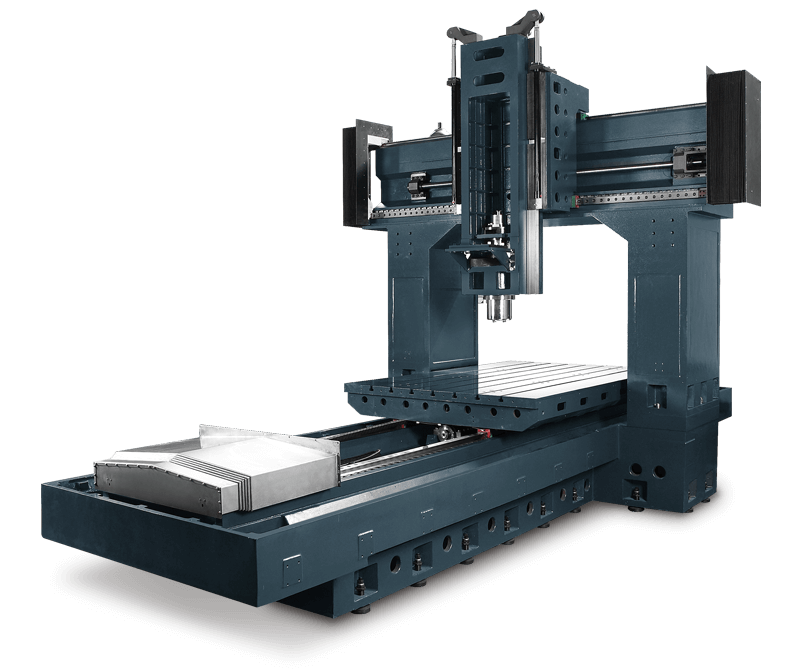

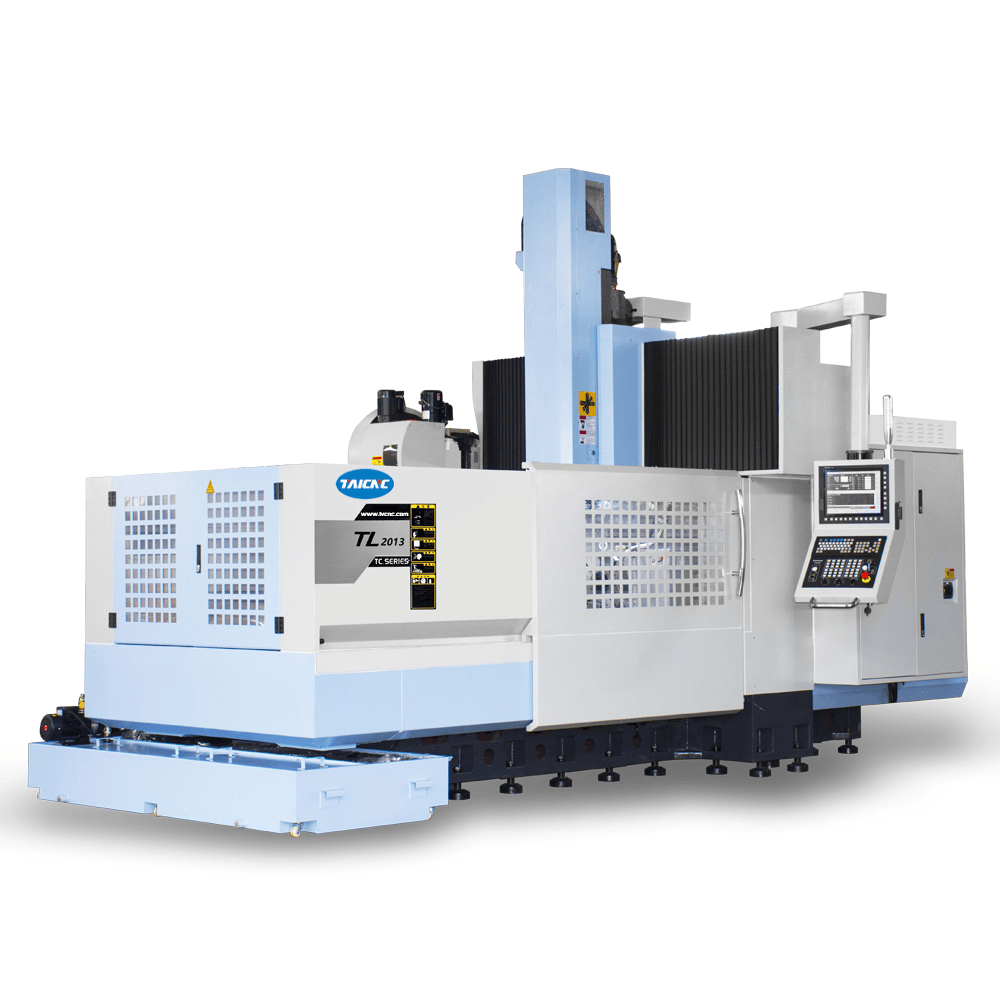

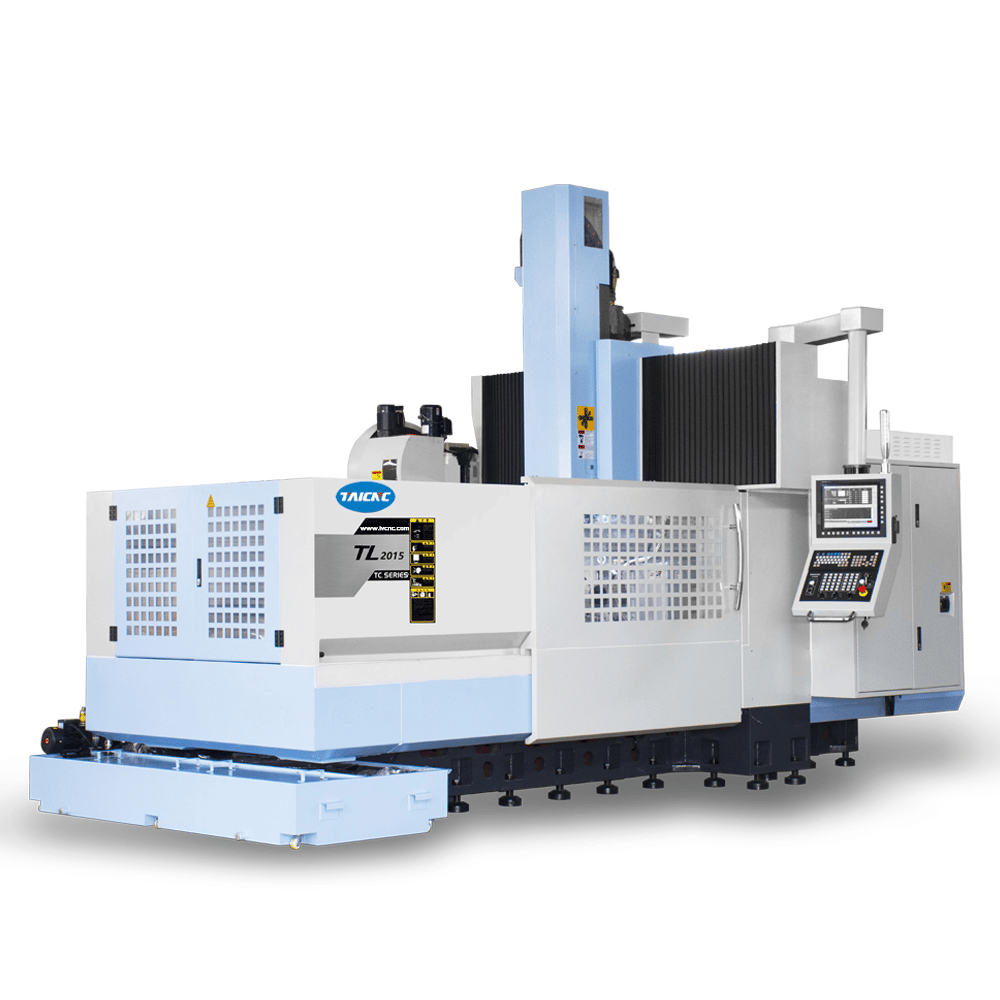

double column machining centers have many names. Some people call it a double-column CNC milling machine. Some people call it a gantry machining center. It is a large CNC machine used for milling metal.

double column machining center is used to replace large vertical machining centers. It has a larger work table and processing range, which is very suitable for the production of large workpieces and molds.

TAICNC’s CNC double column machining center has been designed with precision analysis and excellent machine structure to enhance the design of the beam and the base. Their high efficiency and precision can help you get the job done.

TAICNC is a leading manufacturer and supplier of double column machining centers in China, and we are experts in this field.

Double Column Machining Center video

This video demonstrates the perfection of a 4-axis double column machining center for the completion of automotive parts. The double column machining center is suitable for the machining of large workpieces.

Best casting material

CNC double column machining center uses the best casting materials, major structural parts are manufactured from high quality Meehanite cast iron (GB 300+), tempered for stress relief with hardness over 190HB.

Good casting materials make the machine more robust and stable.

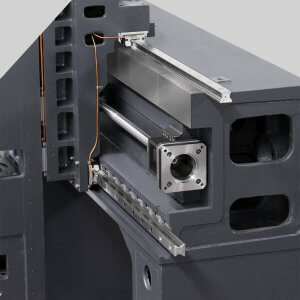

Best head design

The machine head is a very important part of double column machining center. This double column CNC milling machine head adopts the best design and uses Inverted L type machine head with modified cross-ribs to increase bending and torsion resistance. It improves the overall processing rigidity and stability.

The best gantry pillar

Excellent column gantry type machining in order to ensure rigidity and stability of the machine, this CNC double column machining center using Integrated casting and double-layered strengthened ribs gantry type column to ensure the cutting rigidity.

Thickened honeycomb body structure base design

Good base design can ensure better stability of CNC double column milling machine and avoid vibration caused by insufficient rigidity during processing.

This CNC double column machining center uses Double layered box type base to ensure high stability and rigidity.

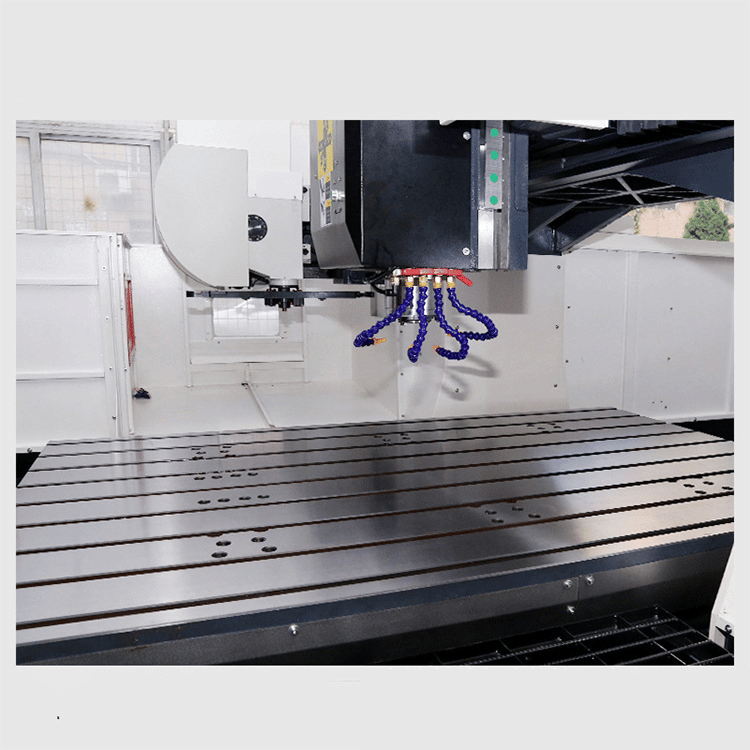

Large span ladder type guideway

The CNC double column machining center requires heavy milling, which requires him to be very rigid.

The double column machining center uses Ladder type large span Y axis guideway, the guideway is distributed on the front and top of the beam, increasing the bearing capacity of guideway.

High rigidity linear guide

This CNC portal milling machine is equipped with high-rigidity roller guides. The brand is made by Taiwan HIWIN or German Rexroth. The roller guides have better rigidity. The 3-axis movement speed can reach 15/min. It is very fast for such large machine tools.TC-1613L Gantry Milling Machine the box type constructed base is mounted with 4 linear ways, making the machine capable of resisting heavy loads, additional benefits are its increased feed rate and higher positioning accuracy.

High precision roller screw

Ball screw with is a very important part of double column machining center. It affects the accuracy of machine tools. This machine uses C3 grade high precision ball screw with pre-extension process, improve the transmission rigidity and machine accuracy.

precision ballscrews are made through a grinding process of the screw spindle. Precision ground ballscrews provide high positioning accuracy and repeatability, smooth movement and long service life. These highly efficient ballscrews are a perfect solution for a variety of applications.

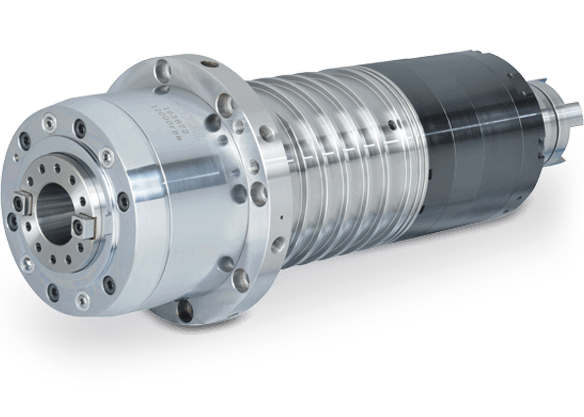

High rigidity belt spindle

This CNC double column machining center is equipped with BT40 12000rpm/min high rigidity direct connection spindle, and can also choose 18000rpm/min high-speed Built-in spindle. It has high precision and the surface finish of the finished workpiece is very good.

The short nose spindle presents outstanding rigidity. It also may increase efficiency while lowering tool wear.

High speed automatic tool changer

It is equipped with a 24-bit BT40 automatic tool changer, which makes it more efficient and can automatically replace the required tool according to the processing requirements.

Auto Chip Conveyor

The machine is also equipped with 2 spiral automatic chip removal machines capable of effectively the strips, blocks and granules,clear the internal debris of the machine.

Equipped with well-known brand CNC controller

The CNC controller is the brain of CNC mill. This double column machining center has four brands of CNC controllers to choose from. They are Taiwan SYNTEC/Germany Siemens/Japan Mitsubishi/Japan FANUC, and they all have rich experience in CNC controller manufacturing. , high market share, and provide complete technical manuals.

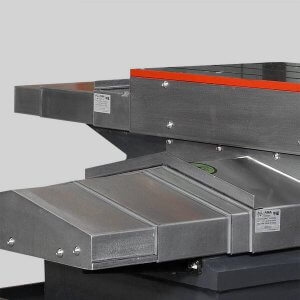

3 axis precision protective cover

CNC double column machining center will continue to produce iron filings during the machining process, which will damage the machine. This CNC double column machining center 3 shaft is equipped with a precision protective cover to prevent iron filings from damaging the machine during production.

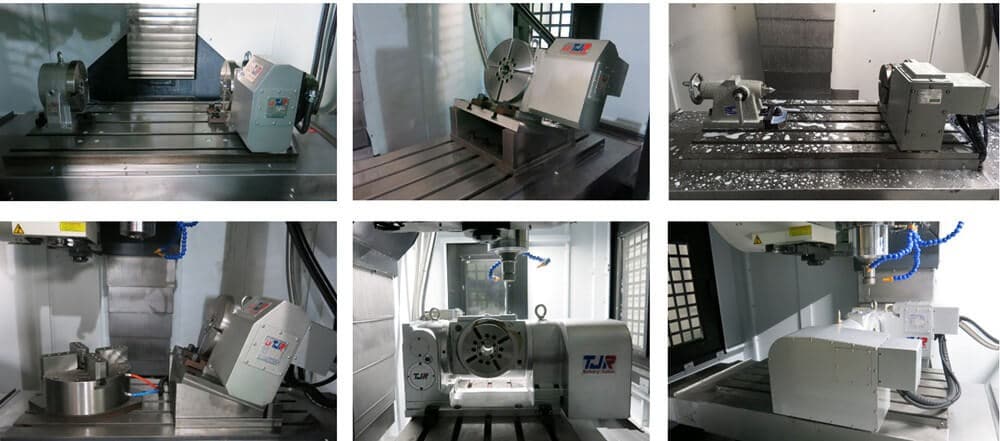

Multi-axis linkage can choose

CNC double column machining center can choose the CNC rotary table to realize the functions of 4 axes and 5 axes, which makes it have higher processing efficiency. All the processes can be completed in one clamping, but it is not necessarily required for each workpiece. Specific, choose according to the products you need to manufacture.

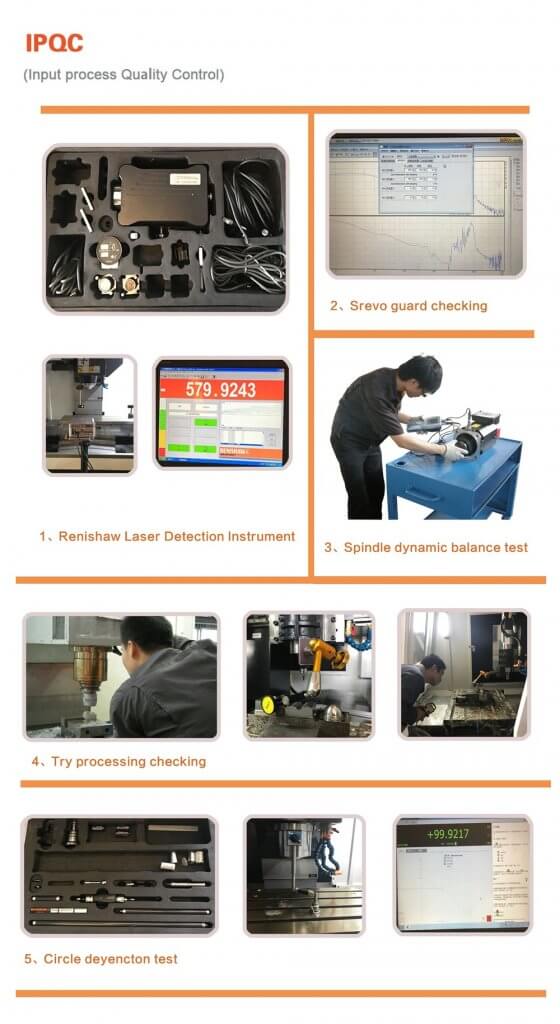

Quality management

Every machine tool produced by TAICNC is produced in strict accordance with the ISO standard. During this process, a variety of quality management tests will be carried out. We must ensure that all the CNC machine tools delivered to our customers are qualified and perfect.

A sophisticated laser unit is employed to inspect the three-axis accuracy.Including linear positioning, positioning, accuracy, pitch error, and backlash, etc.

use a ball bar tester is employed for inspecting servo accuracy, static and dynamic geometric errors.

Production sample

CNC milling machine can do a lot of work this is only part of it, it can process a lot of materials such as copper, aluminum, steel, Bakelite and so on, can be used in various fields, if you are not sure Whether to meet your requirements welcome to contact us.

About packaging and shipping

We use strict packaging for all machine tools to ensure that it will not be damaged during transportation. We have good cooperation with many transportation companies. We must ensure that the machine can be transported safely and on time to your factory.

TAICNC certificate

TAICNC has passed the ISO9001 / 14001 certification and CE certification, obtained a number of national patents, and strictly comply with manufacturing standards.

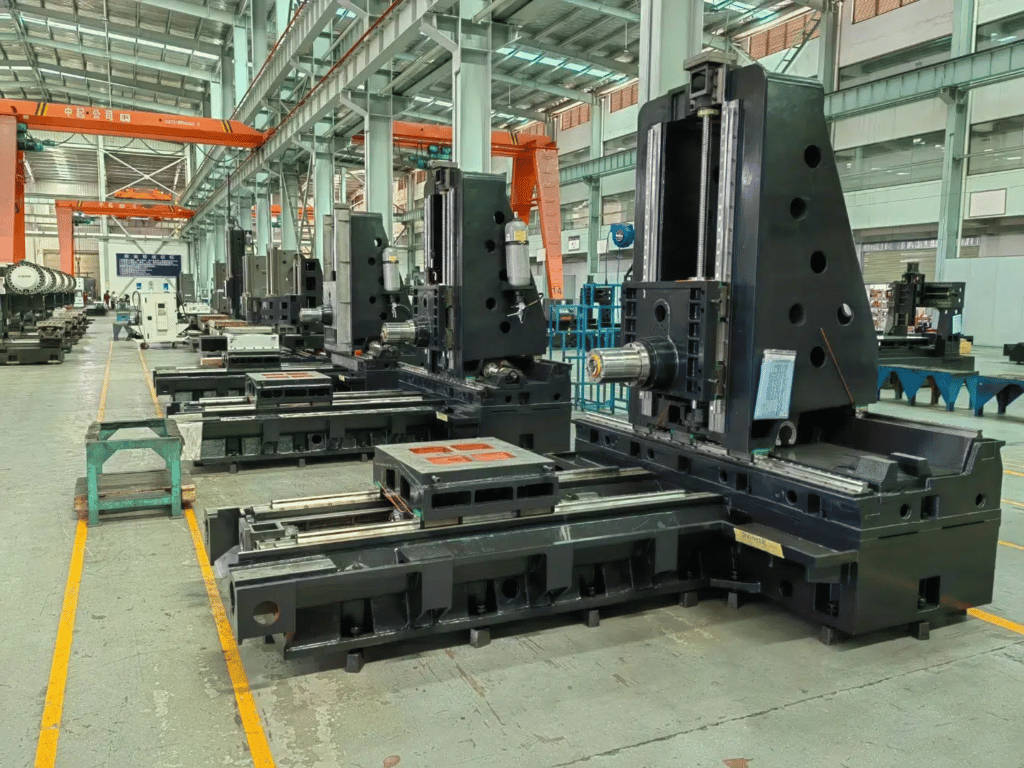

TAICNC manufacturing factory show

We have a sound management system and a clean factory, which is the first condition to ensure product quality.

2 thoughts on “TL-1613L Double Column Machining Center”

VMC TL1613 CATLOG SEND ME AND PRIES FOB

Hi MR. J K PATEL, we have sent a quotation please check your mail.