Still can’t find your horizontal machining center?

CNC horizontal machining center is also called CNC horizontal milling machine or HMC machine, if you are looking for CNC horizontal machining center, then you are in the right place.

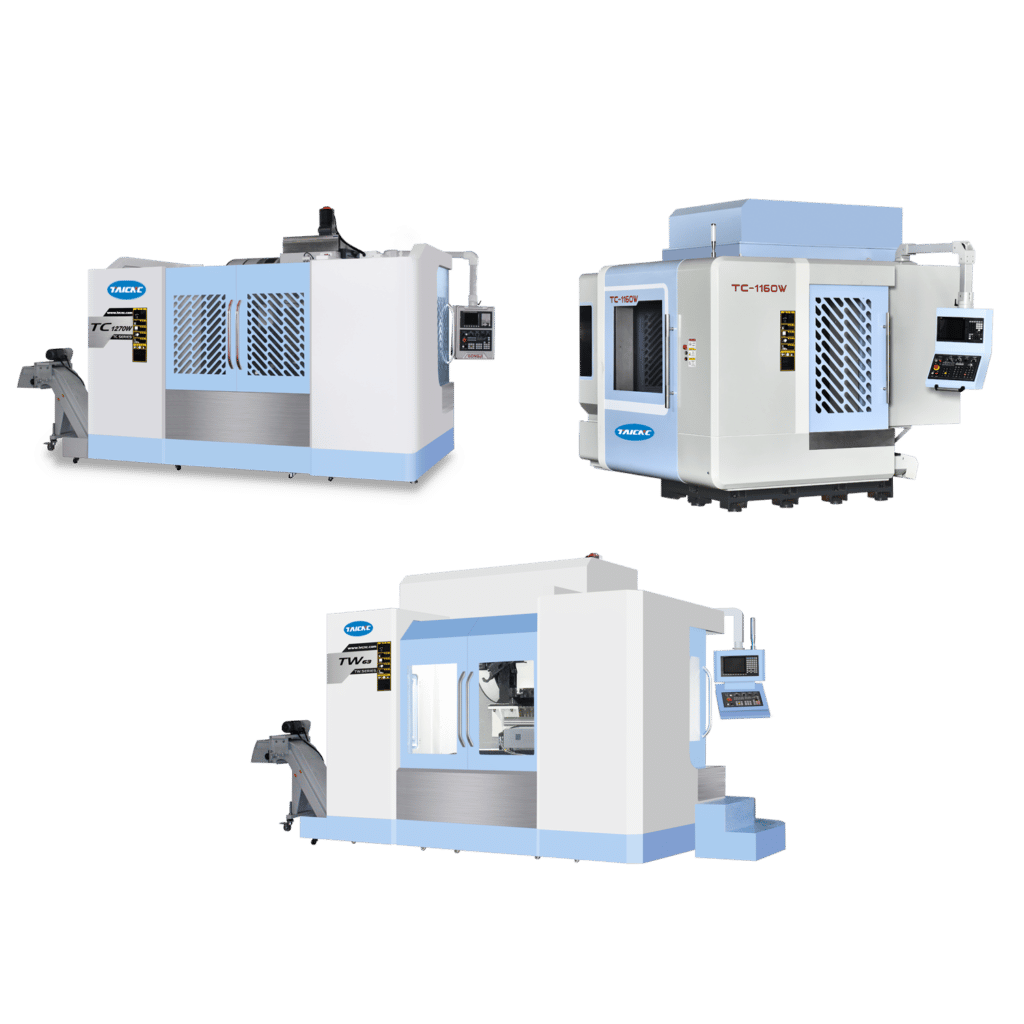

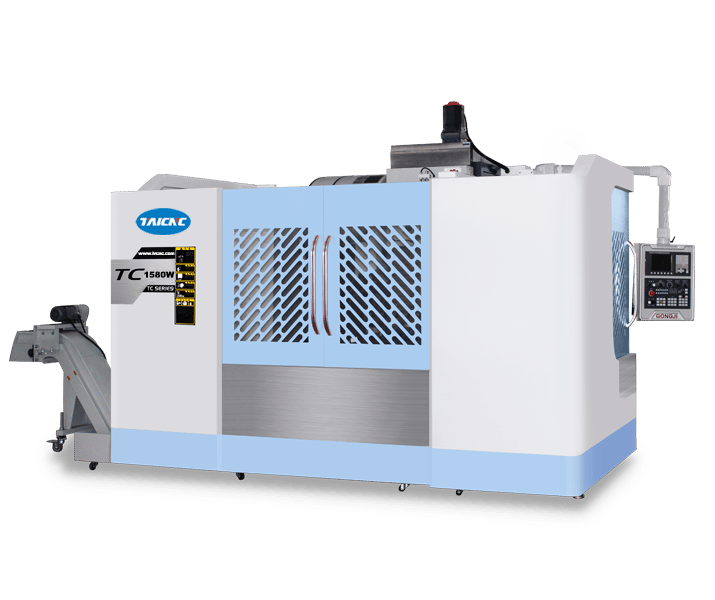

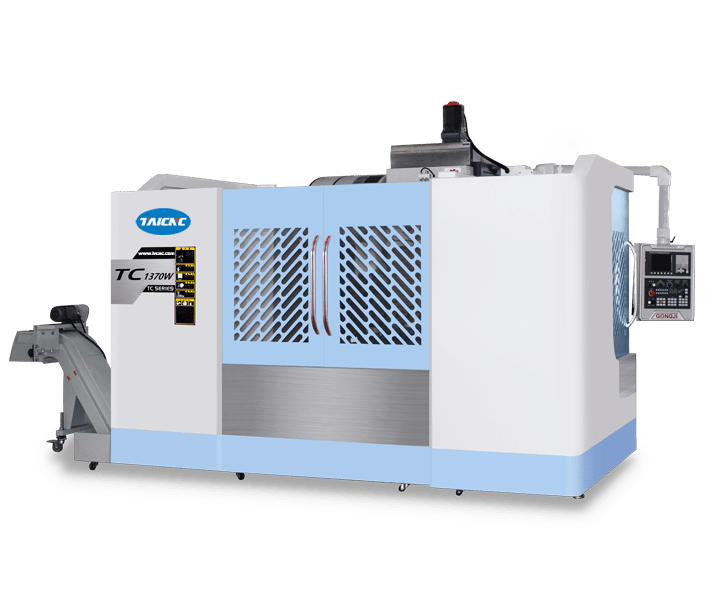

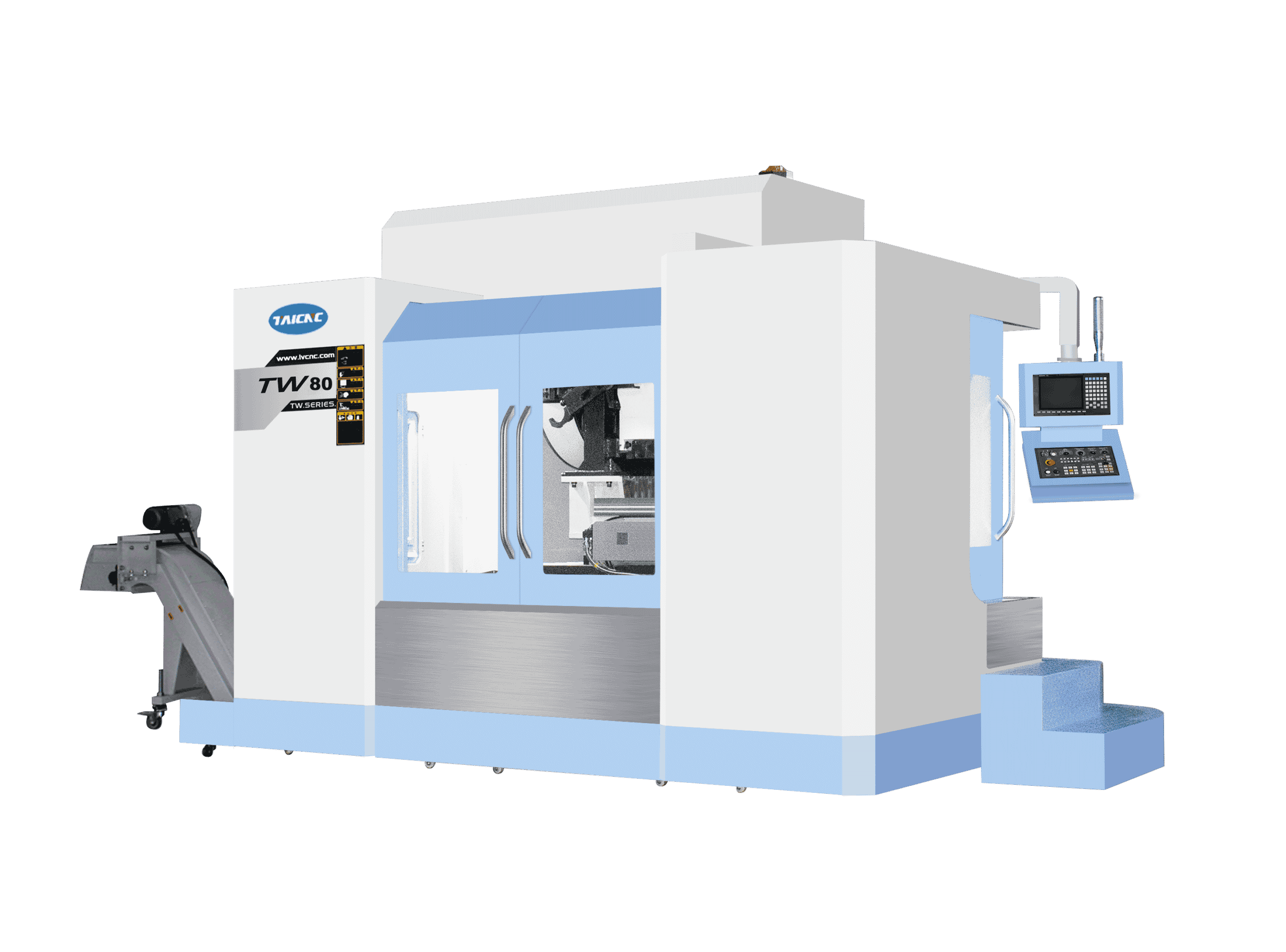

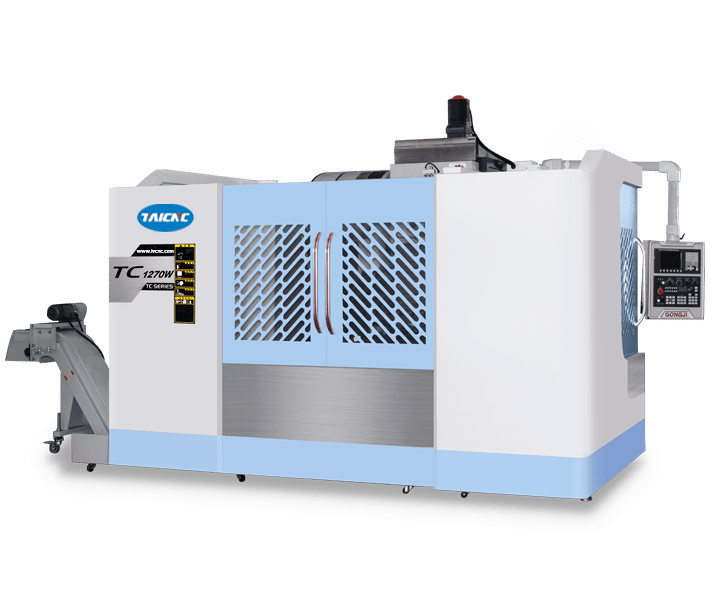

TAICNC is a leading manufacturer and supplier of CNC horizontal machining centers in China. With 20 years of experience in CNC machine tool manufacturing, our HMC machines are widely praised by customers all over the world. Whether you need CNC vertical and horizontal machining centers, CNC horizontal milling machines, we can meet your needs. Our horizontal machining centers are widely used in the manufacture of various parts and sold at manufacturer prices

TAICNC is a manufacturing specialist for CNC horizontal machining centers. We provide high-quality, high-precision, and stable horizontal machining centers for various industries.

Whether you need a small horizontal machining center or a large horizontal machining center, we have a horizontal machining center specification to meet your needs.

Our Horizontal Machining Centers are suitable for any industry, selling Horizontal Machining Centers at manufacturer prices, you can get exclusive offers from the best Horizontal Machining Center suppliers in China.

Still can’t find your horizontal machining center?

TAICNC is an expert in the manufacture of horizontal machining centers, and each horizontal machining center is cast with high-quality casting materials.

In the design, the actual processing needs are fully considered, and the best structural design is adopted to improve the precision and stability of the CNC machine.

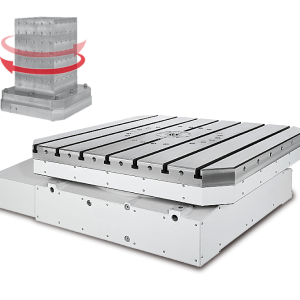

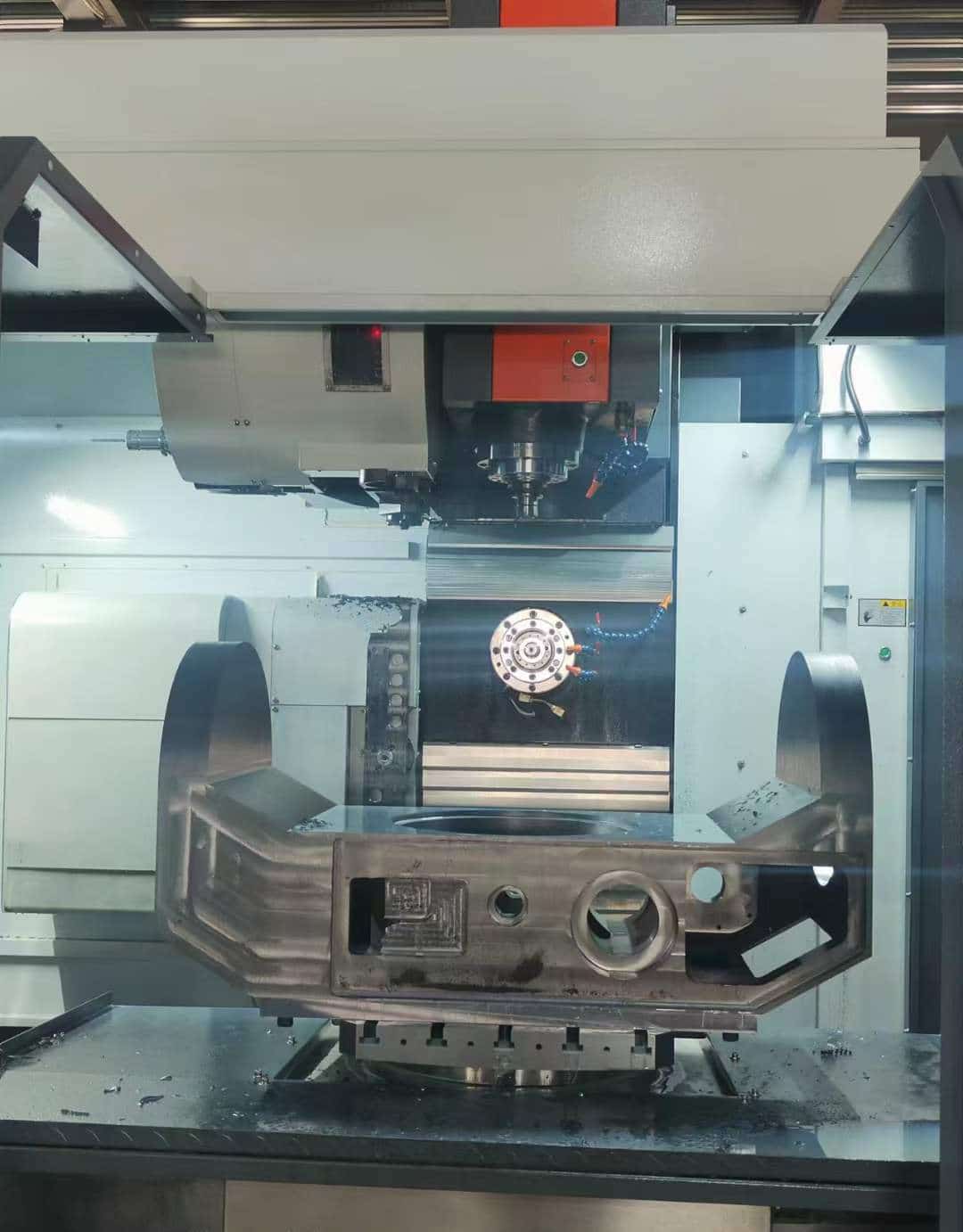

The horizontal machining center is equipped with a 360-degree rotating table, which can realize the processing of 4 surfaces in one clamping, and is a powerful tool for processing box products. There are a variety of CNC systems and servo motors to choose from, to maximize the use habits of customers around the world.

Our horizontal machining centers are designed according to international standards and delivered to customers with guaranteed quality and perfect after-sales service.

A horizontal machining center is not a simple machine, and its manufacture requires the cooperation of many suppliers. TAICNC has established a long-term cooperative relationship with the world’s mainstream machine component suppliers, and their quick response can satisfy us to quickly deliver the machine to customers.

Usually CNC horizontal machining center is also called horizontal CNC milling machine, HMC machine, it is a kind of machine used for metal milling processing, which is controlled by CNC controller.

CNC (an automated machine tool controlled by a program) generally refers to a computer numerical control machine tool.

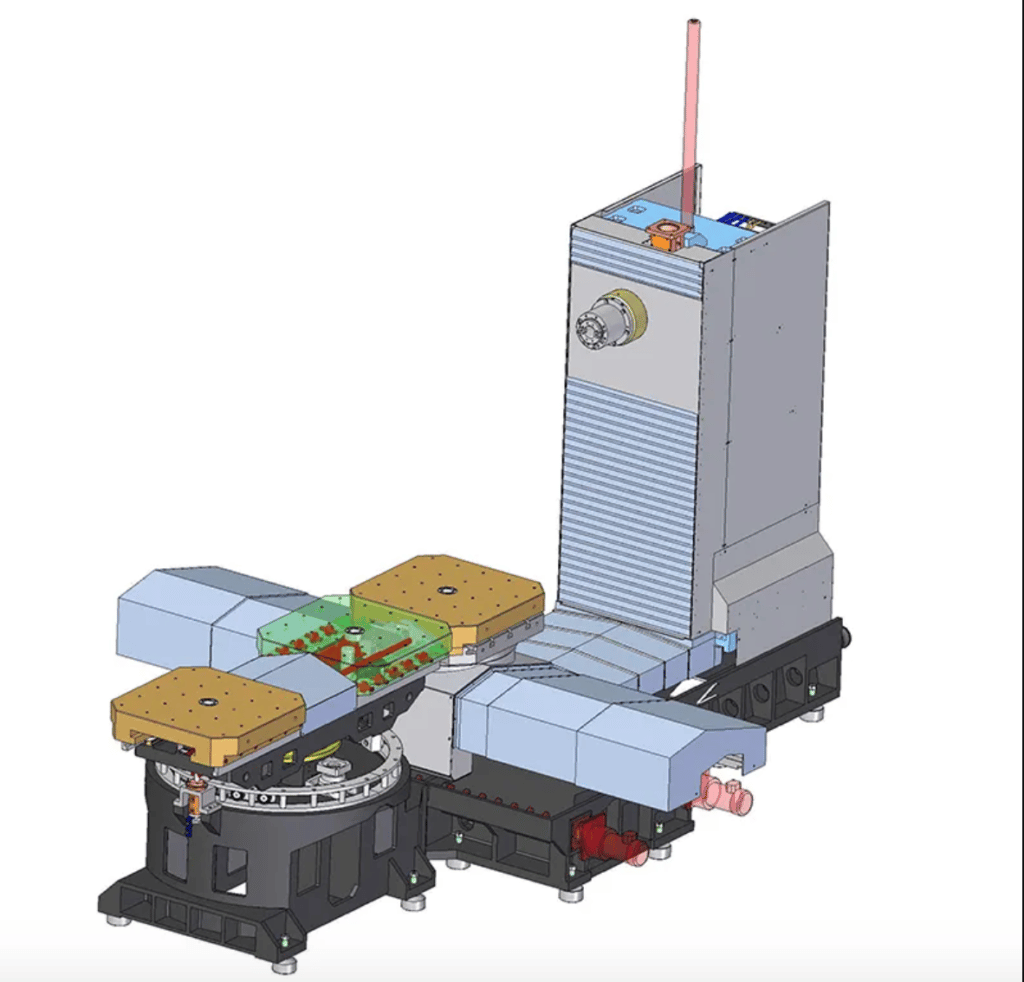

A Horizontal Machining Center (HMC) operates with its spindle in a horizontal position instead of a vertical position like a VMC.

A horizontal machining center is a computer numerically controlled (CNC) machine tool used for milling and boring operations. The machine’s spindle moves in the same plane as its table, enabling it to perform milling and boring operations.

In practical applications, horizontal machining centers are mainly suitable for processing box-type parts, and their main functions are milling, boring, and drilling.

Each horizontal machining center is equipped with a worktable that can rotate 360° so that it can complete the processing of 4 surfaces in one clamping.

In addition, TAICNC has also independently developed a vertical and horizontal machining center, which can realize vertical and horizontal 5-surface machining in one clamping.

This is equivalent to purchasing a vertical and horizontal machining center to realize the processing method that requires two machine tools.

Compared with vertical machining centers, CNC horizontal machining centers have fewer categories and mainly include the following categories:

In fact, the working principle of the horizontal machining center is similar to that of the vertical machining center.

Milling, drilling, tapping, boring and other processes are realized through the rotation of the main shaft.

It’s just that their application scenarios are different.

Due to height limitations, vertical machining centers are not suitable for processing parts that are too high.

At this time, the advantages of horizontal machining centers are reflected.

Since the main shaft of the horizontal machining center is horizontal, it does not have much limitation on the height of the parts.

The horizontal machining center is especially good at processing box and shell parts, which is its unique advantage at this time.

And it has a turntable that can rotate 360°, and one clamping can complete the processing of multiple surfaces.

If you choose TAICNC’s vertical and horizontal machining centers, it can also realize five-sided machining in one clamping.

In addition to the 3 axis machining center, do you also know the 5 axis horizontal machining center?

It is upgraded on the basis of a 3 axis horizontal machining center.

In addition to the X axis, Y axis, and Z axis, the 5 axis horizontal machining center also adds two rotation axes: A axis, B axis, and C axis.

5 axis machining involves moving a CNC cutting tool in five different axes simultaneously.

This kind of processing is a high-efficiency, high-precision process, and the processing of the workpiece is completed in one clamping.

5 axis machining is ideal for complex parts in aerospace, automotive, high precision medical devices and military.

At present, manufacturers who can manufacture 5 axis horizontal machining centers include Makino and GROB Zimmermann, which are expensive.

CNC horizontal machining centers are not as commonly used as vertical machining centers.

Due to the high price of CNC horizontal machining centers, not every company can afford it.

So what are the benefits of using a horizontal machining center? We summarize as follows:

Cost-effectiveness

Although the CNC horizontal machining center is expensive, its high efficiency can still bring you cost benefits.

In addition to efficiency, if you are doing machining, the parts processed by the horizontal machining center have higher value.

High processing efficiency

Ordinary CNC horizontal machining centers can realize four-surface machining in one clamping, and if you buy a 5-axis horizontal machining center, you can also achieve five-surface machining.

At the same time, the horizontal machining center has better rigidity, greater power, and higher feed rate, which can also greatly improve its machining efficiency.

complex processing

Since the spindle of the vertical machining center is vertically downward, the height of the parts is limited, while the horizontal machining center does not have this limitation, so it has better advantages in complex cavity parts and shell parts.

Maybe everyone knows that it is expensive when talking about horizontal machining centers.

Indeed, the entry price of a horizontal machining center is much higher than that of a vertical machining center.

There are many specifications of CNC horizontal machining centers. Even if the specifications are similar, the price difference may be relatively large.

There are many factors that affect the price of horizontal machining centers, as follows:

These factors are closely related to the price of horizontal machining centers.

If you choose to buy horizontal machining center from China, I can give you a price range for your reference, as follows:

Only the prices of 3 axis horizontal machining centers and 5 axis horizontal machining centers are listed above.

HMCs are efficient machines that can transform your business, but no one claims they’re cheap.

For example, a Haas EC-630 four-axis horizontal machining center with 50-tool capacity and two pallets starts at $350,000, while 5 axis models from the Okuma and Kitamura cost more than $500,000. Even off-brand products from DMG Mori cost hundreds of thousands.

How to choose a suitable CNC horizontal machining center is a very good question.

After all, a horizontal machining center is not cheap equipment, but a long-term and expensive investment.

Here are some key considerations on how to choose the right horizontal machining center:

I believe that after understanding the above questions, you should have the answer to how to choose a suitable horizontal machining center.

A horizontal machining center is not a simple machine, it is a complex device.

Many components are needed to manufacture a qualified horizontal machining center, and you need to understand these core components if you want to buy a horizontal machining center.

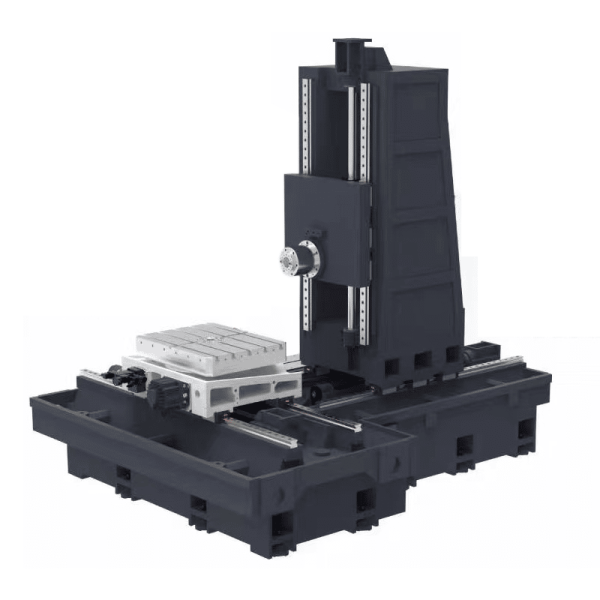

The bed is the foundation of the horizontal machining center, on which all the components are mounted.

Different types of horizontal machining centers have subtle differences in bed structure.

Beds are usually cast from cast iron. The bed of the horizontal machining center consists of two parts, one is the column and the other is the base.

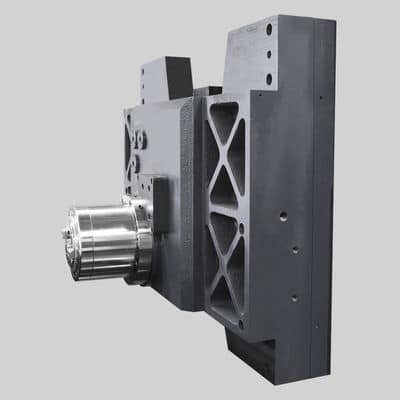

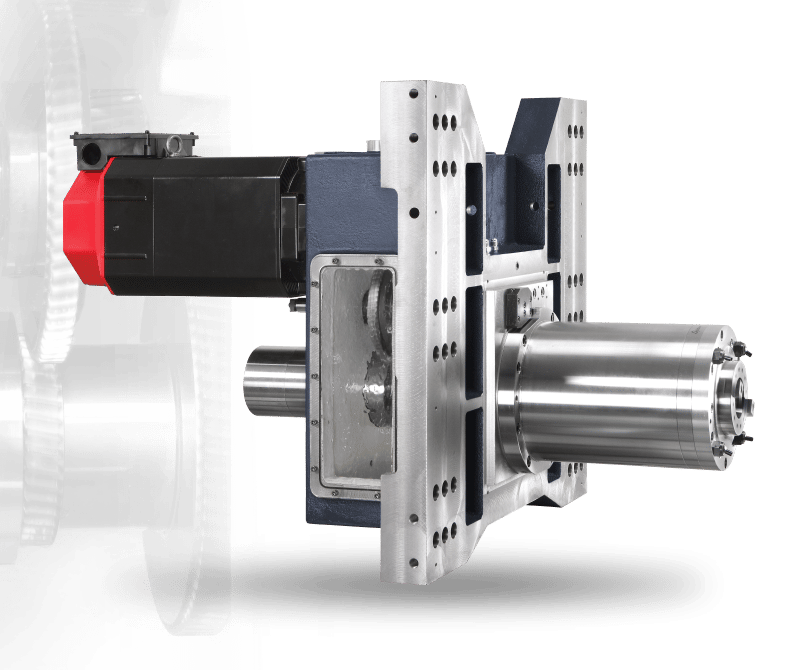

The spindle is one of the core components of the CNC horizontal machining center. All machining tasks are accomplished by the rotation of the spindle.

There are many types of horizontal machining center spindles, such as BT, BBT, HSK, etc. Different types of spindles use different tool holders.

Spindle drive mode and spindle speed are also important. The common spindle transmission methods are:

Belt spindle

Direct Drive Spindle

Built-in electric spindle

Gear spindle

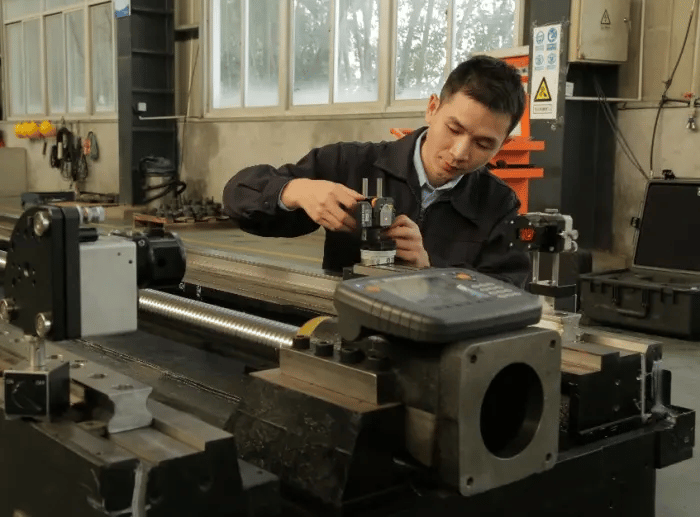

The screw and the guide rail are the core moving parts of the CNC horizontal machining center.

Its quality affects the accuracy and running speed of the horizontal machining center.

Horizontal machining centers usually use ball screw or roller linear guides, and box guides can be selected if heavy milling is required.

We have established a good cooperative relationship with many screw and guide rail brands. The screw and guide rails used by TAICNC are mainstream brands such as THK and Rexroth.

Different brands of CNC controllers have a great influence on the surface gloss accuracy.

Servo motors and drives for CNC horizontal machining centers are usually used in conjunction with a CNC controller.

The power of the servo motor determines its torque, and the torque affects the processing of the CNC milling machine.

Currently the most widely used CNC controllers are Fanuc, Mitsubishi, Siemens, Rexroth, Heidenhain and SYNTEC.

Automatic Tool Changer Affects Machining Efficiency of Horizontal Machining Center

Automatic tool changer is the core equipment of CNC horizontal machining center.

Although not required, it is helpful to improve processing efficiency.

Avoid frequent manual tool changes during actual machining.

Horizontal machining centers typically have more ATC capacity than vertical machining centers

The biggest feature of the horizontal machining center is that it is equipped with a worktable that can rotate 360°.

It can realize multiple surface processing in one clamping.

In actual use, the accuracy of the turntable is particularly important.

Horizontal machining centers usually have two sets of chip removal devices.

One is the spiral chip conveyor inside the machine.

The other is an external chain chip conveyor.

Due to the strong milling ability of the horizontal machining center, iron filings need to be continuously discharged during the machining process.

So it is very important to choose a reliable chip conveyor.

The horizontal machining center spindle generates a lot of heat during the machining process at high speed.

This heat needs a cooling system to be distributed.

If the heat is not fan in time, the spindle will be damaged by long-term use.

The coolant is generally oil cooled, and the cooling oil is delivered to the inside of the spindle through an oil cooler to reduce its temperature.

Your page rank:

TAICNC is a famous CNC machine brand in the Chinese market. With experience in manufacturing field and strength of technical line, excellent team of engineers, skilled technical workers and rich customer partners in many fields, we are always in the leading position in service quality and price.

08:00 - 18:00 Whatsapp, Skype,WeChat

sales support

B66 Yanhe Rd, Zhangmutou, Dongguan