Still can’t find your vertical machining center?

If you are looking for a CNC vertical machining center, you are in the right place.

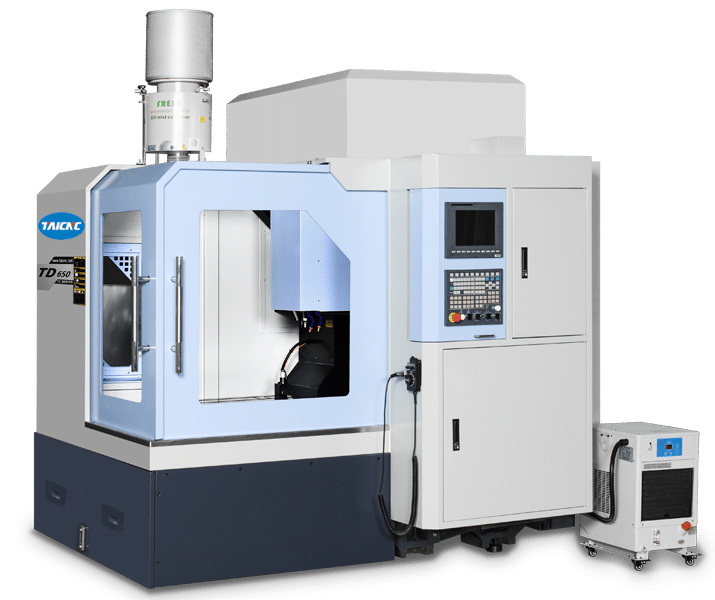

TAICNC is a leading CNC vertical machining center manufacturer and supplier in China. With 20 years of experience in CNC machine tool manufacturing, our VMC machines are widely praised by customers all over the world. Whether you need a vertical machining center, double column machining center or CNC tapping center, we can meet your needs, our vertical machining center is widely used in all kinds of metal parts and mold making and sold at manufacturer prices

TAICNC is an expert in the manufacture of CNC vertical machining centers. We provide vertical machining centers with high quality, accuracy and stability for all walks of life.

Whether you have industrial use or domestic needs, we have a vertical machining center specification to meet your needs.

CNC vertical machining centers can be used in any industry, whether you need a 3 axis vertical machining center, a 4 axis vertical machining center or a 5 axis vertical machining center, we have you covered.

Sell Vertical Machining Centers at manufacturer prices, you can get exclusive deals from the best Vertical Machining Center suppliers in China.

Still can’t find your vertical machining center?

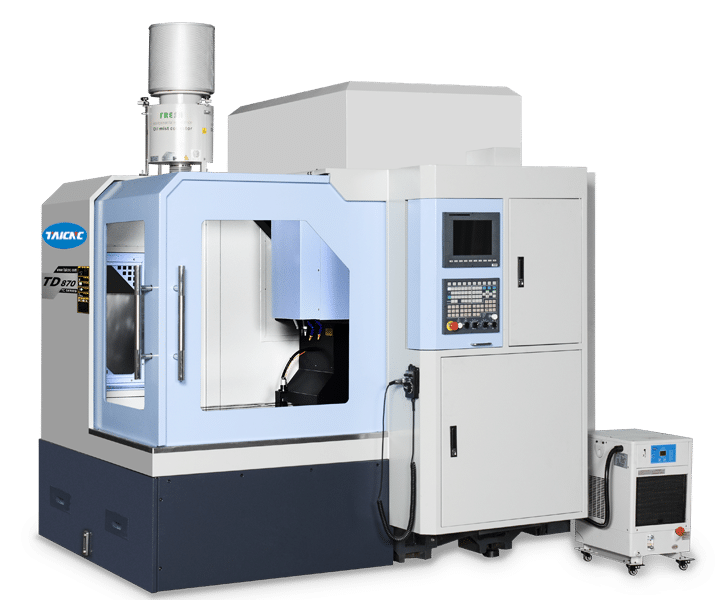

TAICNC, as an expert in the manufacture of vertical machining centers, each vertical machining center is cast with high-quality casting materials.

In the design, the actual processing needs are fully considered, and the best structural design is adopted to improve the precision and stability of the CNC machine tool.

TAICNC vertical machining center is easy to operate, as long as you have operated CNC machine, you can get started quickly. We cooperate with the best CNC controller manufacturers on the market today to provide customers with a variety of economical CNC systems to choose from. Such as Fanuc, Siemens, Mitsubishi, SYNTEC, HEIDENHAIN, etc.

TAICNC vertical machining center provides a variety of taper spindle options, such as BT, BBT, HSK and other spindle types.

The transmission mode can choose belt type, direct connection type, gear type and so on. The equipped spindles all have the characteristics of high rigidity, and the maximum spindle speed ranges from 6000 to 24000 rpm.

CNC controller is the brain of CNC vertical machining center. Our VMC machine is equipped with popular CNC controller, which is convenient for operators to use quickly and skillfully.

Including a variety of economical CNC controllers and high-end CNC controllers, they all have excellent performance and can meet the needs of your machine tools in actual work.

Our vertical machining centers are designed according to international standards and delivered to customers with guaranteed quality and perfect after-sales service.

CNC vertical machining center, also known as VMC machine, is the most common CNC machine tool in metal parts manufacturing. It is developed on the basis of CNC milling machine.

Many people think that the CNC vertical machining center just adds an automatic tool changer to the CNC milling machine.

In fact, it is true that although CNC vertical machining center and CNC milling machine are two different names, in fact, their functions are the same, they are both used for milling and drilling.

CNC vertical machining centers are very useful machines for both commercial and industrial production.

The aerospace, medical and electronics industries can all benefit from CNC milled products, what makes them so unique?

CNC stands for Computer Numerical Control Milling.

This essentially means that the milling machine is controlled by a digital computer rather than being moved and monitored manually.

CNC milling tools perform processes similar to drilling and cutting parts with incredible precision, so there is no room for human error.

The process is an increasingly popular industrial solution because it can accommodate detailed sizes and shapes of various materials.

If you are still using a manual milling machine I think you should pay attention to the CNC vertical machining center. It is more precise and efficient, and it is your best friend in metalworking.

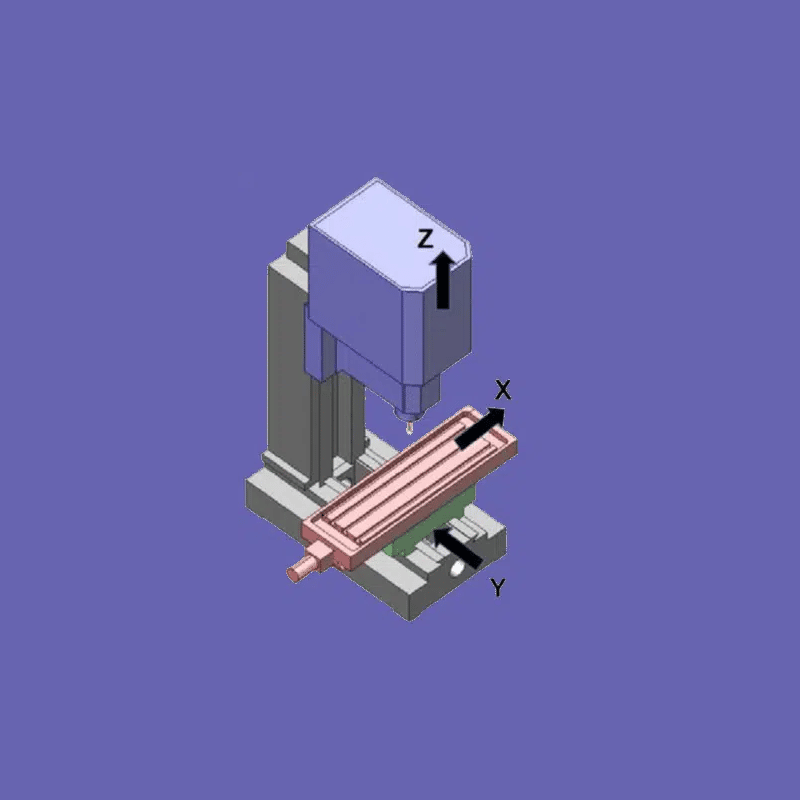

Usually a CNC vertical machining center consists of three axes, X, Y, and Z, and its structure is that the main shaft moves vertically downward.

CNC vertical machining centers can be divided into the following types according to application scenarios:

CNC vertical machining centers can be divided into the following types according to the number of axes:

In fact, the working principle of CNC vertical machining center is the same as that of CNC vertical milling machine. Their main job is milling and drilling.

Of course, different types of vertical machining centers have differences in the size and type of parts processed.

For example, CNC double-column machining centers can process the largest parts and molds, such as automotive molds.

The CNC 4 axis vertical machining center and the CNC 5 axis vertical machining center can complete the machining of multiple faces in one clamping, and the 5 axis machining center can complete more complex precision machining, such as impellers.

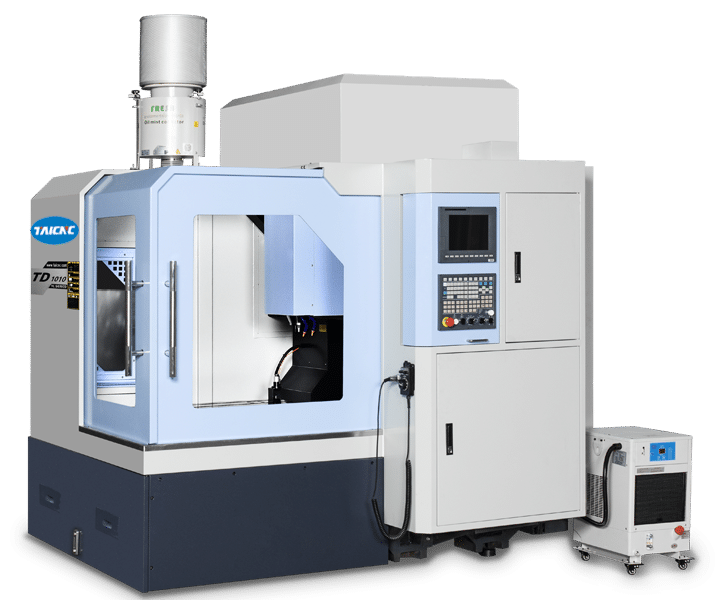

Our most common CNC machining center is the 3 axis vertical machining center.

The 3 axes in the CNC 3 axis vertical machining center represent the X, Y, and Z axes in the vertical machining center.

Among them, the X axis can move left and right, the Y axis can move forward and backward, and the Z axis can move up and down.

3 axis milling evolved from the practice of rotary filing, and is a milling process that operated on two axes, the X & Y axis.

In 3 axis vertical machining center, the workpiece remains still while the cutting tool moves along the three axes to mill the part.

3 axis machining still one of the most widely used techniques to create mechanical parts, and can be used for automatic/interactive operation, milling slots, drilling holes, and cutting sharp edges.

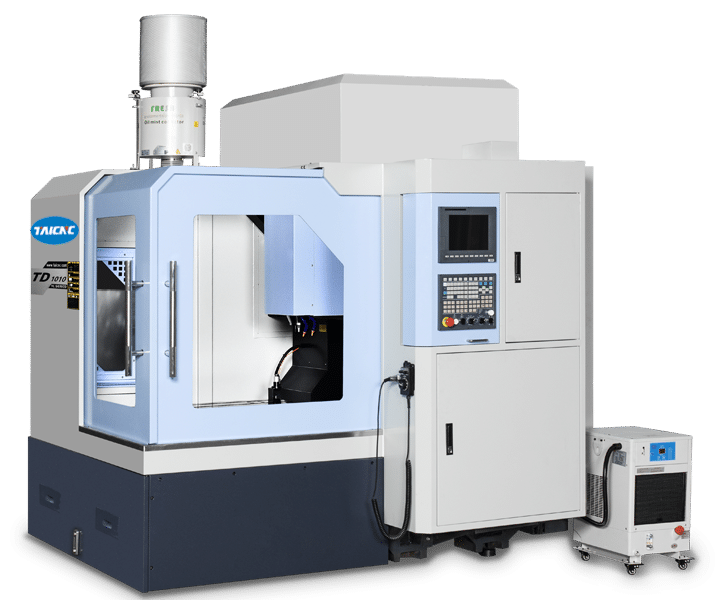

4 axis machining center is evolved on the basis of three axis.

4 axis CNC machining center includes four movable axes X, Y, Z, A

In fact, the 4-axis machining center adds a rotary table to the X-axis of the 3-axis machining center. As shown in the video.

Usually a 4-axis vertical machining center can process multiple faces of a part in one clamping, reducing the number of clamping and improving the processing efficiency.

Many customers choose a 4-axis rotary table when purchasing a machining center, which is also our recommended option.

5 axis machining center is also called 5 axis CNC milling machine.

Here we mainly explain the CNC 5 axis vertical machining center, which is mainly composed of five axes: X, Y, Z, B, and C.

There are generally three types of 5-axis vertical machining centers:

A 5-axis CNC machine has two extra rotary axes which opens the door to an infinite number of machining possibilities.

The types of rotary axis include rotary axes A, B and C which rotates around the X-axis, Y-axis, and Z-axis respectively.

While these are three extra axes and not two, they’re still considered 5 axes in total.

The combination of the additional axes is machine dependent and can come in any combinations of AB, AC or BC.

When using a CNC vertical machining center, you will find its many benefits, as follows:

Cost-effectiveness

CNC vertical machining centers can bring you higher machining efficiency, you do not need to have a worker for each vertical machining center like manual milling machines. One worker can operate multiple VMC machines at the same time. CNC vertical machining centers are more efficient, which makes it more profitable.

mass production

Master the operation of CNC vertical machining center, can realize mass production by making fixtures, and complete the processing of multiple products at one time.

more accurate

CNC vertical machining center is controlled by CNC controller and equipped with servo motor, which enables the vertical machining center to complete more precise machining and reduce errors.

There are a lot of specifications for CNC vertical machining centers. Even with similar specifications, the price difference may be relatively large. There are many factors that affect the price of vertical machining centers, as follows:

These factors are closely related to the price of vertical machining centers.

If you choose to buy a vertical machining center in China, I can give you a price range for your reference, as follows:

The above only lists the prices of 3 axis vertical machining center, 4 axis vertical machining center and 5 axis vertical machining center.

Among them, the price range of 5 axis vertical machining centers is relatively large, mainly due to the high price of 5 axis machining centers, and the prices of different types of 5 axis machining centers vary greatly.

How to choose the right CNC vertical machining center is a good question.

Most newbies don’t know how to choose a vertical machining center that suits them.

After all, a vertical machining center is not a cheap piece of equipment but an expensive investment.

Here are some key considerations for how to choose the right vertical machining center:

I believe that after understanding the above questions, you should have the answer to how to choose a suitable vertical machining center.

CNC vertical machining center consists of some core parts. This includes the following—

The frame is the basis of the CNC vertical machining center.

All other core components of a vertical machining center are mounted on the frame.

Different types of vertical machining centers have different frame structures.

The frame is usually cast from cast iron. The vertical machining center frame consists of two parts, one is the column and the other is the base.

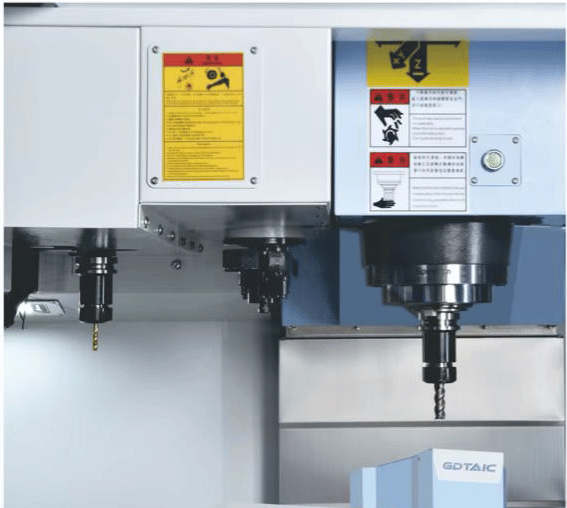

Spindle is one of the core components of CNC vertical machining center. All machining tasks are performed by the rotation of the spindle.

There are many types of spindles, such as BT, BBT, HSK, etc. The tool holders used by different types of spindles are different.

The spindle transmission mode and spindle speed are also very important. The common spindle transmission methods are:

Belt spindle

Direct drive spindle

Built-in electric spindle

Gear spindle

Screws and guides are the core components of the CNC vertical machining center movement.

Its quality affects the accuracy and running speed of the vertical machining center.

The screw rods and guide rails used by TAICNC are made by Rexroth, Germany.

We have established good cooperative relations with many screw guide brands.

Different brands of CNC controllers have a greater impact on the surface gloss accuracy.

Servo motors and drives for CNC vertical machining centers are usually matched with CNC controllers.

The power of the servo motor determines its torque, and the torque affects the processing of the CNC milling machine.

At present, the most widely used CNC controllers are FANUC, Mitsubishi, Siemens, Rexroth, Heidenhain and SYNTEC.

Automatic Tool Changer Affects Machining Efficiency of Vertical Machining Center

Automatic tool changer is the core equipment of CNC vertical machining center.

Although it is not necessary, it is very helpful for improving processing efficiency.

Avoid the need to frequently change tools in the actual machining process.

The high-speed rotation of the spindle of a vertical machining center generates a lot of heat during machining.

This heat requires a cooling system to fan the heat.

If it is not fanned in time, the spindle will be damaged if it is used for a long time.

The coolant is usually oil-cooled, and the cooling oil is transmitted to the inside of the spindle through an oil cooler to reduce its temperature.

But whether a cooling system is needed mainly depends on the spindle speed. Usually, the spindle with the maximum spindle speed below 12,000rpm/min does not need oil cooling.

Vertical machining centers are constantly moving during work.

The lubrication system is to provide continuous lubrication for these movements to reduce wear on the lead screw and guide.

The lubrication system will work intermittently according to the set time.

Your page rank:

TAICNC is a famous CNC machine brand in the Chinese market. With experience in manufacturing field and strength of technical line, excellent team of engineers, skilled technical workers and rich customer partners in many fields, we are always in the leading position in service quality and price.

08:00 - 18:00 Whatsapp, Skype,WeChat

sales support

B66 Yanhe Rd, Zhangmutou, Dongguan