What is the difference between CNC lathes and CNC milling machines? Are you being troubled by this problem?

Don’t worry, you will understand very well after reading the following content.

What is CNC?

A CNC (Computer Numerical Control) Router is one of the most important devices for creating custom made implements, which are used in a variety of industries. Two primary methods use this technology – CNC lathing and CNC milling – and each has its bundle of pros and cons.

CNC milling and CNC turning have made it possible to create patterns and add detail to metal components that are not possible by hand. What are the differences between CNC milling machine and CNC lathe ?

What is CNC turning?

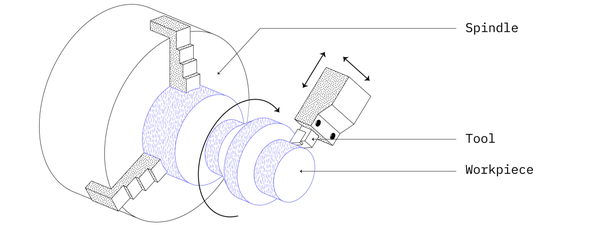

Turning is a slightly different process compared to CNC milling. CNC lathe relies upon computer-controlled machines, but creates a different end product. The process uses a single-point cutting tool that is inserted parallel to the material that will be cut. The material ( metal, plastic, etc.) is rotated at varying speeds and the cutting tool traverses the 2 axis of motion to produce cylindrical cuts with exact depths and diameters.

In CNC turning, the part is mounted on a rotating chuck and material is removed using stationary cutting tools. This way parts with symmetry along their center axis can be manufactured. Turned parts are typically produced faster (and at a lower cost) than milled parts.

As mentioned, CNC turning is used to create objects with round or tubular shapes that are created from larger pieces of material. A drive shaft is a simple example of an object that could be created using CNC turning. Other examples include tubing and custom couplings for plumbing or other applications.

What is CNC milling?

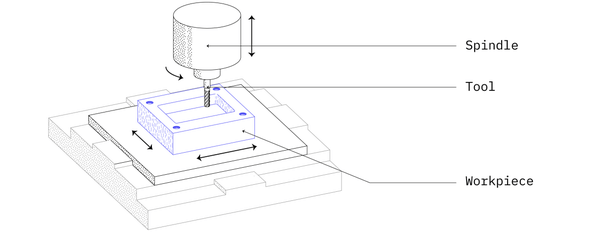

CNC milling is the most popular CNC machine setup. In fact, the term CNC milling is often synonymous with the term CNC machining. Most CNC milling systems have 3 linear degrees of freedom: the X, Y and Z axis.

CNC milling consists of a milling machine that uses commands, or G-codes, programmed into the machine via a computer software program. Each code entered into the program has a designated function that is performed by the machine. When codes are entered into a CNC program representing a potential finished product, the mill then drills and turns along axes to cut and shape the material to match the dimensions entered into the computer.

The workpiece is held stationary on the machine bed or in a vice. Material is removed from the workpiece using cutting tools or drills that rotate at high speed. The tools are attached to a spindle, which can move along the 3 axis.

Tool access can be a design restriction in CNC milling. As there are only three axes to work with, certain areas might be impossible to reach. This is not a big issue if the workpiece needs to be rotated just once, but if multiple rotations are needed the labor and machining costs increase fast.

In Summation

CNC milling machines and CNC lathes are two different CNC machines, their processing methods and machine structure are very different.

CNC lathes and CNC milling machines play a very important role in metal processing.

it is important to note that there are differences between CNC lathing and CNC milling, with the primary difference being that a CNC lathe is stationary, while a CNC milling machine will move about as according to the program controlling it. In either case, CNC machines are used to make all sorts of useful items from electronics to nameplates.

Part of the content comes from LinkedIn