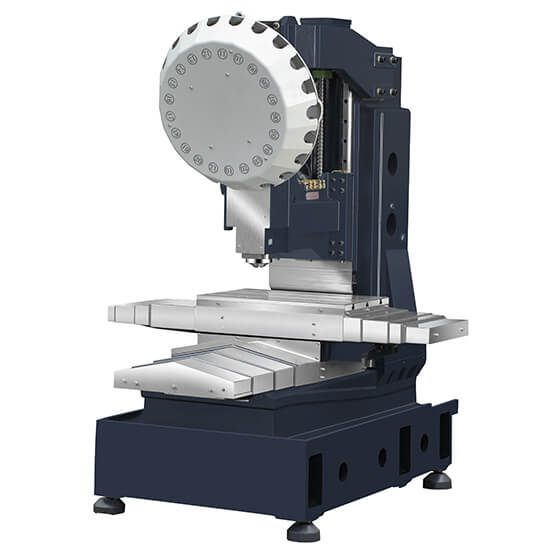

This small CNC mill adopts the same structural design as the CNC tapping center, which makes it very efficient. The spindle speed of the machine tool is 20, 000 RMP / min, and the spindle is made of large steel ball bearings.

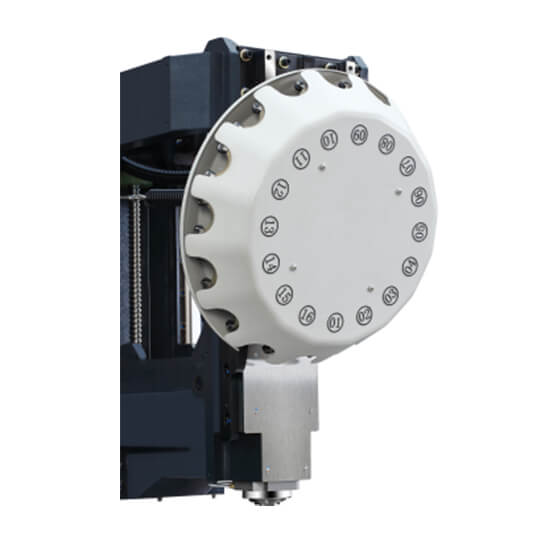

More suitable for high hardness milling workpiece, 3-axis 48M/min moving speed, very fast, equipped with 16-bit high-speed automatic tool changer, tool change time is 1 second, and can be expanded to 4-axis machining center or 5-axis machining center.

The maximum 15000rpm/min speed of the spindle can be selected.

5 axis small CNC milling machine video

Best casting material

TAICNC CNC machine tool The main structural parts are made of high-quality Meehanite cast iron (HT300A +), hardened to above HB190, and tempered to relieve stress.

All castings have a natural aging of 3-6 months, completely eliminating internal stress and ensuring the best stability of machine tool accuracy.

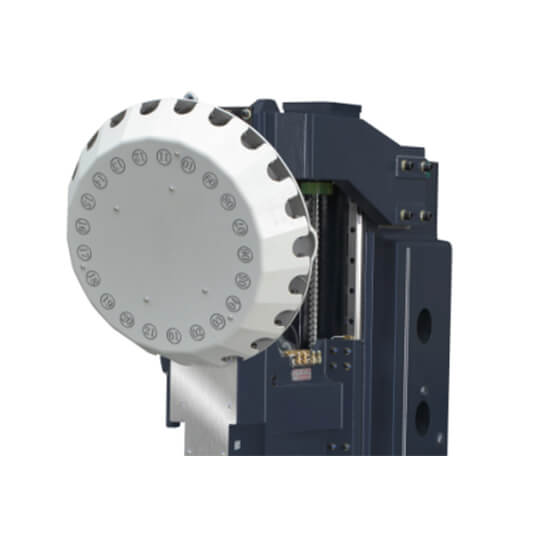

High-intensity head design

This small CNC mill uses the best head design to improve the overall performance of the machine. It is equipped with a high-speed automatic tool changer for efficient machining.

Large span column design

The large-span column design is more capable of improving the stability of the machine tool and reducing vibration during machining. Box structure large span A type column with high rigidity to ensure stability during machining.

Thickened honeycomb fuselage structure

This CNC small milling machine has a thickened honeycomb fuselage with 4 support legs, reducing distortion.

Weight, this structural design makes the base more stable in the actual production process to reduce machine tool vibration.

Highly rigid spindle head

The spindle head is a very important part of CNC tapping center, its rigidity and strength directly affect the machining quality of the machine tool. The spindle head of this small CNC milling machine adopts box structure to design, to increase cutting rigidity, improve the machining efficiency.

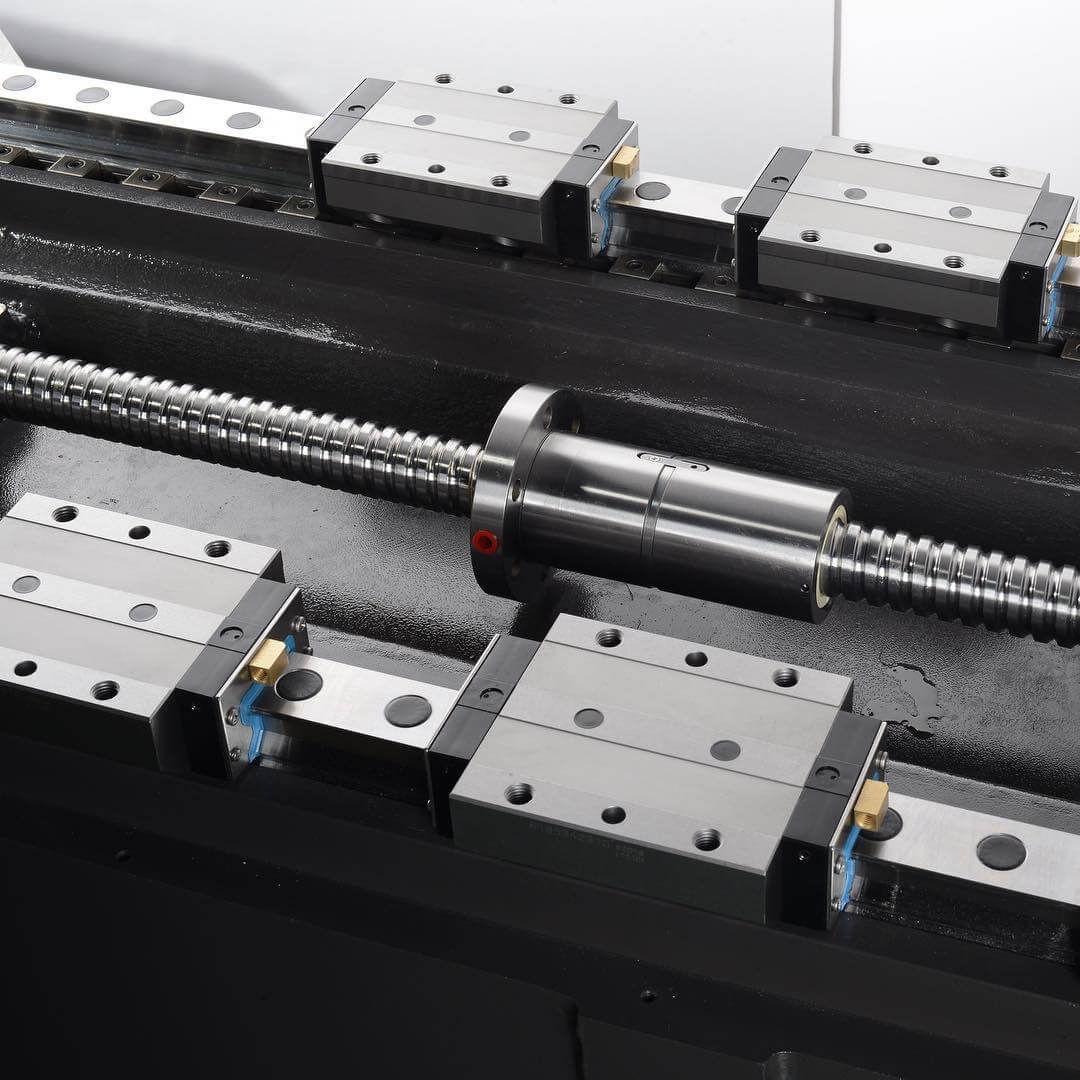

High-speed linear guide

All of 3 axes are equipped with high-precision ball-type linear guideways and ball screw, 3 axes rapid traverse speed can reach 48m / min, linear guides using current mainstream brands such as Taiwan HIWIN or German Rexroth.

Best precision roller screw

Ball screw with is a very important part of Small CNC milling machine. It affects the accuracy of machine tools. This machine uses C3 grade high precision ball screw with pre-extension process, improve the transmission rigidity and machine accuracy.

Best high-speed spindle

This machine uses a BT30 direct-coupled spindle with a maximum speed of 12,000 rpm. Its speed is very fast, the machining precision is very high, the surface finish is very good, and it can also choose 20000rmp/min. This spindle adopts large steel ball bearing technology and can be used for high hardness milling.

Best high-speed spindle

The CNC Tapping Center needs constant tool change during the production process. This machine is equipped with a 16-position servo automatic tool changer. The fastest tool change speed is 1 second. You can select up to 20 automatic tool changers.

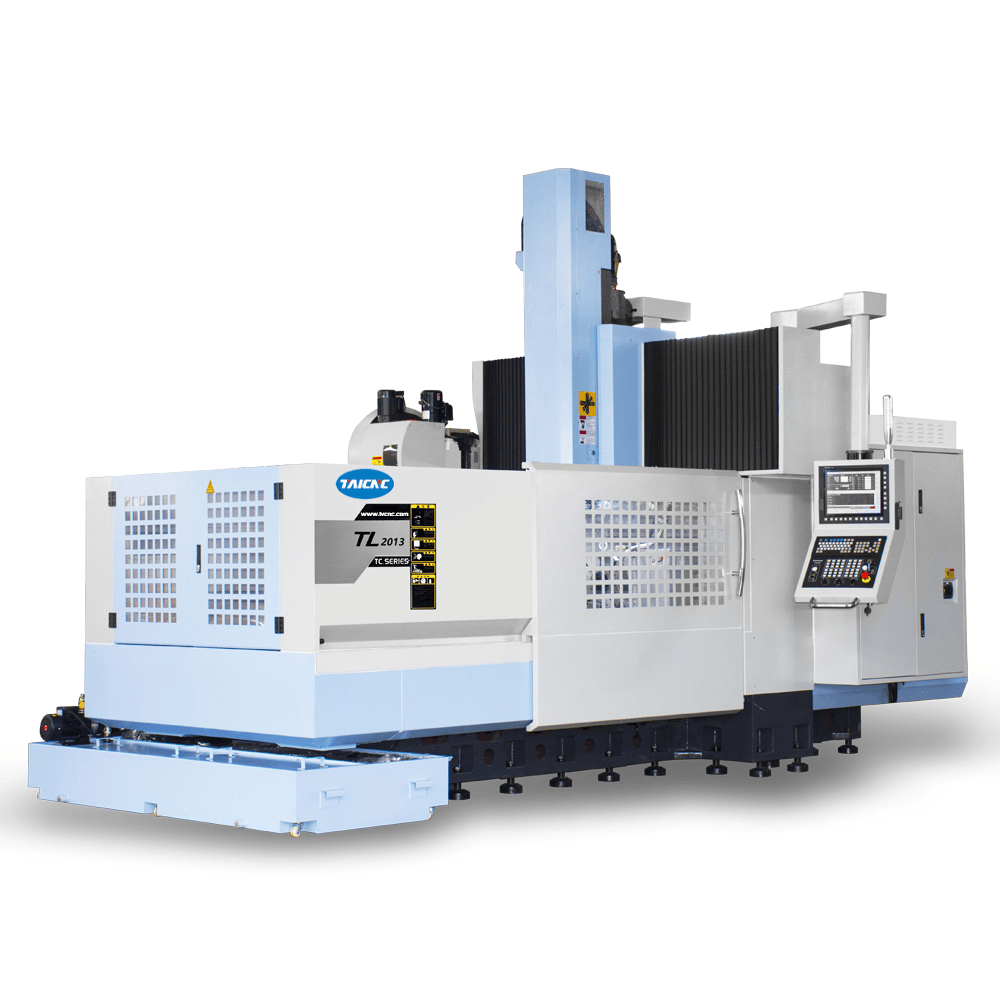

A number of well-known brands of CNC controllers can choose

The CNC controller is the brain of CNC Tapping Center. This CNC Tapping Center has four brands of CNC controllers to choose from. They are Taiwan SYNTEC/Germany Siemens/Japan Mitsubishi/Japan FANUC, and they all have rich experience in CNC controller manufacturing. , high market share, and provide complete technical manuals.

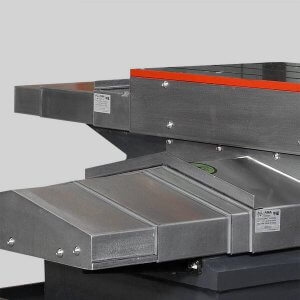

3 axis precision protective cover

CNC Tapping Center will continue to produce iron filings during the machining process, which will damage the machine. This CNC Tapping Center 3 shaft is equipped with a precision protective cover to prevent iron filings from damaging the machine during production.

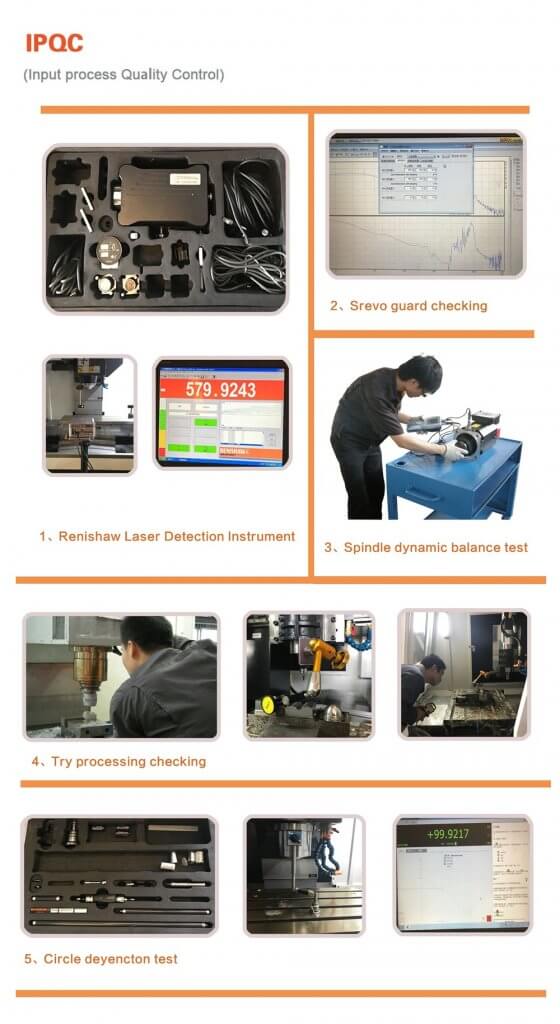

Quality management

Every machine tool produced by TAICNC is produced in strict accordance with the ISO standard. During this process, a variety of quality management tests will be carried out. We must ensure that all the CNC machine tools delivered to our customers are qualified and perfect.

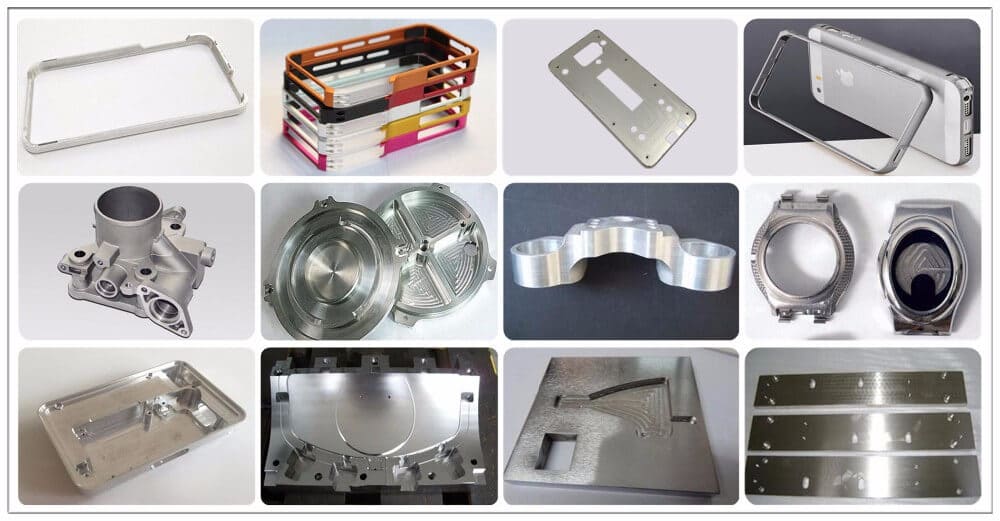

Production sample

The high-speed small CNC milling machine features high-speed rotation, fast, high-precision small hole machining and fast tool change. It can be applied to the processing of small plates, steel, disc-shaped parts and shells, widely used in 3C, aerospace, automotive, watches, electronics, small molds, medical equipment and other industries.

About packaging and shipping

We use strict packaging for all machine tools to ensure that it will not be damaged during transportation. We have good cooperation with many transportation companies. We must ensure that the machine can be transported safely and on time to your factory.

TAICNC certificate

TAICNC has passed the ISO9001 / 14001 certification and CE certification, obtained a number of national patents, and strictly comply with manufacturing standards.

TAICNC manufacturing factory show

We have a sound management system and a clean factory, which is the first condition to ensure product quality.