Best VMC850 CNC Vertical Machining Center

If you are looking for high quality VMC850 CNC Vertical Machining Center or CNC Milling Machine then you are in the right place.

TAICNC as the best VMC850 machine manufacturer and supplier in China, we manufacture and supply multiple specifications of VMC850 CNC milling machines for selection. The VMC850 machining center is suitable for applications in various industries, whether you are using it for molds or parts manufacturing, it can 100% meet your needs. Both light milling and heavy milling are its forte and are currently being sold at manufacturer prices.

1000 Set/Month

20 Years Experience

24H support

CE certification

RECOMMENDED PRODUCTS

VMC850 CNC vertical machining center for sale

As a vertical machining center manufacturing expert, our VMC850 CNC vertical machining center has a variety of specifications to choose from.

They differ in Z-axis stroke, spindle speed, and guideway type.

In the basic configuration, you can also choose to add a 4 axis rotary table or a 5 axis rotary table to achieve 4 axis or 5 axis machining capabilities.

The excellent structural design and powerful core components make the VMC850 machining center have more powerful milling ability and machining accuracy.

TC-856L Vertical Machining Center

CHECK DETAILS

TC-855L Vertical Machining Center

CHECK DETAILS

TC-V855 Vertical Machining Center

CHECK DETAILS

Still can’t find your vertical machining center?

Contact Our Experts For A Professional & Cost-Effective Solution

Advantages of VMC850 CNC vertical machining center

VMC850 CNC vertical machining centers are all cast with the best casting materials. The actual processing needs are fully considered in the design, and they have the characteristics of high rigidity, high stability and high precision.

In the appearance design, the beautiful and fashionable design is fully applied to facilitate the operator to operate the machine better.

A variety of popular CNC controllers are available for users to choose to meet the usage habits of different customers.

Let’s see what is unique about the VMC850 CNC vertical machining center.

best casting material

- Our vertical machining centers are all cast with the best meehanite cast iron (GB 300A+).

- The base adopts high-precision linear guide, which can realize high-speed cutting. We also offer the option of block rail construction, a must for heavy duty milling. For optimum stability when performing heavy milling.

best structural design

- All vertical machining centers are professionally analyzed and designed by designers with rich experience in machine tool design.

- It is processed by professional mold manufacturing and the best processing equipment. The contact surface adopts the best scraping to ensure the accuracy and stability of the machine tool.

Stable long-span column

- VMC 850 CNC Vertical Machining Center adopts a large-span column design, which can improve machine stability and reduce vibration during machining.

- Box-shaped structure, large-span A-pillar, high rigidity, ensuring processing stability.

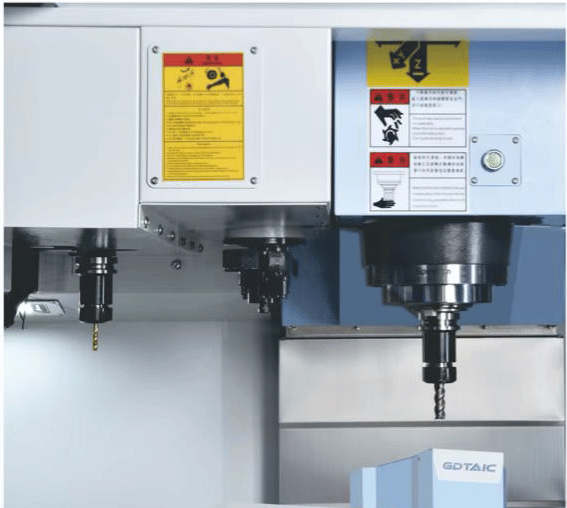

Totally closed ATC

- Fully enclosed automatic tool changer, which can effectively reduce the entanglement of iron filings on the tool

- Servo ATC, two-way type, random tool selection.

- Tool change can be quickly accomplished in only 2 seconds(tool to tool)

- The maximum tool capacity is 24PCS, and there are more custom options.

4-axis or 5-axis optional

- TAICNC VMC machine provides 4 axis and 5 axis options. By choosing them, you can complete more complex processing, reduce the number of clamping of parts, and can complete the clamping to process multiple faces at one time.

- Rugged 4/5 axis rotary table for excellent indexing accuracy and repeatability. The smallest division unit is 0.001 degrees.

High speed spindle

TAICNC vertical machining center provides a variety of taper spindle options, such as BT, BBT and other spindle types.

The transmission mode can choose belt type, direct connection type, gear type and so on. The equipped spindles all have the characteristics of high rigidity, and the maximum spindle speed ranges from 6000 to 15000 rpm.

Best Circuit Design

- Each of our VMC machine circuits are designed and completed by electrical engineers. The internal control system adopts self-designed integrated circuits to operate, which can ensure stable operation.

After strict inspection and testing, CNC vertical milling machines can be delivered to customers. - All circuit components use international brands such as Schneider to ensure the overall quality of the machine tool.

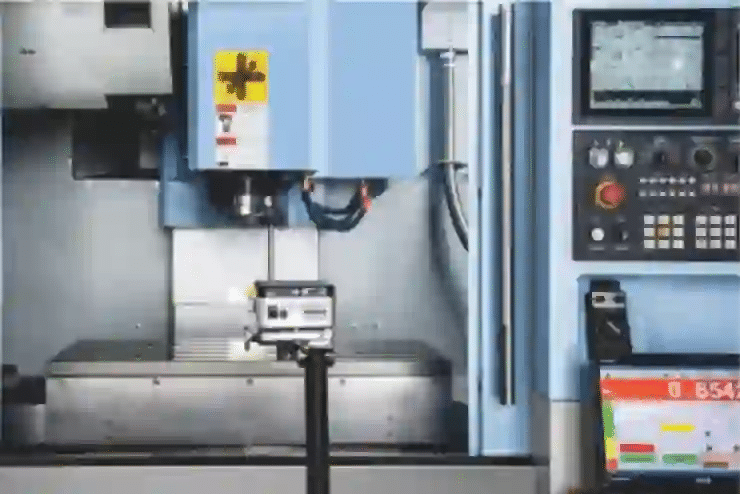

CNC controller optional

CNC controller is the brain of CNC vertical machining center. Our VMC machine is equipped with popular CNC controller, which is convenient for operators to use quickly and skillfully.

Including a variety of economical CNC controllers and high-end CNC controllers, they all have excellent performance and can meet the needs of your machine tools in actual work.

strict quality control

- We have strict standard operating procedures (SOPs) and quality management.

- Each vertical CNC mill uses a precision laser unit to detect triaxial accuracy, including linear positioning, positioning, accuracy, pitch error, and backlash, etc.

- Use a ball bar tester is employed for inspecting servo accuracy, static and dynamic geometric errors.

THE ULTIMATE FAQ GUIDE

VMC850 CNC Vertical Machining Center

1.What is VMC850 CNC vertical machining center?

VMC850 CNC vertical machining center is also called CNC milling machine or VMC machine.

VMC850 table size is usually 1000×500mm.

X, Y, Z axis travel is usually 800×500×500mm.

Because of its large enough processing range and strong milling capability, the VMC850 machining center has always been the most popular vertical machining center in the market.

It is widely used in various parts and mold manufacturing, and it also has a strong advantage in heavy milling capabilities.

The VMC850 machining center manufactured by TAICNC is upgraded and transformed. Our current model is TC-855L or TC-856L. They have a larger table size and X, Y, and Z-axis strokes than the traditional VMC850 machining center. The structure is also It has been optimized to make its processing capacity stronger.

2. What are the types of VMC850 CNC vertical machining centers?

VMC850 CNC vertical machining center can be divided into the following types according to the number of axes:

- 3 axis VMC850 vertical machining center

- 4 axis VMC850 vertical machining center

- 5 axis VMC850 vertical machining center

Among them, the standard configuration is 3 axes, that is, X, Y, and Z axes.

The 4-axis and 5-axis are based on the 3-axis by adding a rotary table to achieve 4-axis and 5-axis linkage.

3. Where is the VMC850 CNC vertical machining center manufactured?

TAICNC’s manufacturing plant is located in Dongguan, Guangdong, China, where our VMC850 machines are designed, manufactured, and tested.

Its core components such as ball screws, linear guides, and CNC controllers are all supplied by our global popular core suppliers.

4. What can I expect from the quality of the VMC850 CNC vertical machining center?

You can rely on our machines to meet the highest international quality standards for CNC equipment. We ensure that each machine meets the necessary specifications documented in our inspection reports.

Our manufacturing fully complies with the ISO9001:2015 standard specification, and we have strict SOP processes and quality control procedures from the casting, processing, and assembly of core components.

After the manufacturing is completed, each VMC machine will be delivered to the customer after strict inspection and trial processing are 100% qualified.

5. Why are your VMC850 machines more expensive than other suppliers?

Our machines are worth the money. You can rely on us to provide the highest quality products, and while there are cheaper alternatives on the market, they may not always provide the best results.

There are many VMC850 CNC vertical machining centers on the market, if you choose Chinese suppliers, almost only China and Taiwan produce them. Regardless of whether you choose TAICNC or not, I suggest you choose suppliers from Guangdong or Zhejiang and Shanghai.

There is a saying in China that you get what you pay for, and quality cannot be sacrificed for cheap. Different suppliers have great differences in casting materials, assembly processes, quality of core components, and testing instruments.

6. What is the price of VMC850 CNC vertical machining center?

There are many factors that affect the price of VMC850 CNC vertical machining center, as follows:

- Brand

- Processing range

- Number of axes

- Place of origin

- CNC controller

- Core component brand

If you import VMC850 CNC machine from China, I can give you an approximate reference price.

- 3 Axis VMC850 CNC Vertical Machining Center Price $33,000-$45,000

- 4 Axis VMC850 CNC Vertical Machining Center Price $37,000-$50,000

- 5 Axis VMC850 CNC Vertical Machining Center Price $51,000-$62,000

Because there are many factors that affect the price, the above price is for reference only, if you have any questions, please contact our experts.

Rating

Your page rank: