Whether imported machining center, machining center in Taiwan or China machining centers, machining centers itself on, even the same brand, the same model of a vertical machining center, the configuration of their different prices are different.

CNC Controller is an important factor in determining the price of the machining center

Thus a CNC controller brain vertical machining center, the machining center of all actions, procedures are relying on it to complete. At present, several mainstream systems on the market include foreign system brands, Japan’s Mitsubishi, Japan’s Fanuc, Germany’s Siemens, and HEIDENHAIN controllers. It should be noted that these systems are bundled with three-axis servo motors, that is if If your controller is Mitsubishi, you must purchase Mitsubishi’s servo drive and motor.

Taiwan CNC controller brand Taiwan SYNTEC CNC controller and Taiwan LNC CNC controller, Taiwan CNC controller can freely match the servo drive and servo motor of other manufacturers, no limit, China CNC controller brand GSK CNC controller and Huazhong CNC controller Beijing KND CNC controller.

When selecting a CNC controller, it is necessary to integrate various factors, such as the use of environmental workpieces, processing technology procurement budget, etc. If you choose a three-axis vertical machining center to process the mold, you can choose Fanuc0iMD-A CNC controller or Mitsubishi M70-A CNC control.

For processing products, you can choose Fanuc0iMD-B numerical control controller or Mitsubishi M70-B numerical control controller. Siemens 840D or Fanuc31i is recommended when selecting five-axis vertical plus time system. If used for teaching, you can choose Huazhong or GSK five. Axis controller. In the case of low processing requirements and limited budget, China CNC controller or Taiwan CNC controller can be selected.

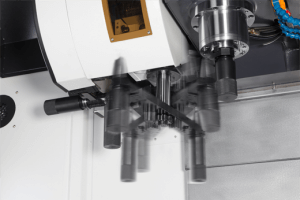

Automatic tool changer is the main factor determining the vertical machining center

The high efficiency of the machining center is not only because there is a fine numerical control controller, but also a very important auxiliary function. This is the automatic tool change device. The automatic tool change device is the container for storing the tool in the machining center, and the automatic tool change device is replaced. Knife time plays an important role in the efficiency of a machine tool. The automatic tool change device commonly used in vertical machining centers includes a bucket type automatic tool change device and an arm type automatic tool change device. The arm type automatic tool change device is also called a disc type automatic tool change device or a knife arm type automatic tool change device.