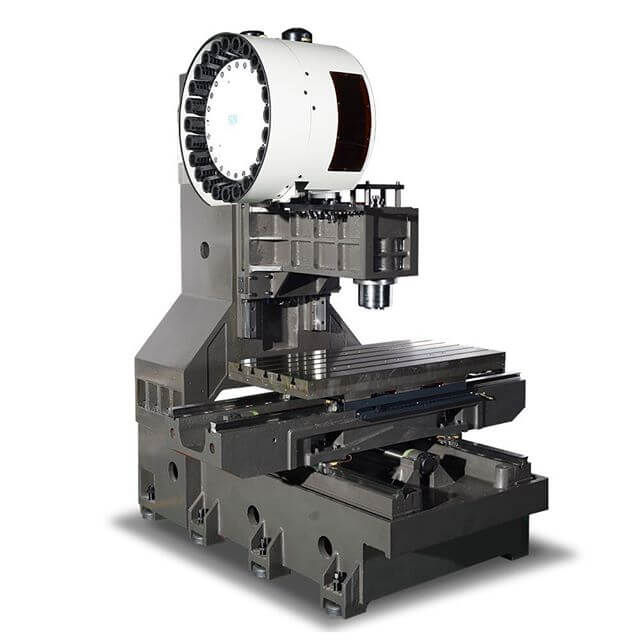

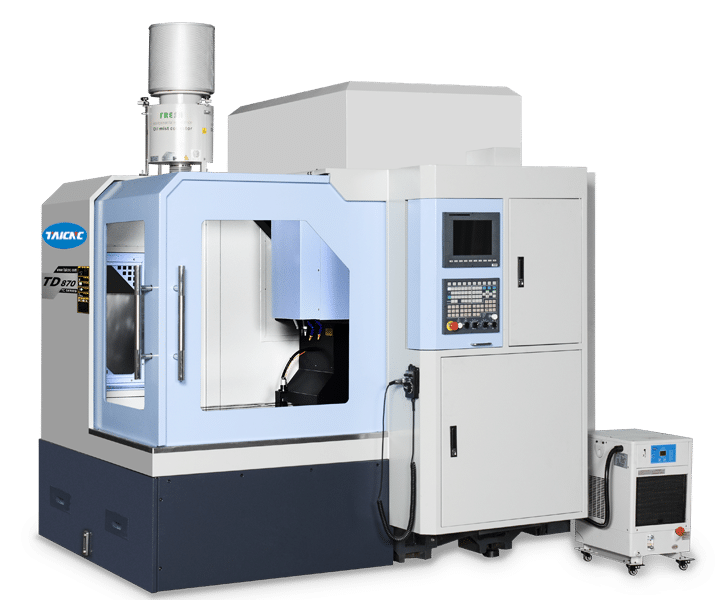

TC-855L vertical machining centers, also known as vertical CNC mill it is a very good CNC machine, equipped with high-rigidity belt spindle can be completed parts and mold work.

TC-855L CNC mill and machining center work video

The video demonstrates the use of the TC-855L machining center to complete the gearbox housing processing, which is done with 4 axes, also known as 4 axis machining center.

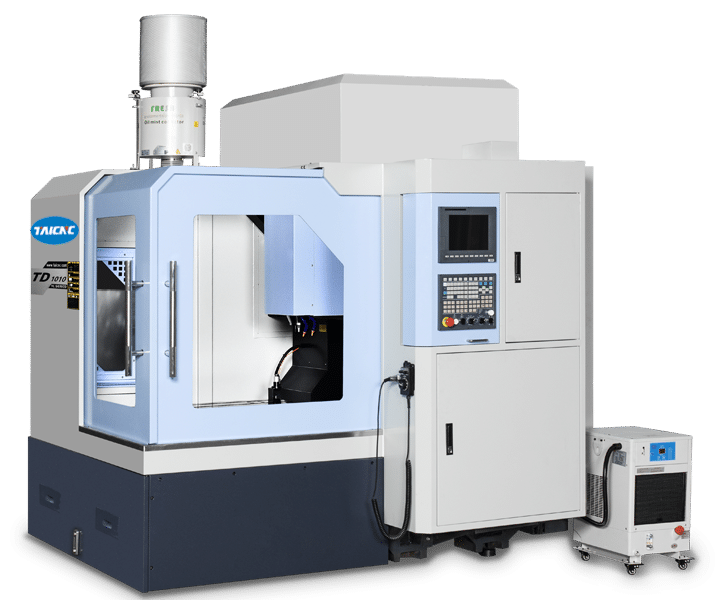

What is the difference between the TC-855 machining center and the TC-V8 machining center? The main difference is that the linear guide and the spindle speed are different.

Best casting material

TC-855L CNC machining center uses the best casting materials, major structural parts are manufactured from high quality Meehanite cast iron (GB 300+), tempered for stress relief with hardness over 190HB.

Good casting materials make the machine more robust and stable.

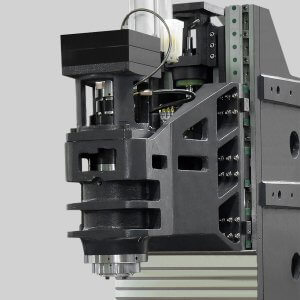

Best head design

The machining center head is a very important part. The TC-855L CNC Machining Center features a high-intensity head design. Reinforced transverse ribs increase bending and torsion resistance. Increased overall machining rigidity, It can complete the work of parts and molds.

Large span column design

The TC-855L CNC machining center features a long-span column design that increases machine stability and reduces vibration during machining. The box-shaped structure has a large span A-pillar with high rigidity to ensure stability during processing.

Thickened honeycomb fuselage structure

The vertical machining center has a thickened honeycomb fuselage with eight support legs, reducing distortion.

Weight, this structural design makes the base more stable in the actual production process to reduce machine tool vibration.

Highly rigid spindle head

The spindle head is a very important part of machining center, its rigidity and strength directly affect the machining quality of the machine tool. The spindle head of this CNC machining center adopts box structure to design, to increase cutting rigidity, improve the .

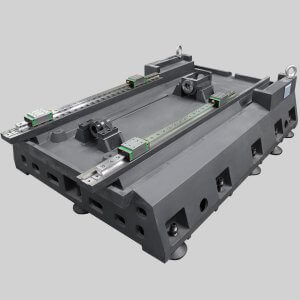

High-speed linear guide

This vertical machining center is equipped with a high-rigidity linear guide with a three-axis movement speed of up to 36/min. It is also compatible with high rigidity and high speed. The linear guide brands mainly use Taiwan HIWIN or Taiwan PMI, which are very good brands.The RG series features a roller as the rolling element instead of steel balls. The RG series is designed with a 45-degree angle of contact. Elastic deformation of the linear contact surface, during loading, is greatly reduced thereby offering greater rigidity and higher load capacities in all 4 load directions. The RG series linear guideway offers high performance for high-precision manufacturing and can achieve a longer service life than traditional ball bearing linear guideways.

High precision roller screw

Ball screw with is a very important part ofHigh speed machining center. It affects the accuracy of machine tools. This machine uses C3 grade high precision ball screw with pre-extension process, improve the transmission rigidity and machine accuracy.

precision ballscrews are made through a grinding process of the screw spindle. Precision ground ballscrews provide high positioning accuracy and repeatability, smooth movement and long service life. These highly efficient ballscrews are a perfect solution for a variety of applications.

High rigidity belt spindle

The TC-855L CNC machining center is equipped with a high-rigidity belt-type spindle with a maximum speed of 10,000 rpm/min. The belt-type spindle has better rigidity and is more suitable for rough machining of molds and parts.

High speed automatic tool changer

Vertical machining centers with high-speed automatic tool changers automatically change tools to make them more efficient. This high-speed machining center is equipped with a 24-bit automatic tool changer. The tool change speed is 2 seconds.

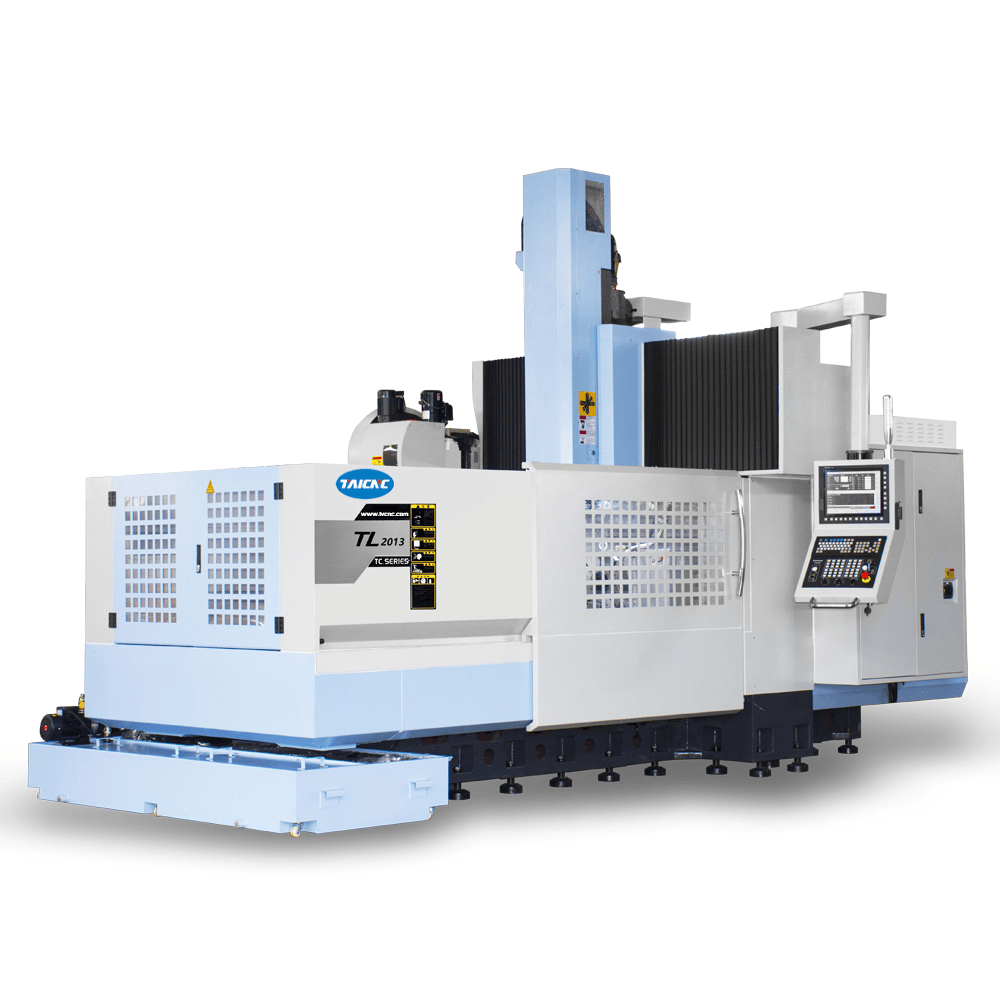

Equipped with well-known brand CNC controller

The CNC controller is the brain of CNC mill. This small CNC mill has four brands of CNC controllers to choose from. They are Taiwan SYNTEC/Germany Siemens/Japan Mitsubishi/Japan FANUC, and they all have rich experience in CNC controller manufacturing. , high market share, and provide complete technical manuals.

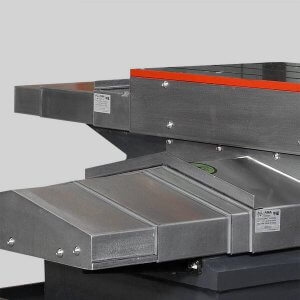

3 axis precision protective cover

High speed machining center will continue to produce iron filings during the machining process, which will damage the machine. This High speed machining center 3 shaft is equipped with a precision protective cover to prevent iron filings from damaging the machine during production.

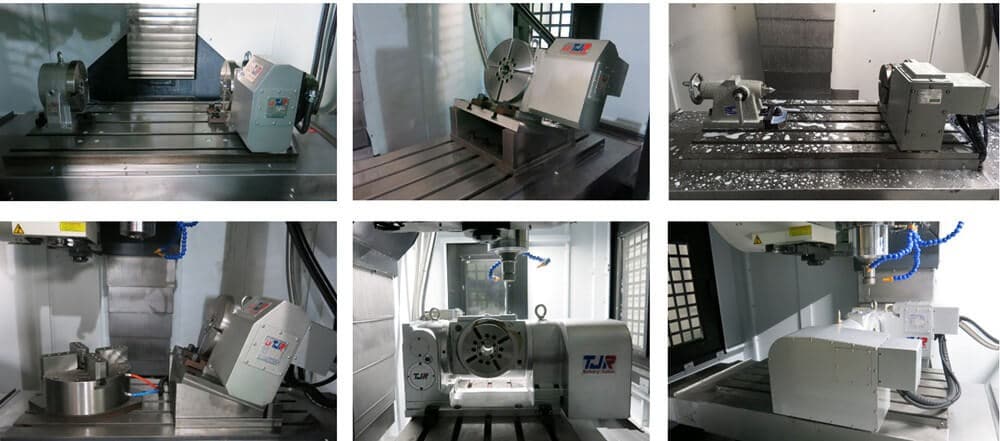

Multi-axis linkage can choose

CNC machining center can choose the CNC rotary table to realize the functions of 4 axes and 5 axes, which makes it have higher processing efficiency. All the processes can be completed in one clamping, but it is not necessarily required for each workpiece. Specific, choose according to the products you need to manufacture.

Quality management

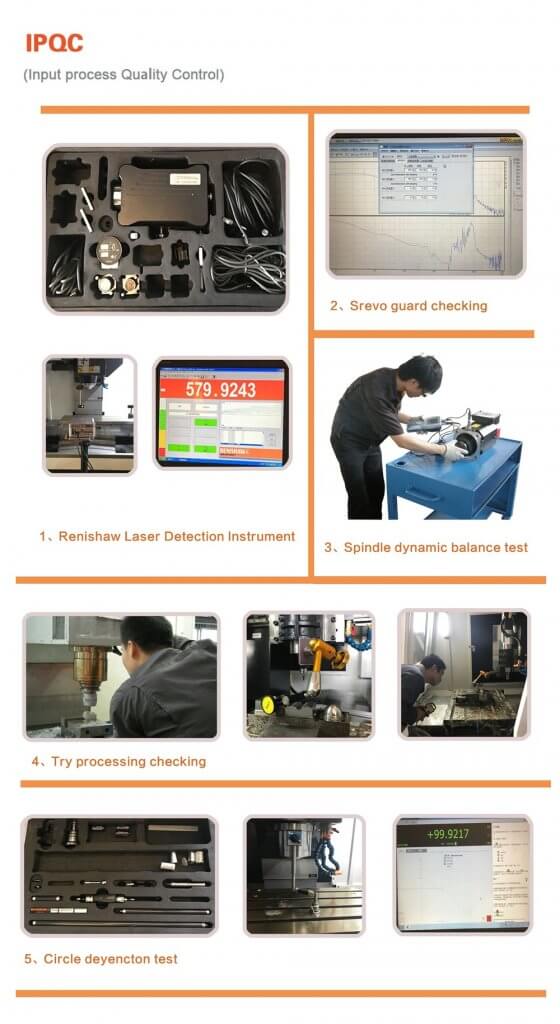

Every machine tool produced by TAICNC is produced in strict accordance with the ISO standard. During this process, a variety of quality management tests will be carried out. We must ensure that all the CNC machine tools delivered to our customers are qualified and perfect.

A sophisticated laser unit is employed to inspect the three-axis accuracy.Including linear positioning, positioning, accuracy, pitch error, and backlash, etc.

use a ball bar tester is employed for inspecting servo accuracy, static and dynamic geometric errors.

Production sample

TC-V8 high speed CNC milling machine can do a lot of work this is only part of it, it can process a lot of materials such as copper, aluminum, steel, Bakelite and so on, can be used in various fields, if you are not sure Whether to meet your requirements welcome to contact us.

About packaging and shipping

We use strict packaging for all machine tools to ensure that it will not be damaged during transportation. We have good cooperation with many transportation companies. We must ensure that the machine can be transported safely and on time to your factory.

TAICNC certificate

TAICNC has passed the ISO9001 / 14001 certification and CE certification, obtained a number of national patents, and strictly comply with manufacturing standards.

TAICNC manufacturing factory show

We have a sound management system and a clean factory, which is the first condition to ensure product quality.