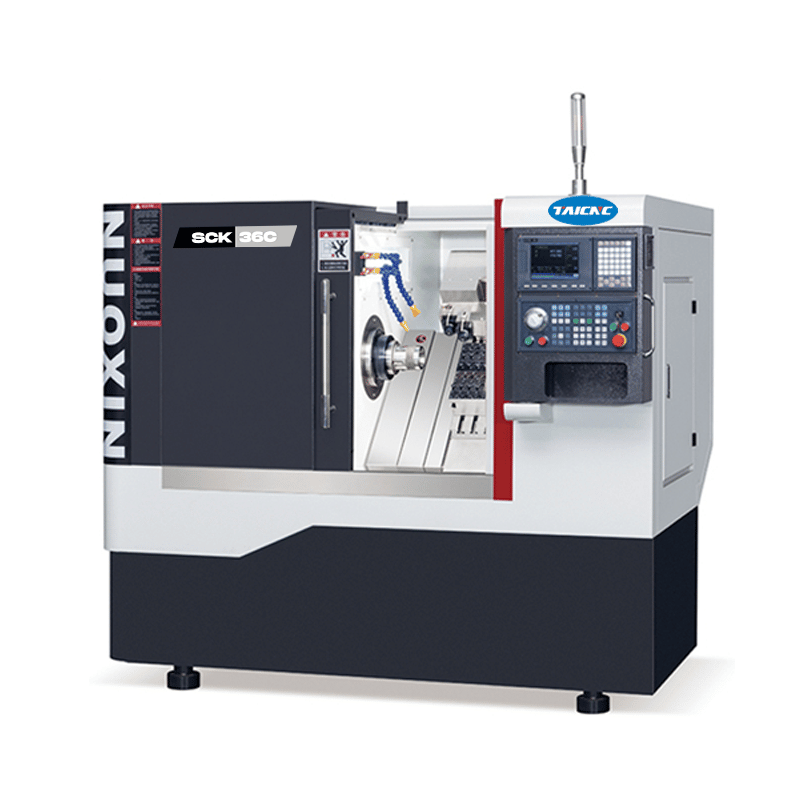

SCK-36C Slant Bed Turning and Milling CNC Machine is a row knife CNC lathe, which has the function of milling at the same time.

The major parts are manufactured from high-quality Meehanite cast iron and are tempered to relieve stress.

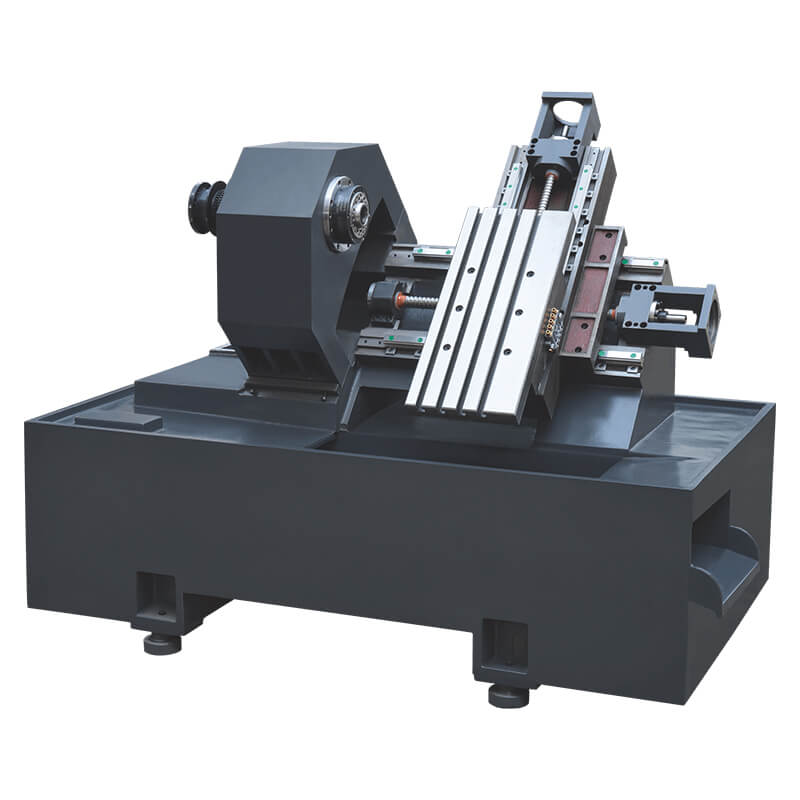

The ruggedly constructed base is scientifically rib reinforced for maximum stability during turning.

Extra wide box ways on the X and Z axes way surfaces are hardened and precision ground.

The 45 slant bed design features extremely firm support for the turret and added chip removal efficiency.

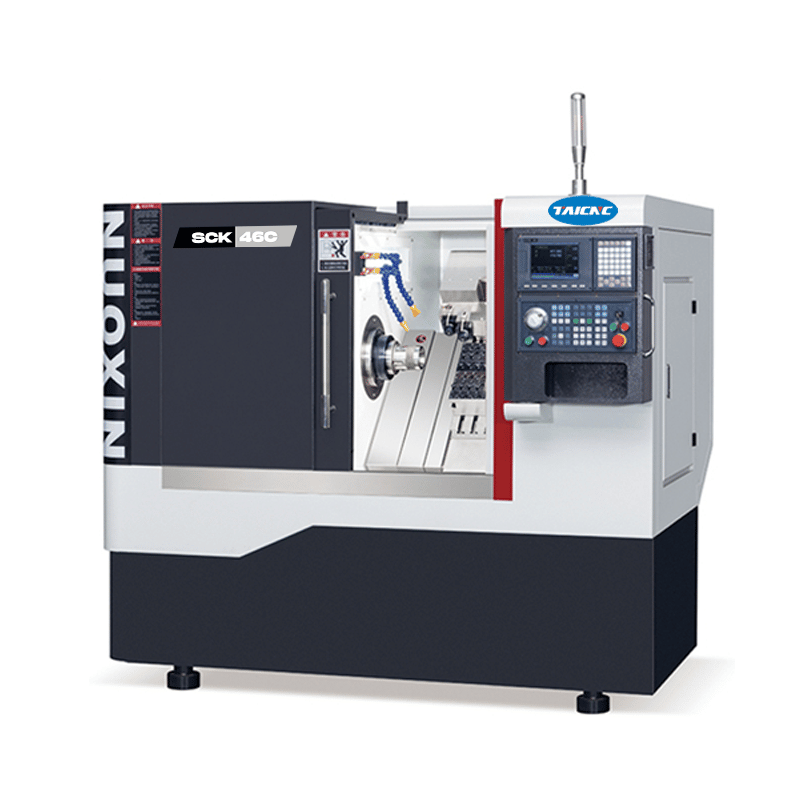

In addition, we have several other models to choose from. Please look down for details.

The bed tilts 30 °or 45 °, adopts high quality cast iron resin sand moulding, tight reinforcement plate structure, good rigidity and strong shock resistance.

The X-axis is directly connected by servo motor and precision pre-stretch ball screw through elastic coupling and adopts high rigidity and high precision linear slide rail. It is equipped with a computer automatic lubrication system to lubricate linear guideway and ball screw.

The positioning accuracy is high, the thermal deformation is small, and the moving speed can reach 30M/min.

The utility model adopts the hydraulic or servo rotating turret of eight working stations in Taiwan, the tool is changed quickly, the tool is changed nearby, and the tool changing time is 0.3 to 0.5 seconds, which is suitable for heavy load cutting.

Slant Bed Turning and Milling CNC Machine video

SCK series Slant Bed Turning and Milling CNC Machine is a high-speed precision CNC machine developed by TAICNC.

It uses a 2-axis linear guideway structure, it has both turning and milling functions, the following is a demonstration video of Slant Bed Turning and Milling CNC Machine.

Same type of product

There are several models of SCK series CNC lathes to choose from, you can visit our catalogue to see more models of CNC lathes.

Structural Design

All structural parts are manufactured from high quality stress relieved Meehanite cast iron, to minimize deformation.

Massive base construction ensures high rigidity and excellent vibration dampening.

Features box ways on X, Z axis. All surfaces are hardened and precision ground.

Box-way

With oversized box-ways on both ensures maximum stability and efficiency even under heavy cutting loads. All box-ways are precision ground and heat treated for an optimal surface finish.

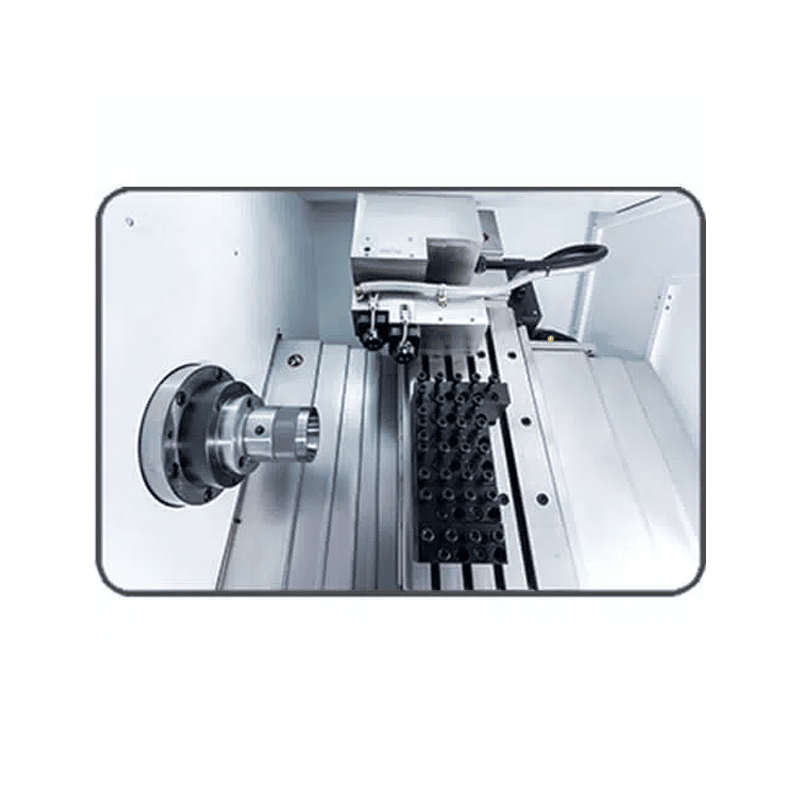

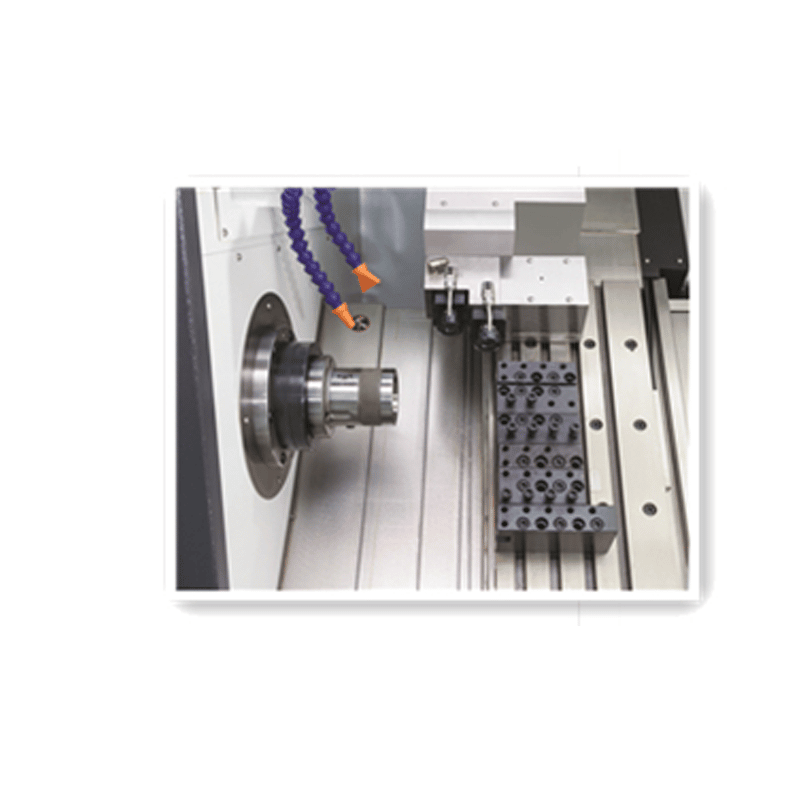

Row knife structure

Row knife, automatic tool changer in CNC turning center, very economical, suitable for processing small products including various materials.

And equipped with two ER25 power heads, which can realize the function of turning and milling.

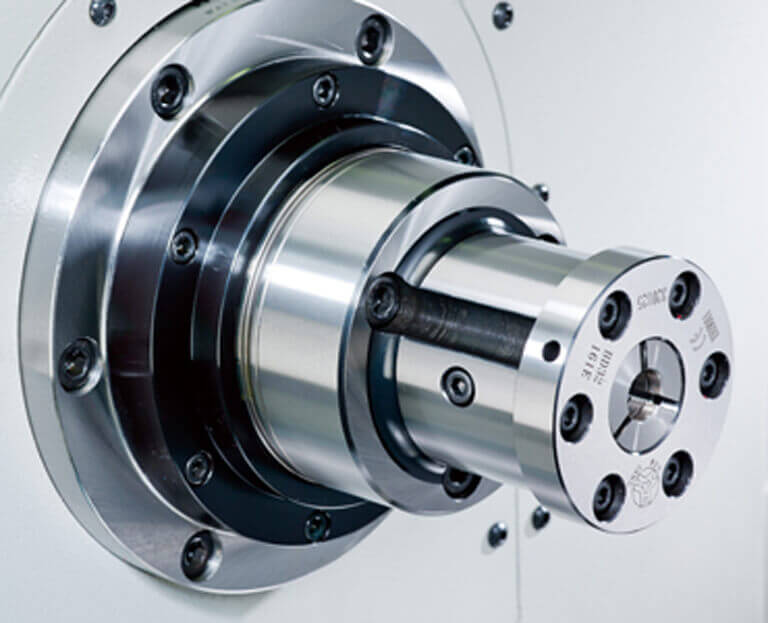

High speed spindle

Slant bed CNC lathe Machine Features a high precision spindle that accommodates both collet chucks and 3-jaw hydraulic chucks for versatile machining options. The spindle features a double row of roller bearings combined with angular contact ball bearings that resist radial and axial loads. With spindle speeds up to 4000rpm, fast and efficient machining is guaranteed, as well as very fine workpiece finishing.

High precision roller screw

precision roller screw with is a very important part of Slant bed CNC lathe. It affects the accuracy of machine tools. This machine uses C3 grade high precision ball screw with pre-extension process, improve the transmission rigidity and machine accuracy.

Precisions ballscrews are made through a grinding process of the screw spindle. Precision ground ballscrews provide high positioning accuracy and repeatability, smooth movement and long service life. These highly efficient ballscrews are a perfect solution for a variety of applications.

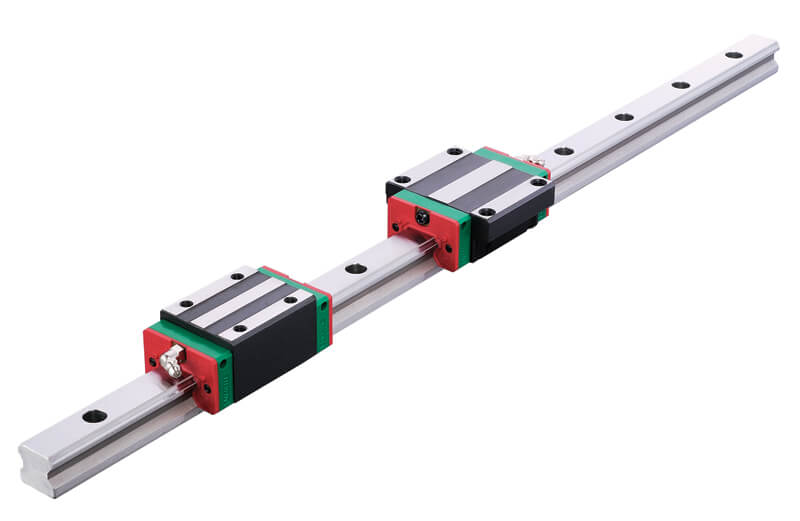

Precision linear guide

The CNC turning center of SCK series inclined bed adopts the structure of 2-axis linear guideway, which has the characteristics of high speed, high precision and so on. It is very suitable for the machining of precision products.

The HG series linear guideways are designed with load capacity and rigidity higher than other similar products with circular-arc groove and structure optimization. It features equal load ratings in the radial, reverse radial and lateral directions, and self-aligning to absorb installation-error. Thus, the HG series linear guideways can achieve a long life with high speed, high accuracy and smooth linear motion.

Chip Conveyor (Optional accessories)

A chip conveyor can be attached for automatic removal of excess chips. Either a screw type or a chain type conveyor can be used.

Best precision protective cover

The CNC lathe cover is used to protect the CNC turning center guide. It can protect the internal hard guide of the CNC lathe, the linear guide and the ball screw or the transmission rack from external corrosion and damage.

Precision Lathe Spindle Belt Driven

TAICNC each spindle has gone through 13 strict steps, four process tests, two dynamic balance tests to ensure that each spindle can play a high-precision operation stability.

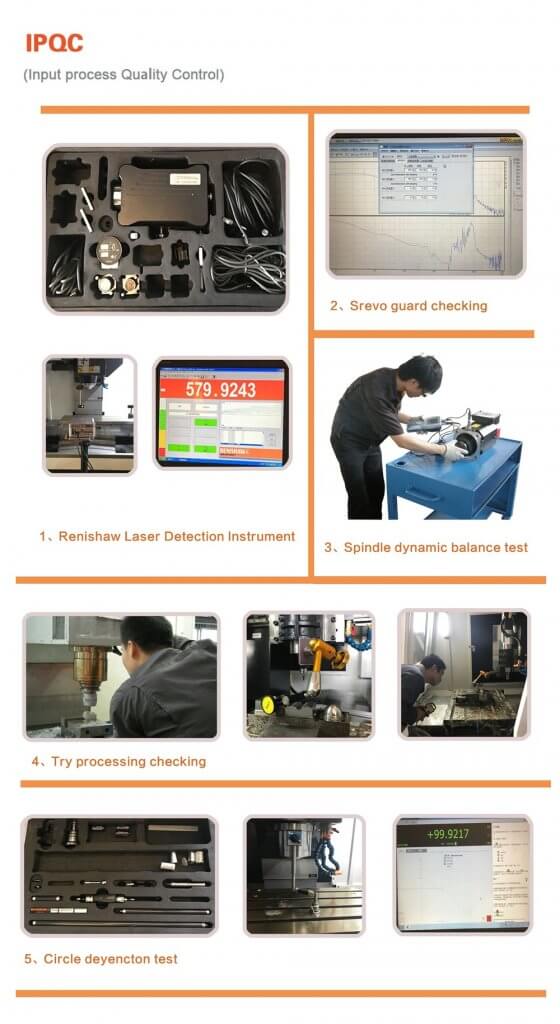

Quality management

Every machine tool produced by TAICNC is produced in strict accordance with the ISO standard. During this process, a variety of quality management tests will be carried out. We must ensure that all the CNC machine tools delivered to our customers are qualified and perfect.

A sophisticated laser unit is employed to inspect the three-axis accuracy.Including linear positioning, positioning, accuracy, pitch error, and backlash, etc.

use a ball bar tester is employed for inspecting servo accuracy, static and dynamic geometric errors.

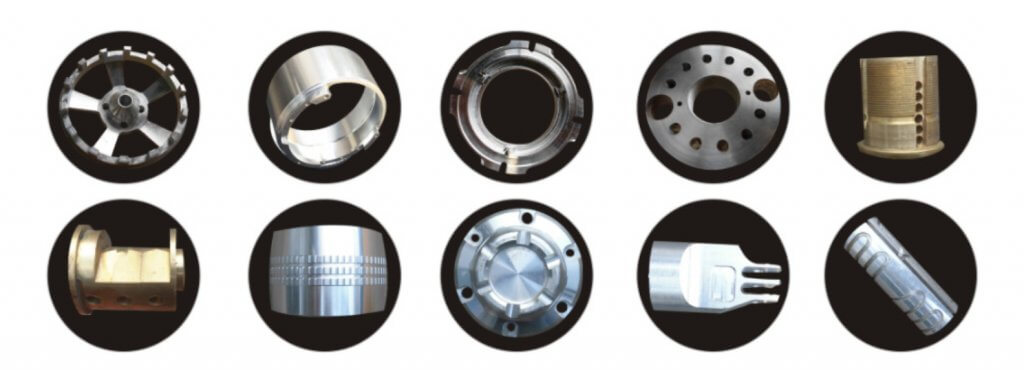

Production sample

CNC lathe can do a lot of work this is only part of it, it can process a lot of materials such as copper, aluminum, steel, Bakelite and so on, can be used in various fields, if you are not sure Whether to meet your requirements welcome to contact us.

About packaging and shipping

We use strict packaging for all machine tools to ensure that it will not be damaged during transportation. We have good cooperation with many transportation companies. We must ensure that the machine can be transported safely and on time to your factory.

TAICNC certificate

TAICNC has passed the ISO9001 / 14001 certification and CE certification, obtained a number of national patents, and strictly comply with manufacturing standards.

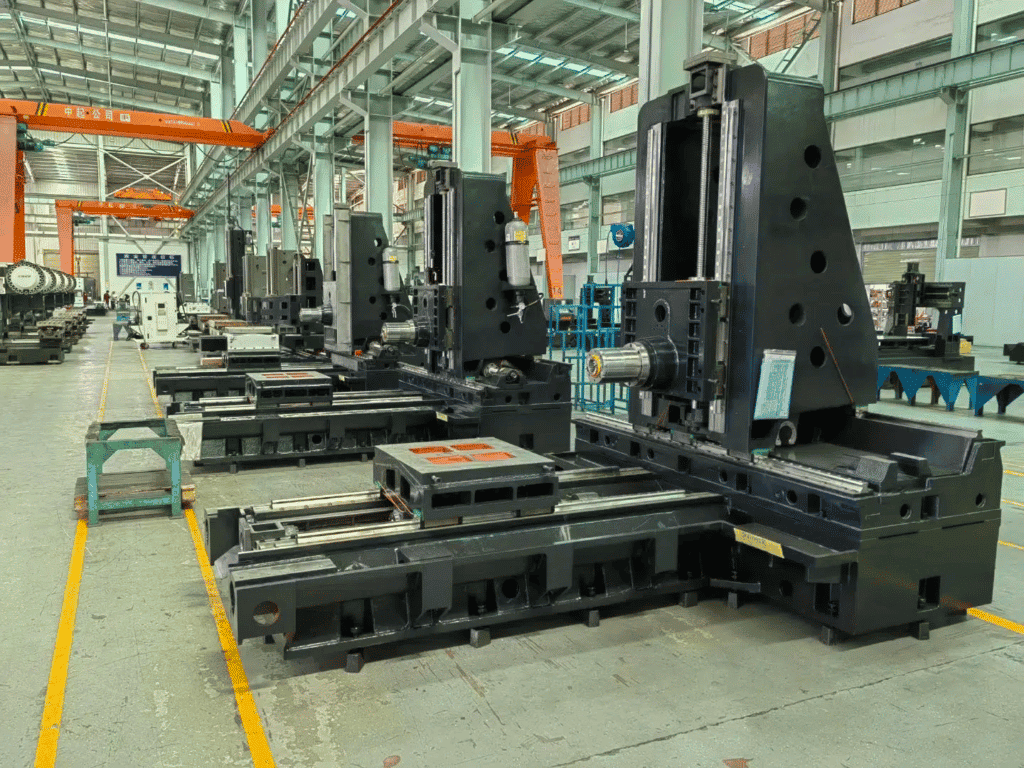

TAICNC manufacturing factory show

We have a sound management system and a clean factory, which is the first condition to ensure product quality.