What is the role of Vertical Machining Center Pallet Changer? Do you know?

In this content, we will take you to understand the role of vertical machining center pallet changer and its characteristics.

What is Vertical Machining Center Pallet Changer

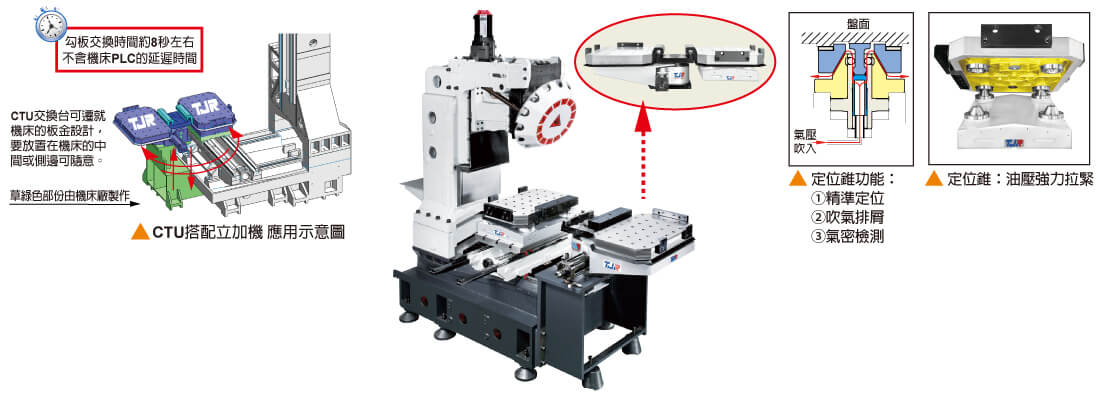

The pallet changer, is configured to perform continuous cutting on one side while inspecting, disassembling and installing the workpiece on the other (thus saving time for assembly and disassembly of the workpiece), greatly improving production efficiency and saving staff and factory space.

Note that: the worktable is fully automatic rotation, only 10 seconds, the table repeat precision 0.01.

There are two main exchange forms of pallet changer: linear exchange and rotary exchange. The linear exchange covers a large area and the exchange speed is slow. With the increasing specifications of domestic horizontal machining center machine tools, the maximum load of, pallet changer continues to improve. The higher request is put forward to the exchange device of the worktable.

Vertical Machining Center Pallet Changer Job Video

Vertical machining center pallet changer has the following features…

High precision 3-piece gear clutch provides high positioning accuracy and accuracy on table top.

Servo motor drive combined with gear clutch positioning makes the unit suitable for flexible angular machining.

Dual lead worm transmission provides minimum positioning time and allows for reversible rotation.

Powerful hydraulic locking system suits heavy duty machining

Can be online with CNC boring machine to serve as a fourth spindle, or used together as a single axis controller.

vertical machining center pallet changer parameters

| CTU-400×600 | CTU-500×700 |

|---|---|

| Hook type (U type) | Hook type (U type) |

| □ 400 x 600 | □ 500 x 700 |

| Hydraulic hirth coupling | Hydraulic hirth coupling |

| 180º to and fro | 180º to and fro |

| Hydraulic 35 | |

| Cone positioning | Cone positioning |

| 960×4=3840 | 960×4=3840 |

| Hydraulic 45 | |

| 2860 | 2860 |

| 60 | 60 |

| 250×2=500 | 250×2=500 |

| Inspection accuracy | |

| 0.01 | |

| 0.02 | |

| 0.02 | |

| 255 | |

| 530 | 603 |