Are you interested in our CNC drilling and tapping center?

If you are looking for a CNC tapping center, you have come to the right place.

TAICNC is a leading CNC tapping center manufacturer and supplier in China. With 20 years of CNC machine tool manufacturing experience, our CNC machine tools are widely praised by customers around the world.

Whether you need a CNC tapping center, a small machining center, a double column machining center or a vertical machining center, we can meet your needs, our tapping center is suitable for all kinds of metal parts, with a monthly output of more than 200 units, has obtained Apple Supply Chain Recognition. Now on sale at factory price

TAICNC is a CNC tapping center manufacturing specialist. Tapping center is one of our core products, which has the characteristics of high speed, high precision and good stability.

Whether you have industrial use or a personal studio, we have the corresponding CNC tapping center specifications to meet your needs.

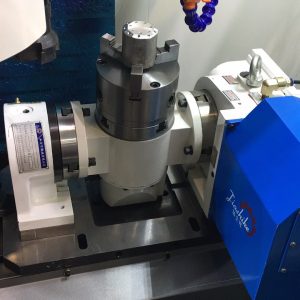

CNC tapping centers are suitable for various industries with powerful performance. You can also choose a standard 3-axis tapping center or choose a tapping center with a 4 axis and 5 axis rotary table to increase the machining efficiency of your product, enabling 4 axis and 5 axis machining.

Selling CNC tapping centers at manufacturer prices, you can get exclusive deals from the best CNC tapping center suppliers in China.

CNC tapping center for sale, you can also contact us to customize special specifications.

Are you interested in our CNC drilling and tapping center?

CNC tapping center is the leader of high-efficiency metal processing machine tools, TAICNC, as a CNC tapping center manufacturing expert, provides high-quality machine tools to many customers.

Our CNC tapping centers are widely used in 3C, electronics, precision parts, medical machinery and other fields. It has won unanimous praise from customers for its excellent milling ability and machining accuracy.

Each CNC tapping center is cast with high-quality casting materials. The design fully considers the actual processing needs, and adopts the best structural design to ensure its accuracy and stability.

At the same time, we have established long-term and good cooperative relations with many excellent core component suppliers. TAICNC CNC tapping center has a small footprint and simple operation, and provides a variety of CNC controller options, such as Siemens, Fanuc, Mitsubishi, SYNTEC, etc.

Our CNC tapping center are designed according to international standards and delivered to customers with guaranteed quality and perfect after-sales service.

CNC tapping center is not a simple machine. Its manufacture requires the support and cooperation of many suppliers. TAICNC has established cooperative relations with many well-known suppliers around the world. We can obtain their quick responses in the supply chain, which enables us to Deliver CNC machine tools to customers in the fastest time.

CNC tapping centers are also called drilling tapping centers or compact machining centers, which also belong to a category of vertical machining centers.

The advent of CNC tapping centers made efficient machining possible.

Compared with the vertical machining center of the same structure, the CNC tapping center has the characteristics of high efficiency, high precision and high stability.

It is widely used in the manufacture of various 3C product parts.

Especially with the advent of smartphones, the demand for CNC tapping centers has surged.

Compared with the traditional vertical machining center, the CNC tapping center has more advantages in processing efficiency.

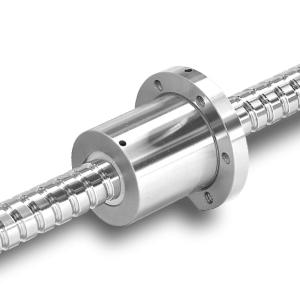

Its unique automatic tool changer and high-speed spindle make CNC tapping centers popular in the market.

Among them, the most famous CNC tapping center manufacturers are Fanuc and Brothers, which have the largest market share in the world. But expensive.

CNC tapping centers work in the same way as vertical machining centers.

Their main role is also milling and drilling

But the CNC tapping center is very advantageous in the drilling process, thanks to its high spindle speed.

In CNC tapping center machining, the workpiece remains stationary while the tool moves along three axes to mill the part. as the picture shows:

3 axis machining remains one of the most widely used techniques for manufacturing mechanical parts and can be used for automated/interactive operations, slot milling, drilling and cutting sharp edges.

You may have never used a CNC tapping center, but when you do, you will find many benefits:

CNC tapping center is a high-efficiency CNC machine tool, its price is cheaper than ordinary vertical machining center, you can use it to complete various complex machining tasks, this machine tool is very cost-effective.

By making fixtures, mass production using CNC tapping centers can be achieved, and with its high-speed spindle and fast traverse speed, efficient mass production can be achieved.

The tapping center is equipped with a 20,000rpm/min direct-drive spindle as standard, the X, Y, Z axis moving speed can reach 48m/min, and the tool change speed only takes 1 second. These conditions create the high efficiency of the tapping center.

Of course, the CNC tapping center not only has advantages, but its disadvantages are also very obvious.

If you look closely, you’ll see that the tapping centers are all relatively small in size, be it the table or the travel.

This is related to the positioning of CNC tapping. The tapping center is mainly positioned for high efficiency and batch processing.

This means that it is not very suitable for heavy milling.

There are many specifications for CNC tapping centers. Even if the specs are similar, the price difference can be quite large. There are many factors that affect the price of the tapping center, as follows:

These factors are closely related to the price of CNC tapping center.

I can give you a price range for your reference as follows:

| Manufacturer or Supplier | Country | Sales Price |

| Brother CNC Tapping Center | Japan | $ 50,000+ |

| Fanuc CNC Tapping Center | Japan | $ 50,000+ |

| TAICNC CNC Tapping Center | China | $ 29,800+ |

The above tapping center prices are for reference only, and the prices will vary greatly due to different configurations.

There are many CNC tapping center manufacturers and suppliers around the world.

Among them, the most famous ones are Brother Tapping Center and Fanuc Tapping Center (Compact Machining Center).

TAICNC is a leading manufacturer and supplier of CNC tapping centers in China, we have provided OEM services for tapping centers for many companies.

If you are interested in our company center, please contact us.

Your page rank:

TAICNC is a famous CNC machine brand in the Chinese market. With experience in manufacturing field and strength of technical line, excellent team of engineers, skilled technical workers and rich customer partners in many fields, we are always in the leading position in service quality and price.

08:00 - 18:00 Whatsapp, Skype,WeChat

sales support

B66 Yanhe Rd, Zhangmutou, Dongguan