When choosing a CNC mill, how many axis do you need for the CNC milling machine? It’s a problem for every CNC mill buyer, so, let’s get into what the differences between 3 axis, 4 axis and 5 axis CNC milling machine.

Learn about 3 Axis, 4 Axis and 5 Axis CNC Milling Machine

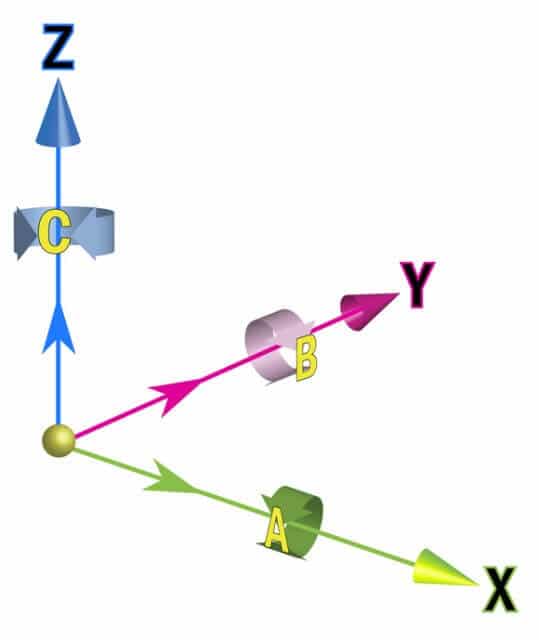

- 3 Axis: X-Y-Z (3 Axis linkage)

- 4 Axis: X-Y-Z-A, X-Y-Z-B, X-Y-Z-C (4 Axis linkage)

- 4th Axis: Y-Z-A, X-Z-A (3 Axis linkage) ABC is corresponding to the rotation axis of XYZ

- 5 Axis: X-Y-Z-A-B, X-Y-Z-A-C, X-Y-Z-B-C (The spindle can be rotated 180 degrees to the left or right or the turntable can be rotated 360 degrees, swinging 180 degrees back and forth.)

ABC is corresponding to the rotation axis of XYZ.

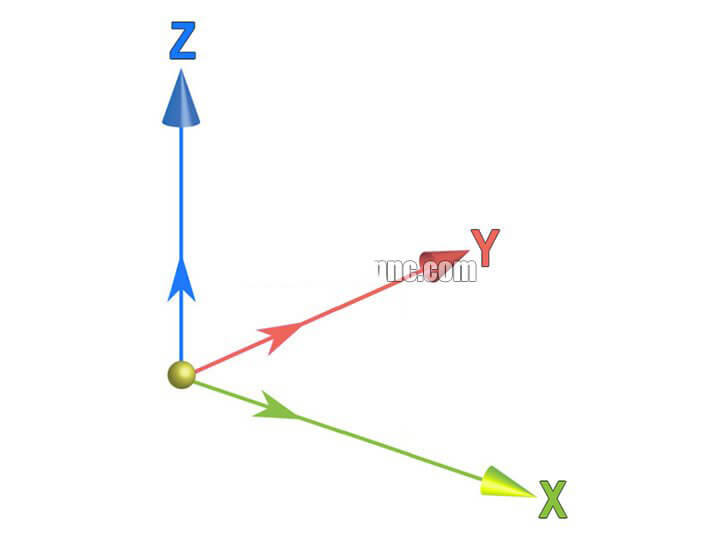

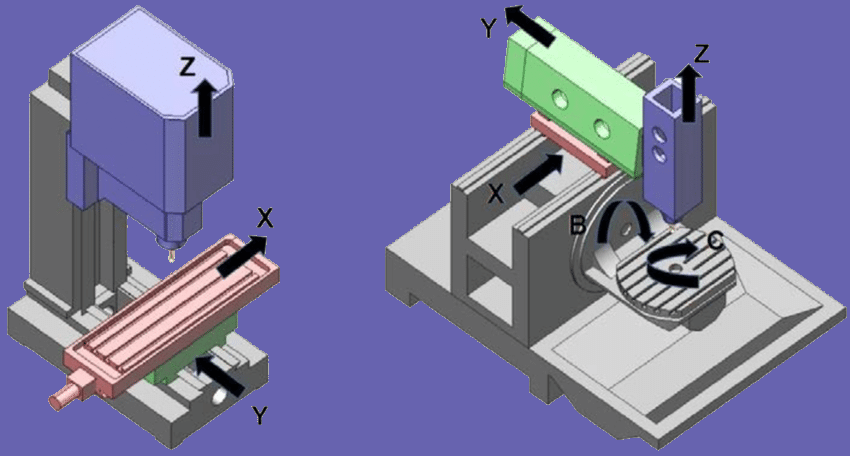

3 Axis CNC milling machine

These specific CNC mills can go along three different axis at the same time.

- X-axis: left to right

- Y-axis: front to back

- Z-axis: up and down

3 axis CNC mill moving three axis at the same time; the X-axis, the Y-axis, and the Z-axis. Cutting along the X-axis moves the CNC milling machine bit from left to right, cutting along the Y-axis moves it from front to back, and cutting across the Z-axis moves it up and down. These CNC machines are used primarily for cutting flat, 2D and 2.5D parts.

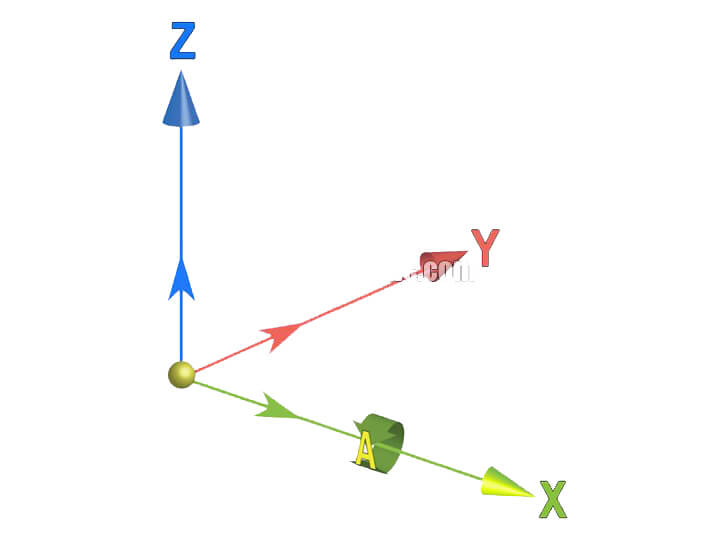

4th Axis CNC Mill

Generally, add a rotation axis on the 3 axis CNC milling machine, also called A-axis, that is, 4 axis 3D CNC mills. how to distinguish a real 4 axis CNC milling machine? We give a common example of 4 axis engraving, milling threads on a cylinder, this work has 4 axes, but only work with 3 axis system, it is used X axis or Y axis to drive the rotation axis,the real work is a 3 axis CNC mill or a 4 axis 3 linkage CNC milling machine.

4 axis CNC milling machine makes work possible on both sides, which is not on 3 axis CNC mill. The 4 axis machine tools also have XYZ axis, it refers to the XYZA, XYZB, XYZC, 4 axis are linked, the 4 axis can work at the same time.

5 Axis CNC Mill

There are many types of 5-axis CNC milling machines. 3+2 and swing 5-axis CNC milling machines are common.

It’s important to distinguish between 5-axis machining and 3+2-axis machining. The former—also called continuous or simultaneous 5-axis machining—involves continuous adjustments of the cutting tool along all five axes to keep the tip optimally perpendicular to the part

In contrast, the latter—also called 5-sided or positional 5-axis machining—involves executing a 3-axis program with the cutting tool locked at an angle determined by the two rotational axes. Machining that involves reorienting the toolbar along the rotational axes between cuts is called ‘5-axis indexed’ though it still counts as 3 + 2.

The main advantage of continuous 5-axis machining over 5-axis indexed is speed, since the latter necessitates stopping and starting between each reorientation of the tool whereas the former does not.

However, it should be possible to produce the same results whether using continuous or indexed 5-axis.

It’s also worth noting that with the speed advantage comes more moving parts, which leads to increased wear and tear as well as a greater need for part crash detection. This is one of the reasons continuous 5-axis machining is more difficult from a programming standpoint.

Which CNC Mill is ideal for you?

While these milling machines seem somewhat straight forward with what they can accomplish, they are very delicate and advanced pieces of technology. If you are looking to get more creative with your designs, it is recommended you invest in a 4 axis CNC mills or 5 axis CNC mills, but 3 Axis mills or 4th axis CNC mills are often more affordable.

Now that you have a working knowledge of how a CNC mill works you can better understand the differences between various models.

5 axis CNC mill can cut along two additional axis than 3-axis CNC mills. These routers have the ability to cut on five sides of a piece of material simultaneously, which expands the operator’s capabilities and flexibility. Unlike their 3 axis counterparts, these machines are usually used to cut large 3-dimensional parts.

Although the CNC milling machine seems like simple machines, they are highly sophisticated pieces of technology that require a certain level of expertise to operate. 5 axis CNC mill tend to be more expensive than traditional 3 axis CNC mill, but ultimately offer greater flexibility and enable users to be more creative with their designs.