As a CNC machining practitioner, do you know the automatic tool changer?

In today’s fast-paced world, manufacturing is constantly looking for ways to increase efficiency, accuracy and productivity. One of the innovations that revolutionized the machining process was the automatic tool changer (ATC).

This versatile device not only saves time and labor, but also improves precision and safety in various manufacturing operations.

Read this article to gain a comprehensive understanding of automatic tool changers and their common types.

We’ll dive into the world of ATCs, explaining their purpose, benefits, and four popular types widely used in the industry.

Whether you are a seasoned professional or new to manufacturing, this article will provide valuable insight to help you make an informed decision when selecting the right ATC for your needs.

1. What is an automatic tool changer?

The automatic tool changer is called ATC for short, and it can also be called a tool magazine.

It is the main core component of the CNC machining center machine.

An automatic tool changer (ATC) is a device used in manufacturing and machining to automatically change tools during production without human intervention.

In simple terms, it is like a robot that helps the machine switch between different tools quickly and efficiently.

Imagine you’re working on a project that requires you to use different tools, such as a hammer, screwdriver, and wrench.

Instead of constantly stopping work to switch between these tools manually, the automatic tool changer will do the job for you, saving time and effort.

By using ATC, manufacturers can significantly speed up production, reduce errors caused by manual tool changes, and increase the precision and accuracy of their products.

In short, automatic tool changers play a vital role in making manufacturing processes faster, more efficient, and more reliable.

But there are many types of automatic tool changers.

Wondering what types are there?

Keep reading and you will get the answer you want.

2. What are the types of automatic tool changer (ATC)

We all know that there are many types of CNC machining centers.

There are also many types of automatic tool changers as its core component.

Different types of CNC machining centers can be installed with different automatic tool changers. There are mainly 4 types that we commonly see:

- Carousel (or Rotary) automatic tool changer

- Gripping type automatic tool changer

- Arm type automatic tool changer

- Chain automatic tool changer

The above are the 4 common automatic tool changers, and we will introduce them in detail below.

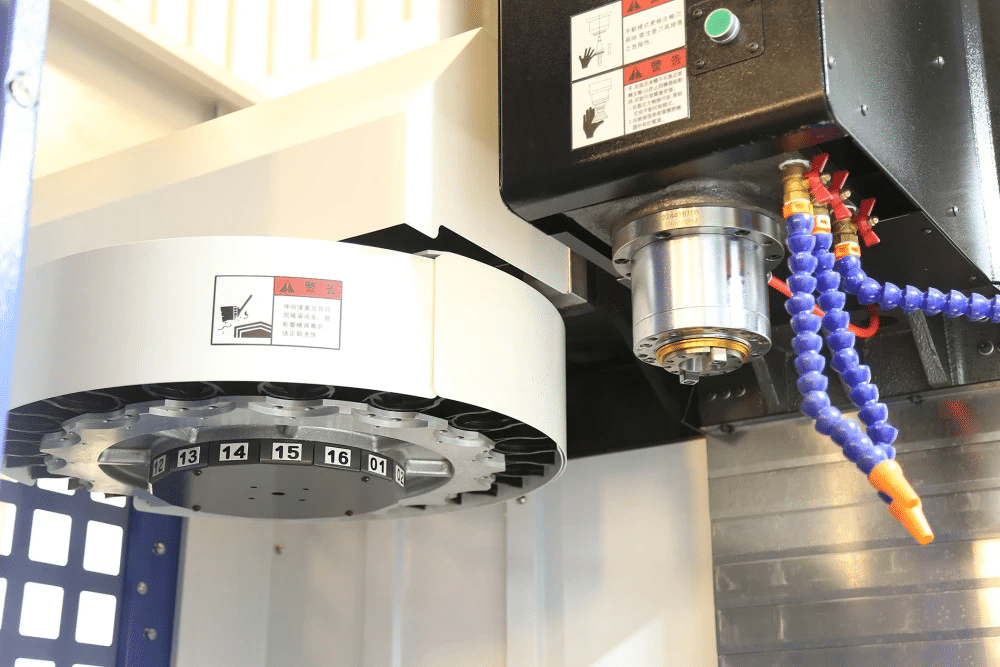

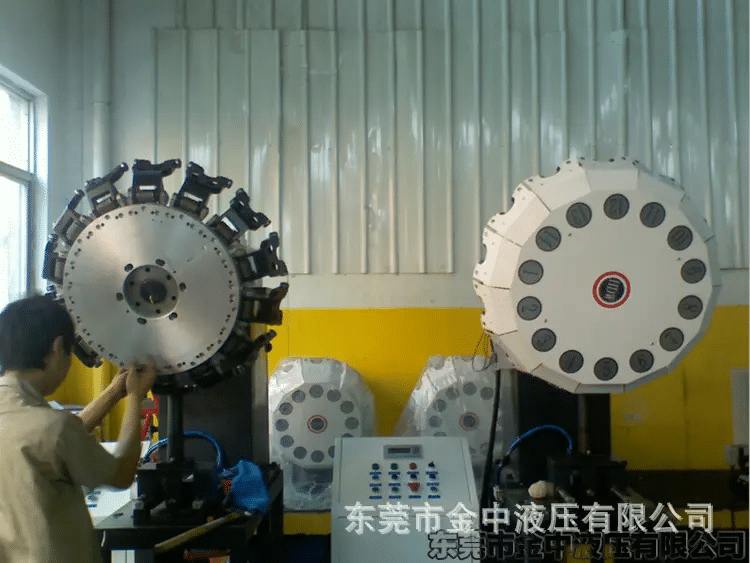

2.1 Carousel (or Rotary) automatic tool changer

Carousel (or Rotary) automatic tool changer is designed with a horizontal circular tool magazine, which is like an umbrella, so we also call it an umbrella-type automatic tool changer.

This type of ATC generally can only store 16 to 20 tools, and the entire tool magazine will move below the spindle when changing tools.

When the tool on the spindle enters the slot in the tool magazine, the spindle moves up and away from the tool.

At this time, the tool magazine rotates. When the tool changer is directly below the positive spindle, the spindle moves down to make the tool enter the taper hole of the spindle. After the tool is clamped, the tool magazine returns to its original position.

The Carousel ATC is known for its compact design that saves space in the workspace of CNC machines.

They offer moderate tool capacity and are suitable for small to medium CNC machines.

Advantage

- cheap price

- Small space

Shortcoming

- High failure rate

- Long tool change times

- Tool magazine capacity is small

2.2 Gripping type automatic tool changer

Gripping type ATC is a front-mounted tool magazine, which is generally used in CNC tapping centers.

For example, Fanuc and Brother small machining centers use this type of automatic tool changer.

The tool capacity of this type of automatic tool changer is usually 16 or 21 PCS.

Usually aluminum alloy recast one-piece tool holder set, quick assembly and replacement.

Since there is no separate tool change arm structure, the tool change is performed directly between the spindle and the tool magazine. Compared with other tool magazine types, the auxiliary tool change time of the tool change arm is reduced.

Therefore, the tool change speed of Gripping type ATC is relatively fast, and the tool change time between adjacent tools can be controlled within 1 second.

Advantage

- Low failure rate

- Fast tool change

- cheap price

Shortcoming

- Tool capacity is small

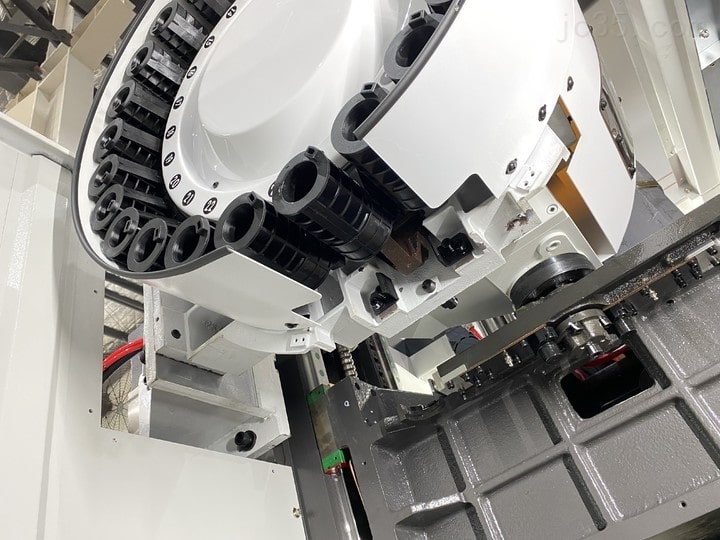

2.3 Arm type automatic tool changer

Arm ATC is the most common type of tool changer we see in vertical machining centers.

This type of ATC usually has a moderate tool capacity, 24 to 30PCS, and can accommodate a variety of spindle tapers, BT40 or BT50.

Arm-type tool changers feature a double-arm mechanism that allows for simultaneous tool exchange.

While one arm delivers the new tool to the spindle, the other arm retrieves the previously used tool from the spindle. Usually the tool change time is within 2 seconds.

This design enables faster tool changes, reducing the machine’s idle time. Arm-type tool changers are suitable for various CNC machines, including milling, turning, and multitasking centers.

Advantage

- Fast tool change time

- fair price

- Applicable to various tapers

- Low failure rate

Shortcoming

- Take up a lot of space

- Easy to entangle iron filings

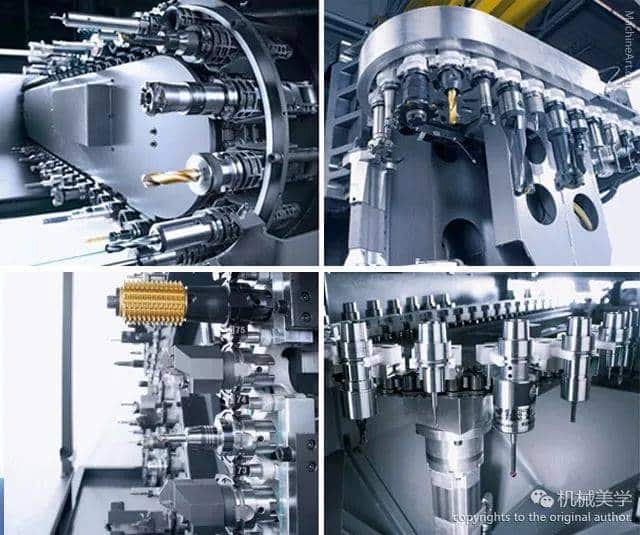

2.4 Chain tpye automatic tool changer

Chain tool changers use a linear magazine, where tools are stored in a chain-like configuration.

It is the largest automatic tool changer ever manufactured.

The tool changer arm moves along the chain to pick up the desired tool and bring it to the spindle.

Chain tool changers usually have a higher tool capacity compared to carousel tool changers and can accommodate larger tools.

Chain ATC usually has a tool capacity of 60 to 200 pcs, this type of automatic tool changer is usually customized according to the type of CNC machine.

They are usually used in large vertical machining centers, 5-axis machining centers, horizontal machining centers, double column machining centers, etc.

Advantage

- Large tool capacity

- Applicable to various tapers

Shortcoming

- Expensive

- Tool change speed is slow

- Take up a lot of space

- High failure rate

3. What type of ATC should I choose?

After reading the above introduction, do you have enough understanding of the automatic tool changer?

If you are thinking of buying a CNC machining center but don’t know how to choose an automatic tool changer, I can give you some advice.

If you want to buy a regular size vertical machining center or horizontal machining center, you can directly choose the arm type automatic tool changer.

It has the characteristics of fast tool changing speed, low failure rate and reasonable price. It is our most common automatic tool changing device. You can choose 24 or 30PCS tool capacity, which is usually according to your needs.

If you want to buy a CNC tapping center, you can only choose the gripping type automatic tool changer, which has a fast tool change speed and can choose as much tool capacity as possible.

If you are buying a larger CNC machine, you can choose a chain automatic tool changer, which usually requires customization and is expensive.

In conclusion, each type of automatic tool changer has its advantages and limitations, and the choice depends on factors such as tool capacity requirements, machine size, production volume, and budget constraints.

By evaluating these factors, you can choose the ATC that best suits their specific needs, increasing the productivity and efficiency of their machining process.