Are you interested in our CNC lathe and turning centers?

CNC lathes machine also called CNC turning centers can quickly grow your metalworking business, if you are looking for CNC lathes then you are in the right place.

TAICNC is a leading manufacturer and supplier of CNC lathes machine in China, with more than 20 years of experience in manufacturing CNC machines, our CNC lathe machines are widely praised by customers worldwide.

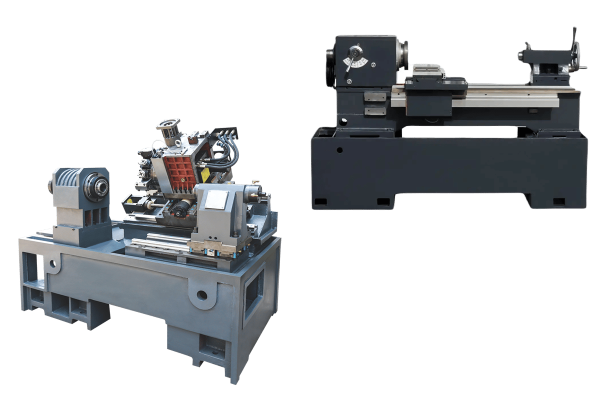

Whether you need flat bed CNC lathe machine, Slanted bed CNC lathe machine, CNC turning centers, turret CNC lathes, we can meet your needs. Our CNC lathe machine are widely used in various metal parts processing and are currently being sold at manufacturer prices.

Slant bed CNC lathe is also called turning center, it is one of the core products of TAICNC, it has the characteristics of high precision, fast speed, strong turning ability and so on.

There are many types of inclined bed CNC lathes we supply, including row tool CNC lathes, turret CNC lathes, turning and milling machines, etc.

Slant bed CNC lathe has powerful turning ability and is widely used in various precision manufacturing. It can complete all the work of turning and milling in one clamping. It is a necessary CNC lathe to improve your production efficiency.

Are you interested in our CNC lathe and turning centers?

TAICNC is an expert in the manufacture of CNC lathes and horizontal turning centers. Each lathe is cast with the best casting materials.

In the design, the actual processing needs are fully considered, and the best structural design is adopted to improve the precision and stability of the CNC lathe.

TAICNC CNC lathes and turning centers are easy to operate, as long as you have operated CNC machines, you can quickly get started. We cooperate with the best CNC controller manufacturers in the market today to provide customers with a variety of economical CNC controllers for customers to choose from.

Our CNC lathe machine are designed according to international standards and delivered to customers with guaranteed quality and perfect after-sales service.

A CNC lathe is not a simple machine, and the manufacture of a qualified CNC lathe requires the support of a large number of suppliers.

TAICNC has established a good cooperative relationship with many well-known suppliers around the world, and we can get their quick response in the supply chain, so that we can quickly deliver CNC lathes to customers. And we stock a large stock of spare parts, so when something goes wrong and needs to be replaced, we can respond quickly and fix the problem.

Do you know about CNC lathe machine?

CNC lathe machine, also known as CNC horizontal turning center, is a kind of metal processing machine.

CNC lathe machine are developed on the basis of manual lathes. Due to trend changes, manual lathes are gradually being replaced by CNC lathes.

CNC lathe machine, like CNC milling machines, are controlled by CNC controllers.

CNC is an acronym for computer numeric control, which refers to a machine operated by a computer system.

CNC lathe machine operate to precise design instructions to machine parts to precise specifications.

Usually one or two centers hold the workpiece, and at least one center can move horizontally to accommodate workpieces of different lengths.

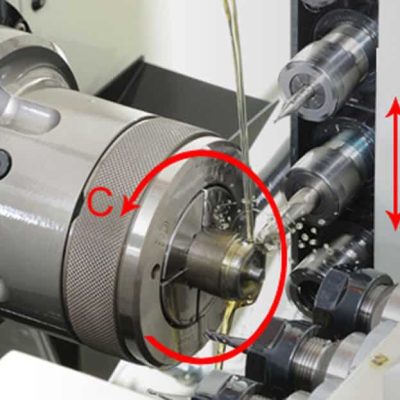

Where the material or part is held in place and rotated by a spindle as the cutting tool working on the material is mounted and moves on each axis.

CNC lathe machine come in many forms and it is by far the most important machine in the field of metalworking

After decades of development, many types of CNC lathes have been derived. The prices of different types of CNC lathes vary greatly, and the actual application scenarios, functions, and the number of tools are very different.

According to the type of structure, it can be divided into the following types:

According to the type of function, it can be divided into:

According to the number of axes can be divided into:

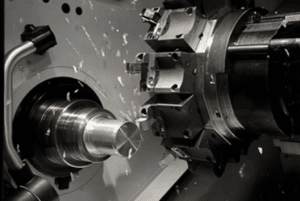

CNC turning is a method of manufacturing that uses computer numerical control (CNC) technology.

CNC turning is used to produce parts by cutting or milling materials, such as metal or plastic.

It can be used to create components with complex shapes, such as gears and shafts, and it can also be used to shape the surface of a material, such as when creating a hole in metal.

CNC turning can be done on a lathe machine, which is known as CNC lathes.

A CNC lathe machine consists of a bed where the workpiece sits, and an axis around which this workpiece rotates while being worked by tools located at different points on the axis.

The toolpath for each operation is programmed into the machine using software called G-code—a type of programming language that tells the machine what operations to perform on each point in space over time according to defined parameters such as speed, feed rate, and depth.

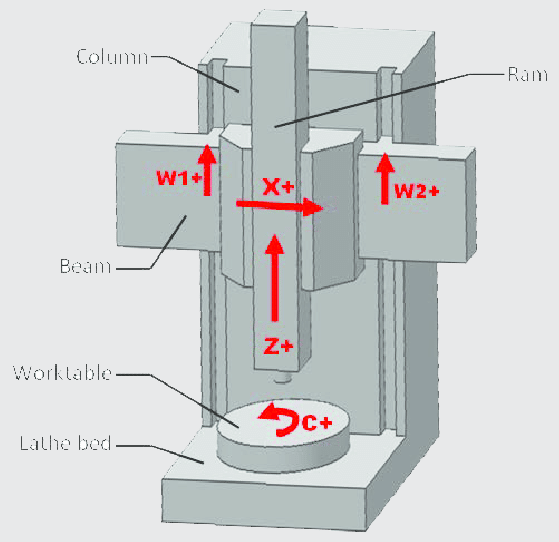

CNC vertical lathe is not a common machine, and its application range is relatively limited.

Vertical lathes have a vertical spindle and a circular table on which the workpiece is mounted.

Since the worktable is in a horizontal position, it is more convenient to align and clamp the workpiece.

Moreover, the gravity of the workpiece and the worktable is borne by the bed guide rail or the thrust bearing, and the main shaft is not easy to bend.

Therefore, the vertical lathe is suitable for processing larger disks and large and short sleeve parts.

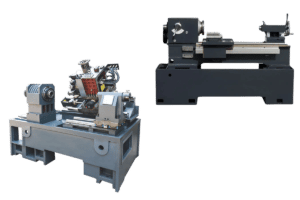

CNC horizontal lathe machine is also called CNC horizontal turning center.

It is one of our most common CNC machines.

A horizontal lathe is a machine tool designed to cut different contours in a rotating steel or wood workpiece.

Its spindle is placed horizontally, so it is called a horizontal lathe.

It is often used to process internal and external rotary surfaces, end surfaces and various internal and external threads of workpieces. It can also be used for drilling, reaming, tapping and knurling with corresponding tools and accessories.

CNC horizontal lathes are controlled by CNC controllers, while ordinary horizontal lathes are manually controlled.

CNC horizontal lathes are suitable for turning various metals and woods.

When the workpiece to be processed is installed in the spindle chuck of the horizontal lathe, the spindle starts to rotate, and the cutter head will move to the side of the part to complete the turning process.

A CNC lathe is not a simple machine, and many components are required to manufacture a qualified CNC lathe or turning center.

Let’s take a look at what are the core components of CNC lathes?

The frame is the foundation of the CNC lathe, and most of the core components of the CNC lathe need to be installed on it.

There are big differences between the different types of frames.

For example, the frame of a CNC vertical lathe is composed of a base and a column, which is somewhat similar to a vertical machining center, while the frame of a CNC horizontal lathe is usually integrally cast.

To ensure longevity, TAICNC manufactures machine beds using high quality Meehanite cast iron. These help to limit heat distortion and provides solid mechanical stability. This ensures that the parts machined are consistently accurate.

The spindle assembly is the most important part of the CNC lathe, and it is the heart of the CNC lathe. It is composed of the spindle box (cast), the spindle assembly, and the motor.

All processing tasks of CNC lathes are completed by the rotation of the spindle, so the quality of the spindle directly affects the processing quality of CNC lathes.

Because it does not require as high a speed as a CNC milling machine, the spindle of a CNC lathe is usually driven by a belt.

Guide rails and screw rods are the moving parts of CNC lathes.

Its quality directly affects the accuracy, rigidity and stability of the CNC lathe.

Usually, the guide rail of flat bed CNC lathe is box type, while the guide rail of inclined bed CNC lathe is linear guide (ball or roller).

The CK series CNC lathes we manufacture all use solid box-type guide rails, which have strong rigidity, while the SCK series all use roller linear guide rails, which have higher precision.

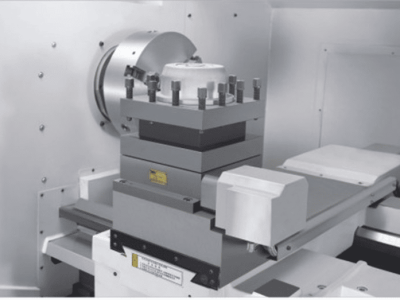

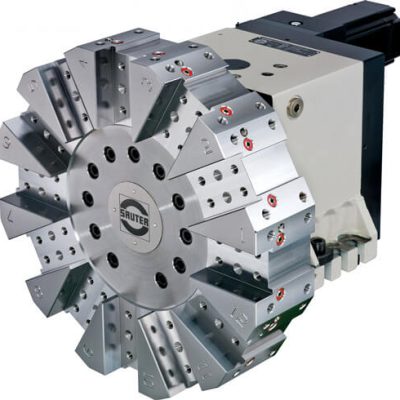

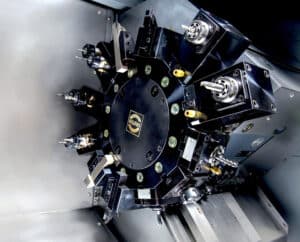

If you are shopping for a CNC lathe in China, you will find that there are many types of tool changers:

Hydraulic tool holders are usually installed on flat bed CNC lathes, and this type of tool holder is economical.

The gang knife is usually installed in the gang knife CNC lathe. This kind of inclined bed CNC lathe is cheaper than the turret lathe.

The turret CNC lathe is the most expensive among the three. Of course, it also has the largest processing efficiency and the largest number of storage tools, and is necessary for processing relatively long shaft parts.

The tool changing device is an important part to improve the machining efficiency of CNC lathes.

Although it is not required, almost all customers will choose it.

Tailstocks are used to provide additional support at the other end of the assembly.

This is necessary when machining long and very long workpieces such as shafts.

There are two kinds of tailstocks: manual tailstock and automatic tailstock.

Whether it is a flat bed CNC lathe or an inclined bed CNC lathe, it can be equipped with a tailstock.

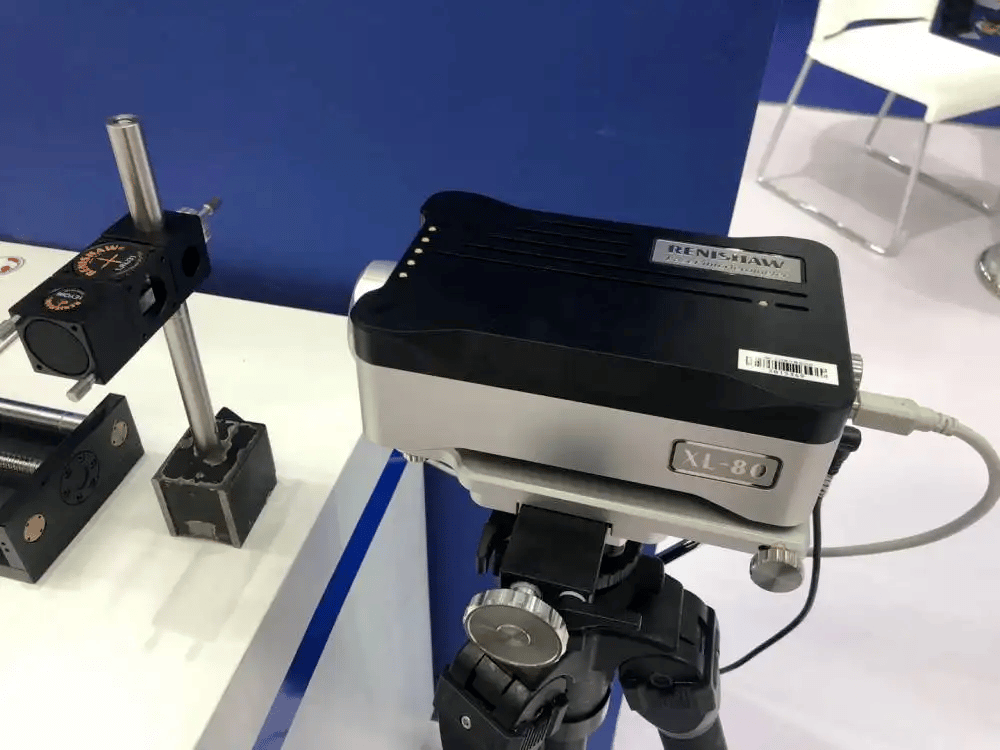

If the spindle is the heart of the CNC lathe, then the CNC controller is the brain of the CNC lathe.

It controls all movements of the CNC lathe.

Different brands of CNC controllers have a great influence on the accuracy of surface gloss.

At present, mainstream CNC controller manufacturers include Fanuc, Siemens, Mitsubishi, Heidenhain, Rexroth, Xintek, GSK, etc.

TAICNC provides a variety of CNC controllers to choose from to meet your usage habits.

The chuck is a vise-like structure that holds the workpiece to be processed. It is attached to the spindle that spins the chuck and workpiece.

Chucks are usually hydraulic, which allows the chuck to maximize grip on the workpiece.

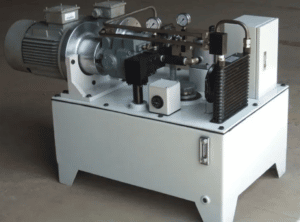

The chuck or tailstock of CNC lathes are usually hydraulic.

Therefore, the hydraulic station needs to provide hydraulic oil for these components.

CNC lathes are not cheap machines, but expensive equipment.

Therefore, the price of CNC lathes is a matter of concern to everyone.

There are many factors that affect the price of CNC lathes, as follows:

transportation cost

Each of these factors is closely related to the cost of CNC lathes.

If you want to buy CNC lathes from China, I will give a price reference range below. Hope this helps you.

You may find a lot of very cheap CNC lathes on the Internet, but remember not to be blindly greedy for cheap, all cheap are based on the premise of sacrificing quality.

A CNC lathe is an expensive and long-term investment.

It is especially important to choose the right CNC lathe.

This largely depends on the following key considerations:

After understanding the above factors, I believe you already have the answer to how to choose a suitable CNC lathe.

All CNC lathes from TAICNC come with 1 year warranty.

In the event of a malfunction, our experts will respond immediately.

Provide you with technical guidance through video, telephone, etc.

If a replacement part is required, we will air freight it and get it to your factory as quickly as possible. We have a large stock of all parts.

If you can’t work it out, we’ll let your local partner handle it.

A lot of friends may worry about the after-sale service when importing machines from other countries.

Will the quality be stable as supplier promises? If any problems, will they help me to solve quickly?

CNC machine is a long-term investment for most companies, to choose an honest and reliable supplier is very important. That’s why we aimed at providing high-quality machines with great customer service for customers.

CNC lathe machines are different from ordinary commodities, and they usually cannot be ordered directly on e-commerce websites such as Amazon or ebay.

You need to contact CNC lathe machine manufacturers and suppliers.

Communicate many details with them.

Such as choosing your nearest suppliers and manufacturers, they will provide you with quotations.

Your page rank:

TAICNC is a famous CNC machine brand in the Chinese market. With experience in manufacturing field and strength of technical line, excellent team of engineers, skilled technical workers and rich customer partners in many fields, we are always in the leading position in service quality and price.

08:00 - 18:00 Whatsapp, Skype,WeChat

sales support

B66 Yanhe Rd, Zhangmutou, Dongguan