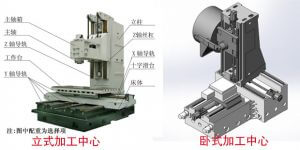

What is the difference between a vertical machining center and a horizontal machining center?

horizontal machining center and the vertical machining center have in common that the milling function is the main function. The difference between the two is that they have different structures, different positioning of the products, and different forms of machining the workpiece.

horizontal machining structure of the horizontal machining center and the vertical machining center are different.

The horizontal machining center refers to the machining center where the main shaft is horizontal; the vertical machining center refers to the machining center where the main shaft is vertical.

horizontal machining center and the vertical machining center are different.

The vertical machining center’s vertical columns are designed as moving column type, and the positive T-shaped horizontal machining center moves its column in the X direction. The inverted T-shaped horizontal machining center moves its column in the Z direction. Moving the structure of the column requires that the column must be as light as possible on the premise of satisfying the rigidity. Imported machine tools often use steel plate welded structures to achieve such a purpose.

columns of the vertical machining center are generally designed to be non-moving. In order to pursue rigidity, it is generally made as thick as possible during manufacture. Occasionally, there is also a vertical column machining center designed for moving columns. The vertical column machining center table only performs the X or Y direction movement, while the column will do the Y or X direction movement. This design method has the better comparison with the column drive motor. Large power requirements.

horizontal machining center and the vertical machining center work table are different in form.

the workbench of the horizontal machining center is only designed to move in the X or Y direction. The workbench is generally a rotary table with a lattice screw hole table. It is relatively easy to choose an exchange double table.

Vertical machining center workbench, usually a T-slot workbench with a cross slide structure. There are two sets of motion mechanisms responsible for vertical movement. The X-feed table is covered on the guide rail for Y-feed.

Horizontal machining centers and vertical machining centers have different chip removal conditions.

Due to the structural characteristics of the vertical machining center, the chips are not easily discharged when machining the cavity or the concave profile. In severe cases, the tool will be damaged and the processed surface will be damaged, which will affect the smooth processing.

horizontal machining center has easy chip removal during processing, and the processing condition is relatively ideal.

Horizontal machining centers and vertical machining centers operate differently.

Generally, the workpieces processed by the horizontal machining center are relatively large, and the clamping is difficult. It is not easy to monitor the machining process, and the operation and debugging are relatively difficult.

Vertical machining center clamping is generally convenient, easy to operate, easy to observe processing conditions, and easy to debug.

Horizontal machining centers and vertical machining centers have different processing objects.

horizontal machining center generally finishes the processing of the other four surfaces except for the mounting surface and the top surface after one clamping and is suitable for processing the box-like parts. After the angle head is added, the pentahedron processing can be realized.

vertical machining center is limited by the height of the column and the tool changer. It can’t process parts that are too high. It is suitable for processing discs, sleeves and plate parts. The volume of the workpiece is relatively small. If you want to realize the side machining of the workpiece, you must add Angle head or CNC turntable. If you install a turntable that rotates along the horizontal axis on the workbench, you can use it to machine spiral parts.

To sum up: the horizontal machining center has more structural complexity than the vertical machining center. The number of factories capable of producing horizontal machining centers is much smaller than that of vertical machining centers. The horizontal machining centers of the same working range are often vertical machining centers. More than twice.